Evaluation of in-situ stress in dense sandstone reservoirs in the second member of Xujiahe Formation of the HC area of the Sichuan Basin and its application to dense sandstone gas development

-

摘要:研究目的

四川盆地HC地区须二段勘探开发潜力巨大,但该地区为典型的低孔低渗致密气藏,需要进行地应力精细评价来为后期纵向上压裂选层和平面上工程甜点区优选提出建议进而提高产能。

研究方法基于25组声发射和13组差应变等实验测试分析,结合水压致裂、常规和特殊测井资料,进行地应力的精细评价,以期分析在致密砂岩储层中不同实验测试方法的适用性,查明有利于工程改造的层位和甜点区。

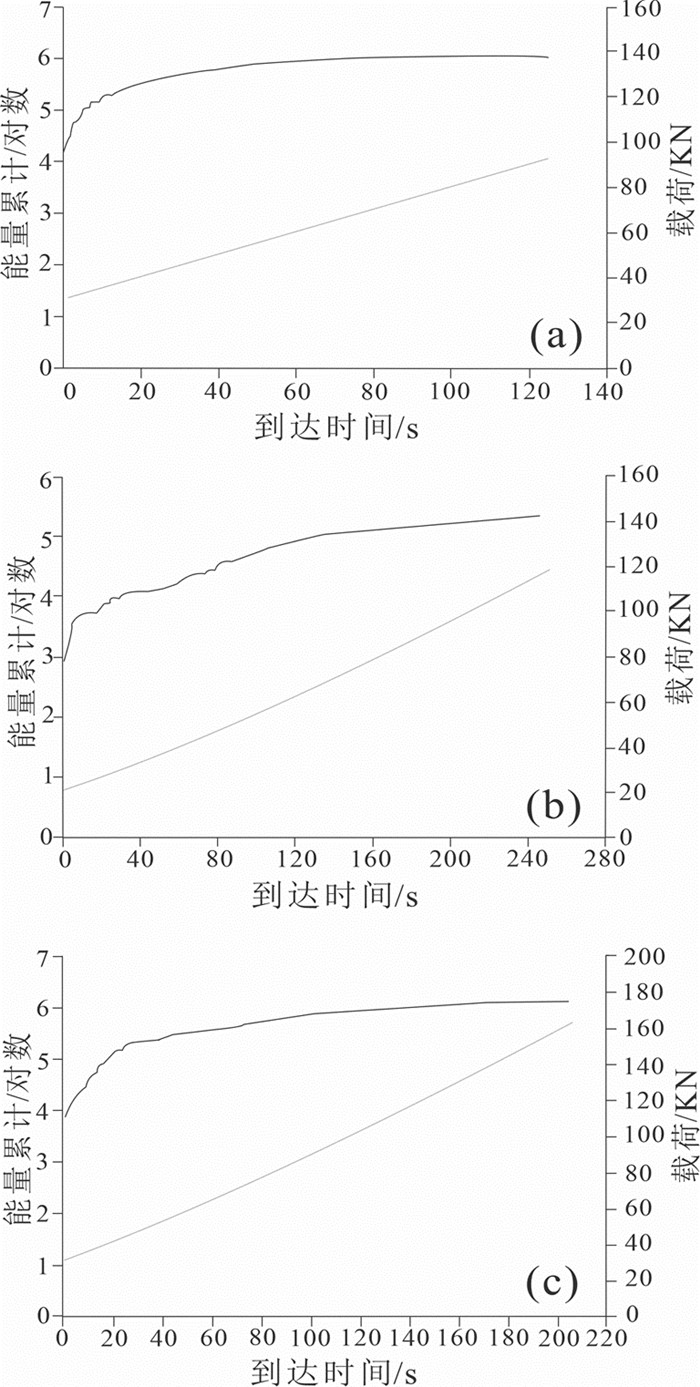

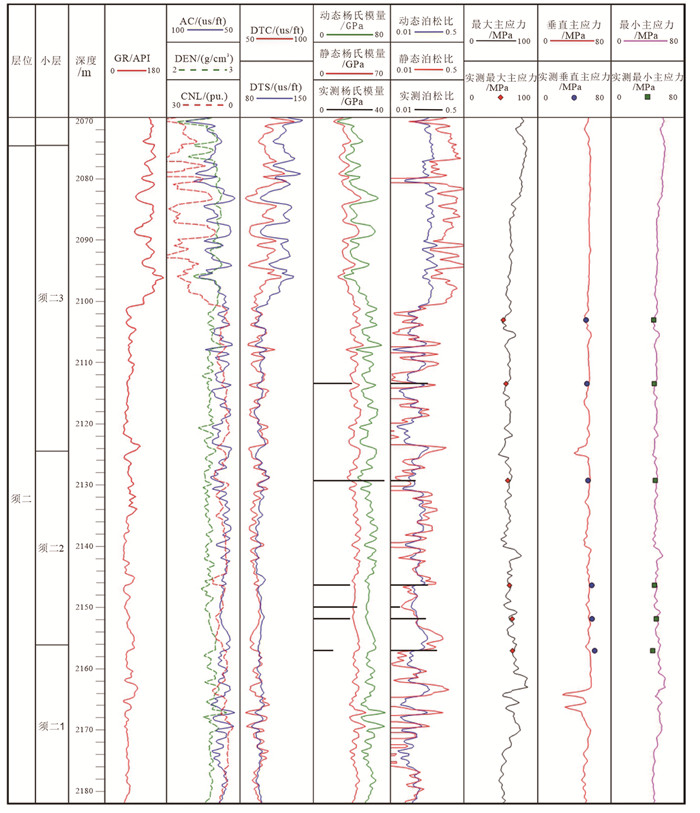

研究结果实验测试结果表明HC地区须二段最大水平主应力值为50.77~75.65 MPa,均值为59.71 MPa;最小水平主应力值为45.37~54.31 MPa,均值为49.31 MPa;垂向主应力为48.11~65.62 MPa,均值为56.53 MPa。模拟结果表明储层内部应力隔层厚度和两向应力差异系数越小,越有利于压裂改造。通过对比小层间的三向应力关系,表明须二段处于走滑应力状态。HC地区须二段致密砂岩均质性较强,声发射测试结果误差较大,差应变测试结果与其他地应力大小解释结果具有更高一致性,故该测试方法更加适用于均质性较强的砂岩地层。

结论结合地应力大小,纵向上建议选择隔层组合更有利的须二2亚段中上部为压裂目的层;且为了达到较好的体积缝网压裂改造效果,平面上建议避开两向应力差异系数较大的断层附近区域,应选择优质储层发育且水平应力差异系数相对较小的HC地区中部HC102-HC111井区。

创新点:揭示了差应变测试相比于声发射测试更加适用于均质性致密砂岩储层地应力大小测量;隔层应力结构与水平应力差异系数共同控制了HC地区须二段“工程甜点”的分布。

Abstract:This paper is the result of oil and gas exploration engineering.

ObjectiveThe second member of Xujiahe formation of the HC area in the Sichuan Basin has great potential for exploration and development, but it is a typical low-porosity and low-permeability tight gas reservoir, which requires in-situ stress refined evaluation to recommend the optimal selection of engineering sweet spots for later vertical fracturing and plane fracturing to increase production.

MethodsBased on experimental test analysis such as 25 groups of acoustic emission and 13 groups of differential strain, combined with hydraulic fracturing, conventional and special logging data, we analyze the applicability of different experimental test methods in tight sandstone reservoirs by performing a fine-scale evaluation of in-situ stress and identified layers and sweet spots conducive to engineering modifications.

ResultsThe results of the experimental tests of the second member of Xujiahe formation in the HC area showed that the maximum horizontal principal stress values ranged from 50.77 to 75.65 MPa, with a mean value of 59.71 MPa; the minimum horizontal principal stress values ranged from 45.37 to 54.31 MPa, with a mean value of 49.31 MPa; and the vertical stress values ranged from 48.11 to 65.62 MPa, with a mean value of 56.53 MPa. The simulation results show that the smaller the thickness of the stress barrier within the reservoir and the differential coefficient of in-situ stress in both directions, the more favorable the fracture modification. The comparison of the three-dimensional stress relationships between the minor layers indicates that the second member of Xujiahe Formation is in a strike-slip stress state. The dense sandstone in the second member of the Xujiahe Formation is more homogeneous, the acoustic emission test results are more inaccurate. The results of the differential strain test are in better agreement with the results of the in-situ stress magnitude interpretation, making the test method more suitable for more homogeneous sandstone formations.

