Evaluation of in−situ stress orientations and rotational mechanical mechanisms in deep shale reservoirs: A case study of the Longmaxi Formation's first member and Wufeng Formation in the Yongchuan shale gas field, southern Sichuan Basin

-

摘要:研究目的

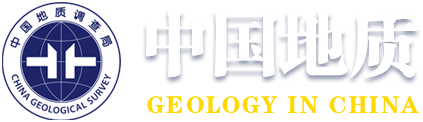

川南深层页岩储层五峰组—龙马溪组现今地应力方向变化复杂,且局部构造对地应力方向的影响尚不清晰。

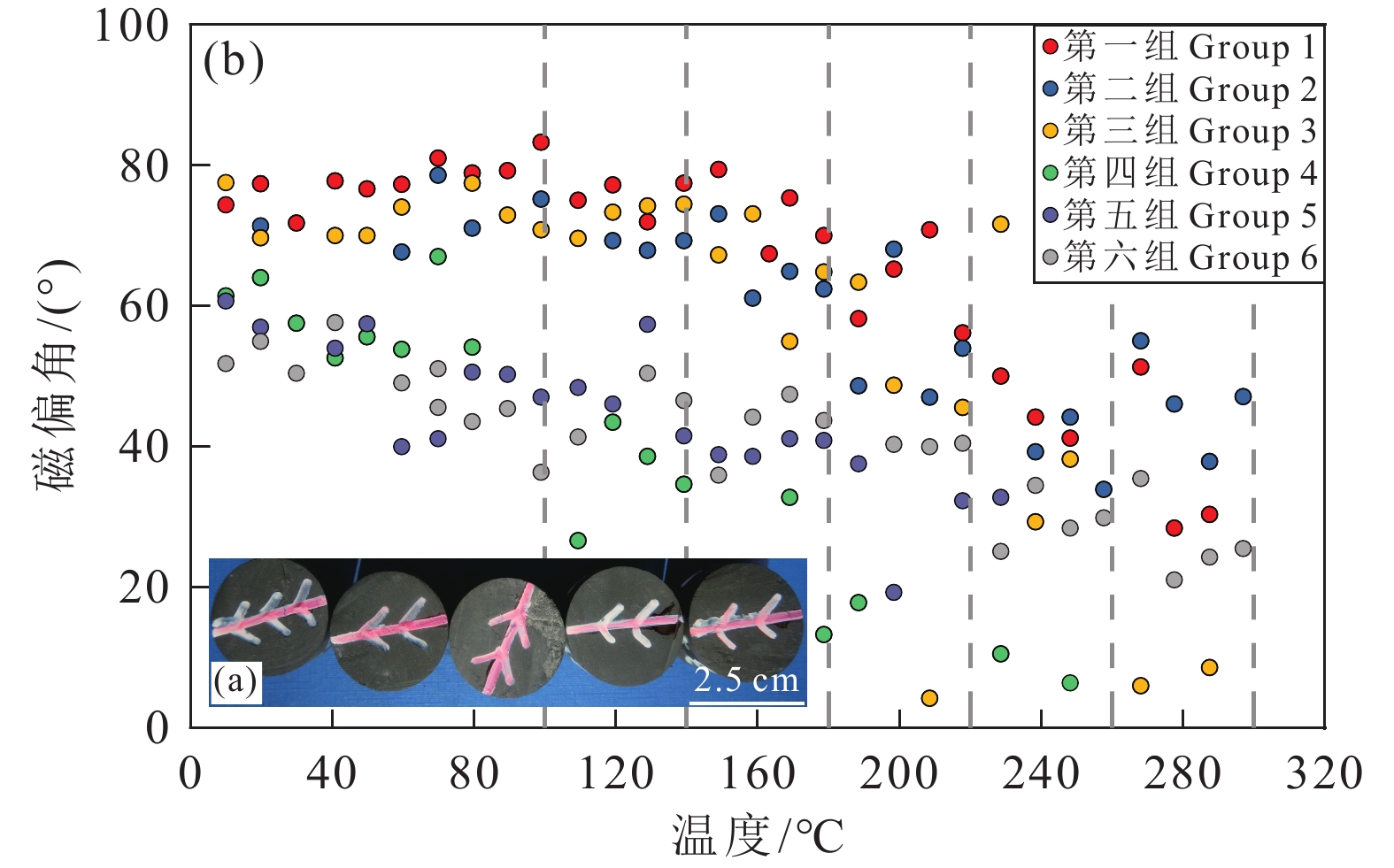