ConclusionsIn combination with the magnitude of in-situ stress, it is recommended vertically that the more favorable combination of compartments, upper middle of the second subsection of Xu-Ⅱ, be selected as the target layer for fracturing. To achieve a better volume fracturing network, it is recommended to avoid areas near faults with a large differential coefficient of two-dimensional stress. The area of HC102-HC111 well in the central part of the HC area, where high-quality reservoirs are developed and two-dimensional stress difference factor is relatively small, should be selected.

-

1. 引言

鄂尔多斯盆地陕北地区长8油层组是近年来油气勘探新的后备领域,在姬塬、西峰、镇北、马岭地区都发现了大规模油藏,展示出巨大勘探前景。陕北地区长8段属东北沉积物源体系,砂体发育,储层孔隙度平均值为8.45%,渗透率平均值为0.12 × 10-3μm2,为典型的低孔超低渗致密储层(图 1),并且紧邻长7段烃源岩,在志丹一带发育长9段烃源岩,平面上油水分布关系复杂,成藏期次以及石油聚集关系不明确,长期制约着石油勘探开发。近年来不少学者对鄂尔多斯盆地长8石油成藏机理及分布规律进行了研究,区域多集中于陇东和姬塬地区,前人认为伊陕斜坡构造简单,延长组油藏主要受沉积相控制,发育岩性油藏(赵靖舟等,2006);盆地长7油层组与长8油层组之间存在的过剩压力差是油气纵向运移的主要驱动力,横向上过剩压力低值区为油气运聚成藏的有利区(楚美娟等,2013;姚泾利等,2015);把姬塬地区长8油层划分为五种成岩相,认为层序界面控制了早期的溶蚀作用和碳酸盐胶结作用(赖锦等,2014)。相比较而言,陕北地区长8研究主要包括烃源岩、低幅度构造、储盖组合、运移动力等方面(王维斌等,2017;任瑞清等,2017),石油成藏条件分析薄弱,尤其是借助流体包裹体对成藏时期各个关键时刻与油气聚集关系的分析少有涉及。

目前确定成藏时间的主要技术包括生排烃史法、油藏地球化学法、饱和压力法、流体包裹体均一温度、自生伊利石K-Ar法、Re-Os元素测年法等(刘德汉等,2007;陈梦娜等,2018),其中,流体包裹体是矿物结晶生长时,被包裹在矿物晶格缺陷的成矿流体。流体包裹体形成后,由于既没有外来物质的加入也没有自身物质的流出,因而可以作为原始的成矿流体进行研究。流体包裹体方法最初主要应用于矿床学的研究,20世纪70年代末到80年代初随着石油地球化学的发展,流体包裹体已作为一种重要的手段应用于石油地质研究,并且逐渐发展成为最广泛和最有效的手段之一。从目前的应用情况看,流体包裹体应用于石油地质研究主要有两个方面:一是根据包裹体均一温度测定数据以及捕获温度、捕获压力的计算资料,研究盆地烃源岩的热演化历史和储层的成岩演化历史;二是根据各类烃包裹体的观测分析资料,剖析油气生成—运移—聚集的成藏信息(赵桂萍,2017)。

本文利用流体包裹体分析技术,厘定了陕北地区长8成藏年代时间,结合该区热演化史和埋藏史,对油藏聚集的规律进行分析,明确了下一步勘探的主要方向。

2. 流体包裹体特征

沉积物沉积、成岩演化各阶段形成的新生矿物、矿物加大边、碎屑矿物裂隙的愈合面,以及矿物、岩石的重结晶等都可能捕获沉积、成岩环境中的介质流体,而所形成的各种包裹体记录着地质演化的历程信息。储层成岩自生矿物组构、相互包裹、穿插关系和形成时间序列,油气包裹体相态、形态、颜色、分布、均一温度和荧光特征等均记载了地质演化信息(赵彦德等,2016)。

2.1 样品采集和处理

本次研究,共选择了陕北地区中生界延长组长8的12口井32个砂岩样品,岩性主要为岩屑长石砂岩,在中国石油兰州石油地质研究所实验研究中心进行了包裹体测温。受包裹体分布的影响,在23个样品薄片中检测到了油包裹体,并对荧光光谱和均一温度进行测试。

流体包裹体透光和荧光分析在MPV-SP显微镜光度计上进行。其中,流体包裹体均一化温度测试对象主要为石英次生加大边和方解石胶结物中与油包裹体共生的盐水包裹体,若无油气包裹体,则选择盐水包裹体测量。

2.2 包裹体荧光光谱特征

目前对包裹体荧光光谱进行定量描述的参数主要有主峰波长和红绿商两种。其中,主峰波长(λmax)指最大荧光强度(Imax)所对应的发射波长,它随着小分子成分含量的增加,成熟度增大,荧光会发生明显的“蓝移”,光谱主峰波长减小;反之,光谱主峰波长增大;红绿商(QF535和Q650/500)指荧光颜色中红色部分与绿色部分的比值,可以定量化描述荧光光谱形态和结构。QF535为发射波长535~750 nm范围内的积分面积与发射波长430~535 nm范围内的积分面积之比,Q650/500为650 nm波长处荧光强度与500 nm波长处荧光强度的比值。QF535和Q650/500值越大,反映石油的成熟度越低,反之,成熟度越高(付金华等,2017)。

本次实验由于游离烃荧光强度较弱,无法进行光谱特征测试,重点对石英、长石和碳酸盐胶结物等不同宿主矿物内的包裹烃进行荧光光谱特征分析。结果表明,长石包裹体烃的主峰波长值最大,为477.2~532.8 nm,平均494.2 nm,石英包裹体烃较小,主峰波长为472.0~529.1 nm,平均为488.4 nm,碳酸盐胶结物中包裹体烃最小,主峰波长为459.3~ 488.0 nm,平均为477.0 nm。红绿商在长石包裹体中平均值为0.208,在石英包裹体中为0.194,在碳酸盐胶结物烃中为0.173(表 1)。因此,不同包裹体烃的荧光光谱主峰波长和红绿商参数变化趋势一致,长石和石英包裹体烃的数值较大且差距不大,而碳酸盐胶结物烃值最小。

表 1 陕北地区长8储集层部分包裹体荧光光谱参数特征Table 1. Characteristics of fluorescence spectrum parameters of inclusions in Chang 8 reservoir in northern Shaanxi

2.3 包裹体类型、分期

根据镜下薄片、扫描电镜等观察,陕北地区长8储集砂岩经历了多种成岩作用,压实作用中等—强压实程度,可见长石等碎屑颗粒紧密接触、颗粒定向排列或塑性岩屑变形,石英及长石颗粒的加大边现象普遍,高岭石含量较低,绿泥石分布形态以绿泥石环边、薄膜为主,长石和岩屑溶蚀普遍但发育程度不高,铁方解石及铁白云石胶结明显。研究区长8成岩序列可以概括为:压实作用→石英、长石次生加大→伊利石、高岭石沉淀→长石、岩屑溶蚀→高岭石胶结、自形石英微晶→铁方解石、铁白云石胶结(王维斌等,2017;叶博等,2018)。

在以上成岩作用序列基础上,对研究区长8储层中流体包裹体的物理相态、颜色、形态及分布情况进行镜下观察,长8储集层油气包裹体大致可分为早、晚两期,分别代表两次油气运移、成藏事件。第一期包裹体主要分布在石英碎屑颗粒的石英次生加大边以及石英颗粒内部裂隙,偏光下为褐色,无荧光或者很淡的黄色荧光,反映包裹体形成较早。第二期包裹体主要分布在切穿石英颗粒裂隙周缘,主要呈现成串的珠状定向分布,外形以椭圆或者不规则状为主。该期包裹体具有黄色荧光,荧光较强,形成时间相对较晚(图 2)。

![]() 图 2 陕北地区长8储层包裹体镜下特征a—石英加大边中气液包体,Q108,1165.2 m;b—石英溶蚀孔隙中气液包体,Q108,1165.2 m;c—石英中气液包体,Q130,1712.3 m;d—长石中浅黄色气液包裹体(荧光),Q108,1165.2 m;e—石英晚期裂隙,烃类包裹体,X94,2209.5 m;f—石英晚期裂隙,有烃类充注(荧光),X94,2209.5 m;g—石英裂隙中的包裹体,S220,2046.4 m;h—石英裂隙中有机液+盐水包裹体,X85, 1907.3 m;i—石英裂隙中气液包裹体,Q130, 1712.3 mFigure 2. Microscopic characteristics of inclusions in Chang 8 reservoir in northern Shaanxia-Gas-liquid inclusion in quartz enlarged edge, Q108, 1165.2 m; b-Gas-liquid inclusions in quartz dissolution pores, Q108, 1165.2 m; c-Gas-liquid inclusions in quartz, Q130, 1712.3 m; d-Light yellow gas-liquid inclusions in Feldspar (fluorescence), Q108, 1165.2 m; e-Inclusions in quartz fractures, X94, 2209.5 m; f- Inclusions in quartz fractures with hydrocarbon filling (fluorescence), X94, 2209.5 m; g-Inclusions in quartz fractures, S220, 2046.4 m; h-Inclusions of organic liquid and brine in quartz fractures, X85, 1907.3 m; i-Gas-liquid inclusions in quartz fractures, Q130, 1712.3 m

图 2 陕北地区长8储层包裹体镜下特征a—石英加大边中气液包体,Q108,1165.2 m;b—石英溶蚀孔隙中气液包体,Q108,1165.2 m;c—石英中气液包体,Q130,1712.3 m;d—长石中浅黄色气液包裹体(荧光),Q108,1165.2 m;e—石英晚期裂隙,烃类包裹体,X94,2209.5 m;f—石英晚期裂隙,有烃类充注(荧光),X94,2209.5 m;g—石英裂隙中的包裹体,S220,2046.4 m;h—石英裂隙中有机液+盐水包裹体,X85, 1907.3 m;i—石英裂隙中气液包裹体,Q130, 1712.3 mFigure 2. Microscopic characteristics of inclusions in Chang 8 reservoir in northern Shaanxia-Gas-liquid inclusion in quartz enlarged edge, Q108, 1165.2 m; b-Gas-liquid inclusions in quartz dissolution pores, Q108, 1165.2 m; c-Gas-liquid inclusions in quartz, Q130, 1712.3 m; d-Light yellow gas-liquid inclusions in Feldspar (fluorescence), Q108, 1165.2 m; e-Inclusions in quartz fractures, X94, 2209.5 m; f- Inclusions in quartz fractures with hydrocarbon filling (fluorescence), X94, 2209.5 m; g-Inclusions in quartz fractures, S220, 2046.4 m; h-Inclusions of organic liquid and brine in quartz fractures, X85, 1907.3 m; i-Gas-liquid inclusions in quartz fractures, Q130, 1712.3 m早期包裹体其物理相态主要有气态烃+液态烃+少量盐水、气态烃+液态烃和纯液态烃3种。气液比较大,颜色为黑色或深褐色;气态烃呈灰色,在包裹体中央部位;液态烃为黄褐色,半透明;盐水无色透明,分布在包裹体边缘。这类包裹体形态为近圆形、椭圆状,部分为不规则状,常常见于溶蚀孔隙中,沿早期裂隙呈串珠状分布,形成于沉积埋藏之后。

晚期油气包裹体物理相态主要包括气态烃+液态烃+大量盐水及气态烃+大量盐水2种。所捕获的油气包裹体较大,其包裹体形态主要为椭圆型和不规则状,多呈串珠状分布。油、气、水3种相态边界清晰可见。这类包裹体主要分布在晚成岩阶段的裂隙,同时在晚期硅质胶结物和亮晶方解石胶结物中也可见,荧光颜色较浅,反映出有机质流体中烃类含量相对较低(时保宏等,2012)。

陕北地区长8储层中的两期油气包裹体主要分布在与多期构造运动有关的构造裂隙和溶蚀孔隙中,燕山运动和喜山运动两期裂隙形成(曾联波等,2007;郭川等,2009)与当时的构造活动息息相关,而构造活动是成岩作用和油气形成以及运移成藏的主要因素。因此,两期油气包裹体分别代表了研究区两次油气运移成藏过程,油气运移与早、晚期构造活动有关(万永平等,2010;张莉等,2019)。

3. 包裹体均一温度和盐度

流体包裹体均一温度是指气-液两相流体变为单一均匀相流体时所需的温度,烃类包裹体由于甲烷的存在容易散失氢离子,从而改变包裹体的成分,造成所测的均一温度与捕获时的均一温度不同。与烃类包裹体同幕的盐水包裹体均一温度分布不仅可以用来作为古温度的近似值和热事件的标志,而且还可以用作油气成藏幕次划分的有效依据,是了解流体古温度、推测盆地古地温和热演化史的主要依据。盐水包裹体分幕依据有两点原则:一是具有相同产状和相似气/液比的流体包裹体组合;二是相似产状和相似气/液比包裹体内部均一温度大致按15℃间隔分幕(陶士振,2006)。因此,与烃包裹体共生的盐水包裹体能够提供自生矿物结晶时古地层流体的温度,利用流体包裹体均一温度作分析研究时,通常采用的都是盐水包裹体(陈刚等,2012)。

陕北地区长8储层流体包裹体类型主要包括盐水包裹体和含液态烃包裹体。本次在成岩自生矿物序次分析基础上,选取与油气包裹体相伴生的盐水包裹体测定其均一温度,以判别不同充注期形成的包裹体,测点数共计326个。统计数据后发现,储层包裹体均一化温度集中在80~140℃内(图 3),虽然分布范围较宽,但都主要存在85~105℃和115~135℃两个峰值区间,分布连续,表明油气为连续充注,整个充注过程未发生大的构造事件,而出现两个峰值说明该区烃类充注是一个由强到弱,再由弱到强的连续充注过程,为两期成藏过程(白玉彬等,2014)。

流体包裹体盐度可反映沉积时流体的环境,通常开放系统中的流体盐度要低于封闭系统中的流体盐度,它的大小是根据流体包裹体中水溶液的冰点温度来测得计算的。结果表明,长8砂岩储集层包裹体盐度总体较低,呈不对称偏态分布,一般在1%~7%,盐度整体在1%~5%,分别有2%~3%和4%~5%两个峰值区间,也进一步证明了陕北长8砂岩储层存在两期流体包裹体。同时,流体包裹体盐度变化范围较广,说明地层流体交换作用很普遍。

4. 包裹体恢复石油成藏时期

近些年来,流体包裹体广泛应用于油气成藏研究,尤其是基于流体包裹体测温与热演化史相结合间接确定油气成藏期次的研究,有力推进了油气成藏年代学的定量研究。

4.1 热演化史恢复

受区域构造演化历史的控制,陕北地区中生代经历了多期次的构造运动,构造变形与燕山运动和喜马拉雅运动密切相关。盆地东缘的基本构造形态在燕山运动期形成,受到古太平洋板块与亚洲大陆俯冲产生的远程构造效应的影响,主要表现为NW-SE向挤压作用,区内发育一系列NE-NNE走向的开阔平缓的背斜带和单斜构造;新生代以来,由于印度板块向欧亚板块的碰撞和碰撞期后的陆内俯冲所产生的远程效应,盆地东缘古构造应力场挤压方向由燕山期的NW-SE向转变为NE-SW向(王锡勇等,2010;赵振宇等,2012)。在鄂尔多斯盆地多旋回沉积与多阶段抬升改造的区域背景下,研究区中新生代经历了多期非匀速的快速沉降沉积过程与强度不等的构造抬升剥蚀事件(丁超等,2016)。

目前利用流体包裹体分析是确定油气成藏时期的主要方法,它是将包裹体测温数据投射到沉积埋藏史与古地温场演化史图上,然后进一步确定地层流体达到相应温度的地质历史时间、地质年代。

盆地热演化史控制着油气成藏时期,详细的埋藏史及热史恢复对油气成藏研究的不同方法得出的结果有限定作用,可以提高成藏期次研究的精度,使之更符合实际。地层埋藏史及其地层温度的演化过程史是包裹体定年的依据,将包裹体均一温度数据与盆地热史中温度的演化史进行对比,可以判定油气运移成藏的时间。研究区长8包裹体均一化温度主要分布在80~140℃,热演化埋藏史如图 4所示。

4.2 石油成藏时期

由包裹体均一温度分布特征来看,分布范围较宽,集中在85~105℃和115~135℃两个峰值区间,分别对应晚侏罗世—早白垩世。陕北地区主要发育长7烃源岩,从热演化历史的模拟结果看,侏罗纪晚期—白垩纪早期延长组烃源岩的 Ro值接近0.7%,达到生烃门限,可以大规模生烃。将构造演化史同油气包裹体宿主矿物与均一温度、Ro值结合起来,参照任战利等(2007)测定的鄂尔多斯盆地古地温梯度3.68℃/100 m和地表温度15℃计算,得出研究区延长组长8应为连续一期两幕成藏。结合长8地层埋藏−热演化史图,推测长8储层包裹体形成时间距今135~110 Ma,对应的地质时间为早期充注时间的晚侏罗世和大规模充注期的早白垩世两个时期,这也与前人对于鄂尔多斯盆地延长组油气成藏时期的研究相吻合(任战利,1996;柳益群等,1997)。

5. 石油成藏模式

成藏模式是对具有代表性油藏特征的油气成藏作用充分而且高度的概括与归纳,在同一成藏模式中的油藏应该具有相似的成藏作用和成藏特征。成藏模式是在充分解剖典型油气藏、明确油藏形成条件和成藏特征的基础上建立的,对指导下一步勘探方向具有启示意义。

陕北地区成藏地质条件主要包括烃源岩展布与厚度、剩余压力、沉积砂体、储层物性、顶面构造等因素(陈世加等,2012;王奇等,2018),如果各成藏地质条件及生油关键时刻配置良好,就能形成有利的油气富集区。由以上埋藏和热演化史分析可知,陕北地区在早白垩世最大生排烃阶段构造相对稳定,生成的油气不易被后期构造破坏,是形成大型油气藏的有利条件,因而影响该区石油富集的最主要的因素为烃源岩、储层及充注动力等因素。本次从烃源岩出发,以包裹体充注时间为纽带,以输导体系为重点,建立陕北地区长8石油成藏模式。

烃源岩是油气生成的物质基础。鄂尔多斯盆地三叠系延长组长7、长9暗色泥岩为该区主要烃源岩(图 5),长9烃源岩在志丹一带局限分布(师磊等,2011)。两种烃源岩相比较,最有利的生烃来源仍然是长7,其有机母质类型为Ⅰ~Ⅱ1型,有机质丰度4.10%~9.23%,镜质体反射率Ro为0.8~1.4,处于成熟阶段,厚度为10~35m,具有机质丰度高、类型好的特征。研究区长8油藏是最有利于石油富集的层位,其分布主要受生烃中心的展布以及厚度控制,即距长7生烃中心越近,成藏越好,越远则越差,长7、长9泥岩厚度分布在平面存在差异,因此暗色泥岩厚度大的地区往往是有利的勘探目标区。

![]() 图 5 陕北地区长7、长9烃源岩与长8油藏分布图(据任瑞清等,2017)Figure 5. Source rock distribution in Chang 7 and Chang 9 and reservoir distribution in Chang 8 in northern Shaanxi (modified from Ren Ruiqing et al., 2017)

图 5 陕北地区长7、长9烃源岩与长8油藏分布图(据任瑞清等,2017)Figure 5. Source rock distribution in Chang 7 and Chang 9 and reservoir distribution in Chang 8 in northern Shaanxi (modified from Ren Ruiqing et al., 2017)延长组长8为三角洲沉积体系,三角洲前缘水下分流河道砂体和三角洲平原分支河道砂体发育,局部砂体具有厚度大,连片性强的特点。储层特征也是制约石油聚集的关键因素,其主要受沉积环境的控制,现今陕北地区长8砂岩储层压实和胶结作用是储层致密化的重要原因。结合埋藏史,从晚侏罗世研究区进入快速埋深压实阶段,原生孔隙迅速降低,在早白垩世埋深达到最大。长7、长9烃源岩生成的石油选择物性相对较好的储层聚集成藏。通过统计,吴起地区砂岩储层平均孔隙度为8.9%,渗透率平均为0.25×10-3μm2,高桥—西河口地区储层平均孔隙度为7.2%,渗透率平均为0.16×10-3 μm2,前者工业井明显多于后者,很好地验证了以上由于储层物性变化明显,油气差异聚集的结论。

从油包裹体分析来看,研究区砂岩储层普遍具有含油气荧光显示,只是荧光颜色有区别,反映了油气充注强弱不同。本文利用含油包裹体颗粒指数(GOI=含油包裹体颗粒数/颗粒总数×100%)对陕北地区长8充注程度进行了分析,该指数用于识别古油藏及石油运移路径等,储层石油包裹体丰度大于5%则为油层或古油层,小于5%为低充注或主要输导层(陈梦娜等,2018)。由于样品数量限制,只对7个含油包裹体样品做了GOI分析,其中有3个GOI值大于5%,都分布在吴起一带,说明该区总体石油充注强度较大,但在其他地区GOI值小于5%,分析认为可能是由于距离长7主力烃源岩远,长9生烃能力有限,储层非均值影响,石油充注程度不高,长8储层中滞留大量地层水,测试过程中往往产水(图 6)。

鄂尔多斯盆地中生界延长组砂岩主要为低渗透储层,前人通过对运移动力的研究,认为影响该区油气大规模成藏的主要动力为由于泥岩欠压实作用形成的过剩压力(楚美娟等,2013;姚泾利等,2015),长7烃源岩生成的油气在过剩压力驱动下,通过近源叠置的砂体和周围裂缝向下运移至长8砂岩储层成藏,甚至运移至下覆长9、长10地层。在典型油气藏解剖的基础上,综合油藏分布、类型、输导体系、充注程度等因素,认为长8原油主要富集在邻近烃源岩的相对高孔高渗的水下分支河道、河口坝等砂体中,其中西部(吴起—顺宁)长8原油来自上覆长7烃源岩,东部(志丹—高桥)长8原油主要来自于原地下伏长9烃源岩,具有“双源供烃,差异聚集”的成藏特点(图 7)。

6. 结论

(1)长8砂岩储层中的流体包裹体主要分布于细砂岩的石英加大边或裂隙中,以气液烃包裹体、气液两相盐水包裹体为主,可分为早、晚两期,与气液烃包裹体伴生的盐水包裹体均一温度主要存在85~105℃和115~135℃两个峰值区间,分布范围广,油气为连续充注。

(2)陕北地区长8石油充注的主要时期为110~135 Ma,分别为晚侏罗世的早期充注和早白垩世的大规模充注两个时期。主要发育长7烃源岩,晚侏罗世—早白垩世期间延长组烃源岩的Ro值均接近1.0%,达到生烃门限,可以大规模生烃,长9烃源岩在志丹地区局部分布。

(3)陕北长8油藏受烃源岩、储层及充注动力等因素控制,发育岩性油藏,在平面上分布不均匀。西部吴起—顺宁地区长8含油包裹体颗粒指数GOI值多大于5,油藏相对东部志丹—高桥地区分布更多,区域上具有“双源供烃、差异聚集”的成藏特点。

-

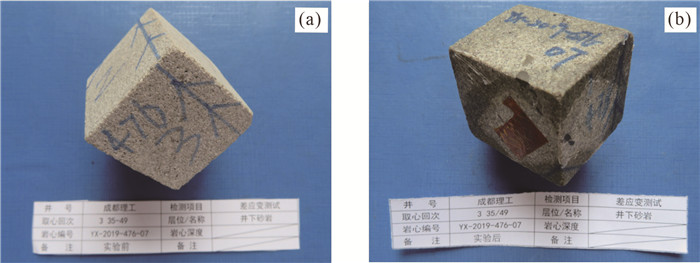

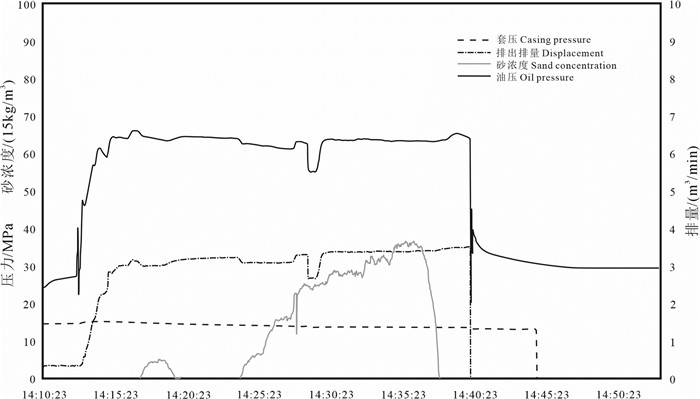

图 2 声发射实验结果图

a—HC137井须二1亚段2281.5 m样品声发射曲线;b—HC001-27-x1井须二2亚段2438.05 m样品声发射曲线;c—HC5井须二3亚段2231.1 m样品声发射曲线

Figure 2. Acoustic emission test results

a-Acoustic emission profile of a 2281.5 m sample from the first subsection of Xu-Ⅱ of well HC137; b-Acoustic emission profile of a 2438.05 m sample from the second subsection of Xu-Ⅱ of well HC001-27-x1; c-Acoustic emission profile of a 2231.1 m sample from the third subsection of Xu-Ⅱ of well HC5

图 3 须二段地应力大小统计图

a—四川盆地不同构造区须二段地应力大小统计图;b—HC001-69井须二段各小层样品地应力大小统计图

Figure 3. Statistical map of the magnitude of in-situ stress in the second member of Xujiahe Formation

a-Statistical map of the magnitude of in-situ stress in different tectonic zones of the Sichuan Basin in the second member of Xujiahe formation; b-Statistical map of the magnitude of in-situ stress in each sub-layer sample from the second member of Xujiahe Formation of well HC001-69

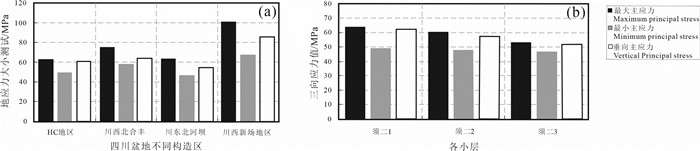

图 4 差应变实验中主应力比值随着围压变化曲线图,HC001-27-x1,2404.8 m

a—岩心9通道主应力比值随围压变化曲线;b—岩心主应力比值随围压变化曲线

Figure 4. Variation of principal stress ratio with surrounding pressure in differential strain experiments, HC001-27-x1, 2404.8 m

a-Variation of principal stress ratio with surrounding pressure for 9 channels in the core; b-Variation of core principal stress ratio with the surrounding pressure

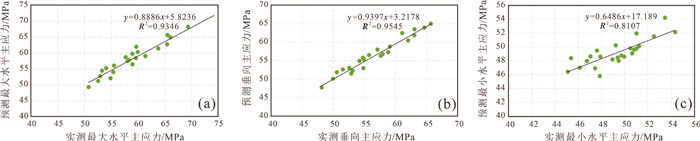

图 7 须二段各小层实测与测井计算应力值对比图

a—须二段各小层实测与测井计算最大水平主应力对比图;b—须二段各小层实测与测井计算垂向主应力对比图;c—须二段各小层实测与测井计算最小水平主应力对比图

Figure 7. Comparison of measured and logged stress values for each sub-layer in the second member of Xujiahe Formation

a-Comparison of measured and logged maximum horizontal principal stress in each sub-section of Xu-Ⅱ; b-Comparison of measured and logged vertical principal stress in each sub-section of Xu-Ⅱ; c-Comparison of measured and logged minimum horizontal principal stress in each subsection of Xu-Ⅱ

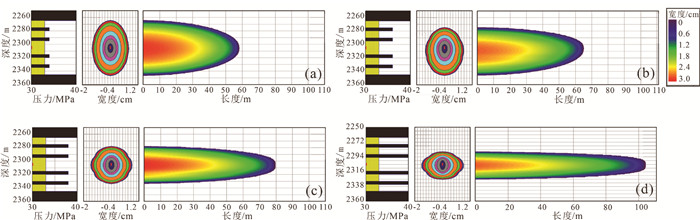

图 9 不同内部应力差模拟水力裂缝扩展形态图

50 MPa,隔层为51 MPa时裂缝扩展形态;b—储层应力为50 MPa,隔层为53 MPa时裂缝扩展形态;c—储层应力为50 MPa,隔层为55 MPa时裂缝扩展形态;d—储层应力为50 MPa,隔层为57 MPa时裂缝扩展形态

Figure 9. Simulation of hydraulic fracture extension patterns with different internal stress differences

a-Fracture extension pattern at 50 MPa for reservoir stress and 51 MPa for compartment; b-Fracture extension pattern at 50 MPa for reservoir stress and 53 MPa for compartment; c-Fracture extension pattern at 50 MPa for reservoir stress and 55 MPa for compartment; d-Fracture extension pattern at 50 MPa for reservoir stress and 57 MPa for compartment

图 10 不同内部应力隔层厚度模拟水力裂缝扩展形态图

a—隔层为1 m时裂缝形态;b—隔层为3 m时裂缝形态;c—隔层为5 m时裂缝形态; d—隔层为7 m时裂缝形态

Figure 10. Simulation of hydraulic fracture extension patterns with different internal stress compartment thicknesses

a-Crack pattern at a compartment thickness of 1 m; b-Crack pattern at a compartment thickness of 3 m; c-Crack pattern at a compartment thickness of 5 m; d-Crack pattern at a compartment thickness of 7 m

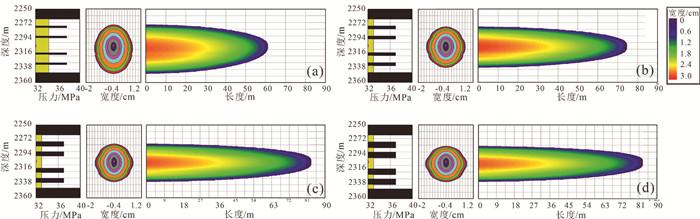

图 11 HC001-5-x3须二段压裂裂缝形态模拟图

a—HC001-5-x3须二1亚段压裂裂缝形态模拟图;b—HC001-5-x3须二2亚段压裂裂缝形态模拟图;c—HC001-5-x3须二3亚段压裂裂缝形态模拟图

Figure 11. Simulation of the fracture pattern of the second member of Xujiahe Formation fracture in well HC001-5-x3

a-Simulation of fracture morphology in the first subsection of Xu-Ⅱ of well HC001-5-x3; b—Simulation of fracture morphology in the second subsection of Xu-Ⅱ of well HC001-5-x3; c-Simulation of fracture morphology in the third subsection of Xu-Ⅱ of well HC001-5-x3

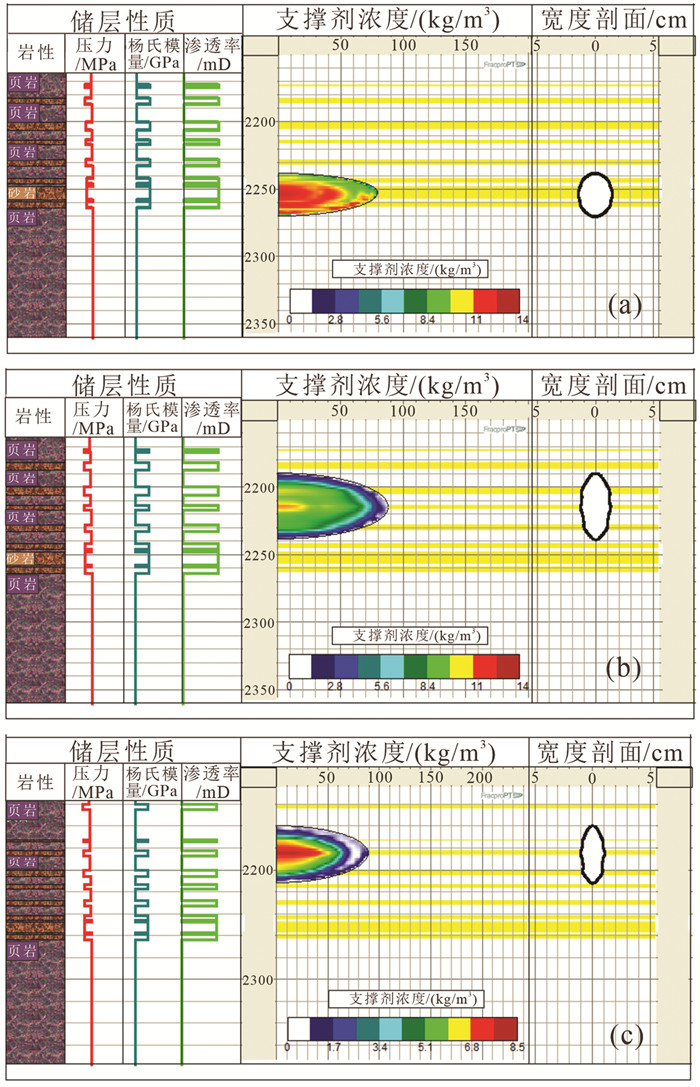

图 12 须二2亚段两向应力差异系数分布图

a—须二段沉积相图;b—须二2亚段两向应力差异系数三维分布图

Figure 12. Distribution of the differential coefficient of two-dimensional horizontal stress for the second subsection of Xu-Ⅱ

a—Sedimentary facies map of the second member of Xujiahe Formation; b—Three-dimensional distribution of the differential coefficient of horizontal in-situ stress in both directions for the second subsection of Xu-Ⅱ

表 1 HC地区须家河组声发射实验测试的三向应力值的测试结果数据表(部分)

Table 1 Results of three-dimensional stress values of the second member of Xujiahe Formation in HC area by acoustic emission test

表 2 HC地区须二段差应变实验测试的三向应力值的测试

Table 2 Results of three-dimensional stress values of the second member of Xujiahe Formation in HC area by differential strain test

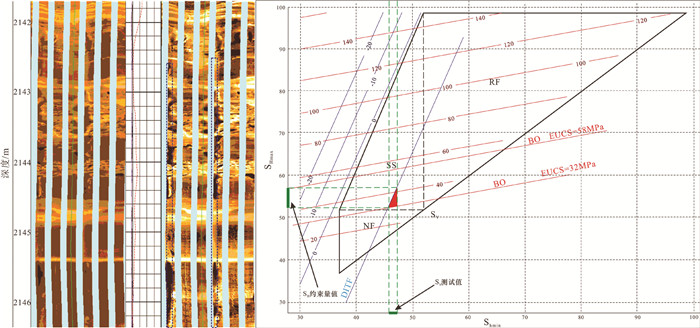

表 3 水压致裂法计算的地应力大小的数据结果

Table 3 Results of the magnitude of in-situ stress calculated using hydraulic fracturing

-

Cai Meifeng. 1993. Review of principles and methods for rock stress measurement[J]. Chinese Journal of Rock Mechanics and Engineering, 12(3): 275-283 (in Chinese with English abstract).

Cao Hui, Sun Dongsheng, Yuan Kun, Li Awei, Zhang Guanghan. 2020. In-situ stress determination of 3 km oil-gas deep hole and analysis of the tectonic stress field in the southern Guizhou[J]. Geology in China, 47(1): 88-98 (in Chinese with English abstract).

Chen Nian, Wang Chenghu, Gao Guiyun, Wang Pu. 2021. Characteristics of in-situ stress field in the powerhouse area on the right bank of Baihetan based on stress polygon and borehole breakout method[J]. Rock and Soil Mechanics, 42(12): 3376-3384 (in Chinese with English abstract).

Ding Wenlong, Wang Xinghua, Hu Qiujia, Yin Shuai, Cao Xiangyu, Liu Jianjun. 2015. Progress in tight sandstone reservoir fractures research[J]. Advances in Earth Science, 30(7): 737-750 (in Chinese with English abstract).

Fraser D, Gholami R, Sarmadivaleh M. 2021. Deformation rate analysis: How to determine in-situ stresses in unconventional gas reservoirs[J]. International Journal of Rock Mechanics and Mining Sciences, 146(7/8): 104892.

Guo Weijie, Gong Cheng, Li Jing. 2010. The measurements of geostress and the problems of geo-stress measurement[J]. Value Engineering, 29(25): 136-137 (in Chinese with English abstract). doi: 10.3969/j.issn.1006-4311.2010.25.095

Han Jun, Liu Hongtao. 2005. Application of differential strain analysis method on the study of in-situ stress direction[J]. Journal of Oil and Gas Technology, 27(2): 87-88, 95, 8(in Chinese with English abstract).

He Xiaodong, Ma Junxiu, Shi Shanzhi, Liu Gang, Tan Qiang. 2020. Core differential strain test of tight glutinite reservoir in Mahu oilfield[J]. China Offshore Oil and Gas, 32(3): 86-93 (in Chinese with English abstract).

Jayanthu S. 2019. Estimation of in-situ stress-experiemtnal trials on Kaiser effect and hydrofracturing tests[J]. Journal of Mines, Metals and Fuels, 67(6): 311-315.

Ji Zhijiu, Lu Guobin, Li Lan, 2009. Study on in-situ stress measurement method and engineering application[J]. Modern Mining, 25(11): 67-69 (in Chinese with English abstract). doi: 10.3969/j.issn.1674-6082.2009.11.020

Jiang Yongdong, Xian Xuefu, Xu Jiang. 2005. Research on application of Kaiser effect of acoustic emission to measuring initial stress in rock mass[J]. Rock and Soil Mechanics, 26(6): 946-950 (in Chinese with English abstract). doi: 10.3969/j.issn.1000-7598.2005.06.025

Jing Feng, Liang Hecheng, Bian Zhihua, Liu Yuankun. 2008. Review of geo-stress measurement method and study[J]. Journal of North China University of Water Resources and Electric Power(Natural Science Edition), 29(2): 71-75 (in Chinese with English abstract). doi: 10.3969/j.issn.1002-5634.2008.02.023

Lehtonen A, Cosgrove J W, Hudson J A, Johansson E. 2011. An examination of in situ rock stress estimation using the Kaiser effect[J]. Engineering Geology, 124: 24-37 doi: 10.3969/j.issn.1000-3665.2011.03.005

Li Guohui, Li Nan, Xie Jirong, Yang Jiajing, Tang Dahai. 2012. Basic features of large gas play fairways in the upper Triassic Xujiahe Formation of the Sichuan Foreland Basin and evaluation of favorable exploration zones[J]. Natural Gas Industry, 32(3): 15-21, 122-123 (in Chinese with English abstract). doi: 10.3787/j.issn.1000-0976.2012.03.003

Liang Chen. 2020. Theory and Numerical Analysis of a New Method of In-Situ Stress Measurement[D]. Wuhan: Hubei University of Technology (in Chinese with English abstract).

Liu R, Hao F, Engelder T, Shu Z, Yi J, Xu S, Teng C. 2019. Stress memory extracted from shale in the vicinity of a fault zone: Implications for shale-gas retention[J]. Marine and Petroleum Geology, 102: 340-349. doi: 10.1016/j.marpetgeo.2018.12.047

Liu Yaqun, Li Haibo, Jing Feng, Luo Chaowen, Chen Bingrui, Li Junru, Zhou Qingqing. 2007. Determination of in-situ stress by hydraulic fracturing tests on preexisting fractures considering stress gradient and its engineering application[J]. Chinese Journal of Rock Mechanics and Engineering, 26(6): 1145-1149 (in Chinese with English abstract). doi: 10.3321/j.issn:1000-6915.2007.06.007

Liu Zekai, Chen Yaolin, Tang Ruzhong. 1994. Application of in-situ stress technology in oilfield development[J]. Petroleum Geology and Recovery Efficiency, 1(1): 48-56, 85(in Chinese).

Ma Rui. 2014. Application of ground stress in oil and gas exploration and development[J]. Science & Technology Information, 12(31): 55-58(in Chinese).

Mao H, Luo T, Lai F, Zhang G, Zhong L. 2019. Experimental analysis and logging evaluation of in-situ stress of mud shale reservoir——Taking the deep shale gas reservoir of Longmaxi Formation in western Chongqing as an example[C]//IOP Conference Series: Earth and Environmental Science, 384: 012129.

Mayerhofer M J, Lolon E P, Warpinski N R, Cipolla C L, Walser D, Rightmire C M. 2010. What is stimulated reservoir volume?[J]. SPE Production & Operations, 25(1): 89-98.

Nie Zhou. 2018. Study on the Reservoir Characteristics of the Second Member of Xujiahe Formation in the Central Sichuan Area[D]. Chengdu: Chengdu University of Technology (in Chinese with English abstract).

Ning Wenxiang, He Bai, Li Fengxia, Xie Lingzhi, Shi Aiping, He Qiang. 2021. Experimental study on fractures morphology of hydraulic fracturing in continental shale oil reservoir[J] Science Technology and Engineering, 21(18): 7505-7512 (in Chinese with English abstract). doi: 10.3969/j.issn.1671-1815.2021.18.015

Renshaw C E, Pollard D D. 1994. Are large differential stresses required for straight fracture propagation paths?[J]. Journal of Structural Geology, 16(6): 817-822. doi: 10.1016/0191-8141(94)90147-3

Schmitt D R, Currie C A, Zhang L. 2012. Crustal stress determination from boreholes and rock cores: Fundamental principles[J]. Tectonophysics, 580: 1-26. doi: 10.1016/j.tecto.2012.08.029

Shen Haichao, Cheng Yuanfang, Wang Jingyin, Zhao Yizhong, Zhang Jianguo. 2008. Principal direction differential strain method for in-situ stress measurement and application[J]. Xinjiang Petroleum Geology, 29(2): 250-252 (in Chinese with English abstract).

Shi Can, Lin Botao. 2021. Principles and influencing factors for shale formations[J]. Petroleum Science Bulletin, 6(1): 92-113 (in Chinese with English abstract).

Wang Chenghu, Gao Guiyun, Wang Hong, Wang Pu. 2020. Integrated determination of principal stress and tensile strength of rock based on the laboratory and field hydraulic fracturing tests[J]. Journal of Geomechanics, 26 (2): 167-174 (in Chinese with English abstract).

Wang Chenghu. 2014. Brief review and outlook of main estimate and measurement methods for in situ stresses in rock mass[J]. Geological Review, 60(5): 971-991, 996, 992-995 (in Chinese with English abstract).

Wang Hongwei. 2007. Study On Comprehensive Interpretation Method of Earth Stress In Different Tracts In Hailaer Oilfield[D]. Daqing: Daqing Petrolum Institute(in Chinese with English abstract).

Wang Pu, Wang Chenghu, Yang Ruhua, Hou Zhengyang, Wang Hong. 2019. Preliminary investigation on the deep rock stresses prediction method based on stress polygon and focal mechanism solution[J]. Rock and Soil Mechanics, 40(11): 4486-4496 (in Chinese with English abstract).

Wang S, Han F, Bing Q. 2021. Application of In-situ Stress Calculation in Engineering[C]//IOP Conference Series: Earth and Environmental Science, 660(1): 012040.

Zeng Zhiping, Liu Zhen, Ma Ji, Zhang Chunlei, Li Jing, Liu Zhen, Sun Luning. 2019. A new method for fracrability evaluation in deep and tight sandstone reservoirs[J]. Journal of Geomechanics, 25(2): 223-232 (in Chinese with English abstract).

Zhang R, Hou B, Han H, Fan M, Chen M. 2019. Experimental investigation on fracture morphology in laminated shale formation by hydraulic fracturing[J]. Journal of Petroleum Science and Engineering, 177: 442-451. doi: 10.1016/j.petrol.2019.02.056

Zhang Zhongyuan, Wu Manlu, Chen Qunce, Liao Chunting, Feng Chengjun. 2012. Review of in-situ stress measurement methods[J]. Journal of Henan Polytechnic University (Natural Science), 31(3): 305-310 (in Chinese with English abstract).

Zhao Gang, Dong Shier. 2009. The theory of the measurement of ground stress by hydraulic fracturing method and its application[J]. Shanxi Architecture, 35(36): 77-78 (in Chinese with English abstract). doi: 10.3969/j.issn.1009-6825.2009.36.048

Zhao Jinghui, Gao Yuqiao, Chen Zhenlong, Guo Tao, Gao Xiaokang. 2021. Stress state of deep seam and its influence on development performance of CBM wells in South Yanchuan Block, Odors Basin[J]. Geology in China, 48(3): 785-793 (in Chinese with English abstract).

Zhao Jinzhou, Li Yongming, Wang Song, Jiang Youshi, Zhang Liehui. 2014. Simulation of a complex fracture network influenced by natural fractures[J]. Natural Gas Industry, 34(1): 68-73 (in Chinese with English abstract). doi: 10.3787/j.issn.1000-0976.2014.01.010

Zhao Yajun, Meng Nannan. 2015. Review of in-situ stress measurement methods[J]. Inner Mongolia Coal Economy, (5): 209-210(in Chinese). doi: 10.3969/j.issn.1008-0155.2015.05.126

Zhao Zhengwang, Li Nan, Liu Min, Wang Xiaojuan, Wu Changjiang, Li Li. 2019. Origin of gas accumulation and high yield in tight gas reservoirs of Xujiahe Formation, Sichuan Basin[J]. Natural Gas Exploration and Development, 42(2): 39-47 (in Chinese with English abstract).

Zheng Herong, Liu Zhongqun, Xu Shilin, Liu Zhenfeng, Liu Junlong, Huang Zhiwen, Huang Yanqing, Shi Zhiliang, Wu Qingzhao, Fan Lingxiao, Gao Jinhui. 2021. Progress and key research directions of tight gas exploration and development in Xujiahe Formation, Sinopec exploration areas, Sichuan Basin[J]. Oil & Gas Geology, 42(4): 765-783 (in Chinese with English abstract).

Zhu Hongquan, Zhang Zhuang, Nan Hongli, Ye Sujuan, Zhang Shihua, Wang Linghui. 2019. Reservoir formation and enrichment rules and exploration practices in overlying dense sandstone gas zones[J]. Natural Gas Industry, 39(S1): 9-16 (in Chinese).

蔡美峰. 1993. 地应力测量原理和方法的评述[J]. 岩石力学与工程学报, 12(3): 275-283. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX199303009.htm 曹慧, 孙东生, 苑坤, 李阿伟, 张光晗. 2020. 黔南地区~3 km油气深孔地应力测量与构造应力场分析[J]. 中国地质, 47(1): 88-98. http://geochina.cgs.gov.cn/geochina/article/abstract/20200107?st=search 陈念, 王成虎, 高桂云, 王璞. 2021. 基于应力多边形与钻孔崩落的白鹤滩右岸厂房区地应力场特征研究[J]. 岩土力学, 42(12): 3376-3384. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202112017.htm 丁文龙, 王兴华, 胡秋嘉, 尹帅, 曹翔宇, 刘建军. 2015. 致密砂岩储层裂缝研究进展[J]. 地球科学进展, 30(7): 737-750. https://www.cnki.com.cn/Article/CJFDTOTAL-DXJZ201507001.htm 郭伟杰, 龚成, 李晶. 2010. 地应力测量方法及其需要注意的问题[J]. 价值工程, 29(25): 136-137. https://www.cnki.com.cn/Article/CJFDTOTAL-JZGC201025098.htm 韩军, 刘洪涛. 2005. 差应变分析法在地应力方向研究中的应用[J]. 石油天然气学报(江汉石油学院学报), 27(2): 87-88, 95, 8. https://www.cnki.com.cn/Article/CJFDTOTAL-JHSX2005S2023.htm 何小东, 马俊修, 石善志, 刘刚, 谭强. 2020. 玛湖油田致密砂砾岩储层岩心差应变实验[J]. 中国海上油气, 32(3): 86-93. https://www.cnki.com.cn/Article/CJFDTOTAL-ZHSD202003010.htm 纪志久, 卢国斌, 李岚. 2009. 地应力测量方法及工程应用研究[J]. 现代矿业, 25(11): 67-69. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB200911025.htm 姜永东, 鲜学福, 许江. 2005. 岩石声发射Kaiser效应应用于地应力测试的研究[J]. 岩土力学, 26(6): 946-950. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200506027.htm 景锋, 梁合成, 边智华, 刘元坤. 2008. 地应力测量方法研究综述[J]. 华北水利水电学院学报, 29(2): 71-75. https://www.cnki.com.cn/Article/CJFDTOTAL-HBSL200802022.htm 李国辉, 李楠, 谢继容, 杨家静, 唐大海. 2012. 四川盆地上三叠统须家河组前陆大气区基本特征及勘探有利区[J]. 天然气工业, 32(3): 15-21, 122-123. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201203004.htm 梁晨. 2020. 一种新的地应力测量方法理论及数值分析[D]. 武汉: 湖北工业大学. 刘亚群, 李海波, 景锋, 罗超文, 陈炳瑞, 李俊如, 周青春. 2007. 考虑应力梯度的原生裂隙水压致裂法地应力测量的原理及工程应用[J]. 岩石力学与工程学报, 26(6): 1145-1149. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200706007.htm 刘泽凯, 陈耀林, 唐汝众. 1994. 地应力技术在油田开发中的应用[J]. 油气采收率技术, 1(1): 48-56, 85. https://www.cnki.com.cn/Article/CJFDTOTAL-YQCS401.008.htm 马睿. 2014. 地应力在油气勘探开发中的应用[J]. 科技资讯, 12(31): 55-58. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXLJ201431042.htm 聂舟. 2018. 川中地区须家河组二段储层特征研究[D]. 成都: 成都理工大学, 1-4. 宁文祥, 何柏, 李凤霞, 谢凌志, 史爱萍, 何强. 2021. 陆相页岩油储层水力压裂裂缝形态的试验[J]. 科学技术与工程, 21(18): 7505-7512. https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202118015.htm 沈海超, 程远方, 王京印, 赵益忠, 张建国. 2008. 主方向差应变地应力测量方法[J]. 新疆石油地质, 29(2): 250-252. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD200802042.htm 史璨, 林伯韬. 2021. 页岩储层压裂裂缝扩展规律及影响因素研究探讨[J]. 石油科学通报, 6(1): 92-113. https://www.cnki.com.cn/Article/CJFDTOTAL-SYKE202101008.htm 王成虎. 2014. 地应力主要测试和估算方法回顾与展望[J]. 地质论评, 60(5): 971-991, 996, 992-995. https://www.cnki.com.cn/Article/CJFDTOTAL-DZLP201405003.htm 王成虎, 高桂云, 王洪, 王璞. 2020. 利用室内和现场水压致裂试验联合确定地应力与岩石抗拉强度[J]. 地质力学学报, 26(2): 167-174. https://www.cnki.com.cn/Article/CJFDTOTAL-DZLX202002002.htm 王宏伟. 2007. 海拉尔油田不同区块地应力综合解释方法研究[D]. 大庆: 大庆石油学院, 1-5. 王璞, 王成虎, 杨汝华, 侯正阳, 王洪. 2019. 基于应力多边形与震源机制解的深部岩体应力状态预测方法初探[J]. 岩土力学, 40(11): 4486-4496. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201911040.htm 曾治平, 刘震, 马骥, 张春磊, 李静, 刘振, 孙鲁宁. 2019. 深层致密砂岩储层可压裂性评价新方法[J]. 地质力学学报, 25(2): 223-232. https://www.cnki.com.cn/Article/CJFDTOTAL-DZLX201902008.htm 张重远, 吴满路, 陈群策, 廖椿庭, 丰成君. 2012. 地应力测量方法综述[J]. 河南理工大学学报(自然科学版), 31(3): 305-310. https://www.cnki.com.cn/Article/CJFDTOTAL-JGXB201203010.htm 赵刚, 董事尔. 2009. 水压致裂法测量地应力理论与应用[J]. 山西建筑, 35(36): 77-78. https://www.cnki.com.cn/Article/CJFDTOTAL-JZSX200936047.htm 赵景辉, 高玉巧, 陈贞龙, 郭涛, 高小康. 2021. 鄂尔多斯盆地延川南区块深部地应力状态及其对煤层气开发效果的影响[J]. 中国地质, 48(3): 785-793. http://geochina.cgs.gov.cn/geochina/article/abstract/20210309?st=search 赵金洲, 李勇明, 王松, 江有适, 张烈辉. 2014. 天然裂缝影响下的复杂压裂裂缝网络模拟[J]. 天然气工业, 34(1): 68-73. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201401013.htm 赵亚军, 孟楠楠. 2015. 地应力测量方法综述[J]. 内蒙古煤炭经济, (5): 209-210. https://www.cnki.com.cn/Article/CJFDTOTAL-LMMT201505126.htm 赵正望, 李楠, 刘敏, 王小娟, 吴长江, 李莉. 2019. 四川盆地须家河组致密气藏天然气富集高产成因[J]. 天然气勘探与开发, 42(2): 39-47. https://www.cnki.com.cn/Article/CJFDTOTAL-TRKT201902009.htm 郑和荣, 刘忠群, 徐士林, 刘振峰, 刘君龙, 黄志文, 黄彦庆, 石志良, 武清钊, 范凌霄, 高金慧. 2021. 四川盆地中国石化探区须家河组致密砂岩气勘探开发进展与攻关方向[J]. 石油与天然气地质, 42(4): 765-783. https://www.cnki.com.cn/Article/CJFDTOTAL-SYYT202104002.htm 朱宏权, 张庄, 南红丽, 叶素娟, 张世华, 王玲辉. 2019. 叠覆型致密砂岩气区成藏富集规律与勘探实践[J]. 天然气工业, 39(S1): 9-16. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG2019S1003.htm -

期刊类型引用(9)

1. 金爱芳,殷秀兰,李长青,李文娟,庞菊梅,金晓媚. 张家口地区枯水期地下水水化学特征及其成因机制分析. 环境科学. 2024(02): 826-836 .  百度学术

百度学术

2. 孟瑞芳,杨会峰,包锡麟,徐步云,李磊,李谨丞. 京津冀平原非常规水资源利用前景分析及其生态环境效应. 中国地质. 2024(01): 221-233 .  本站查看

本站查看

3. 李晓波,李静. 大汶河流域中下游浅层地下水水化学特征及其影响因素. 环境科学研究. 2024(05): 1015-1026 .  百度学术

百度学术

4. 唐辉,何欣琳,郭晓静,马兴瑾,朱家葆. 郑州市城区浅层地下水环境化学特征及成因分析. 河南科学. 2024(08): 1192-1201 .  百度学术

百度学术

5. 刘春燕,刘景涛,朱亮,张玉玺,荆继红,黄冠星,周冰,陈玺,解飞,李备. 高原河谷城市浅层地下水铁锰分布特征、影响因素及其对生态环境的影响——以西宁市为例. 中国地质. 2024(05): 1776-1790 .  本站查看

本站查看

6. 张博深,李海明,苏思慧,李梦娣,张翠霞. 天津平原地下水水化学特征与碳酸盐风化碳汇特征的时空演变. 南水北调与水利科技(中英文). 2024(05): 1016-1028 .  百度学术

百度学术

7. Jing-jie Li,Sheng Lian,Ming-guo Wang,Huai-sheng Zhang,Tao Yang. Hydrochemical characteristics of surface water in Hengduan mountain region of Eastern Tibet and its response to human activities: A case study of Duoqu Basin, Jinsha River. China Geology. 2024(04): 630-641 .  必应学术

必应学术

8. 邹银先,褚学伟,刘埔,段先前,王中美,王益伟. 贵州喀斯特山区地下水化学特征分析. 地质与资源. 2024(06): 846-854+860 .  百度学术

百度学术

9. 李月,李洋,周盈,黄晓燕. 苏锡常地区深层地下水化学特征及成因探讨. 上海国土资源. 2024(04): 171-178+202 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: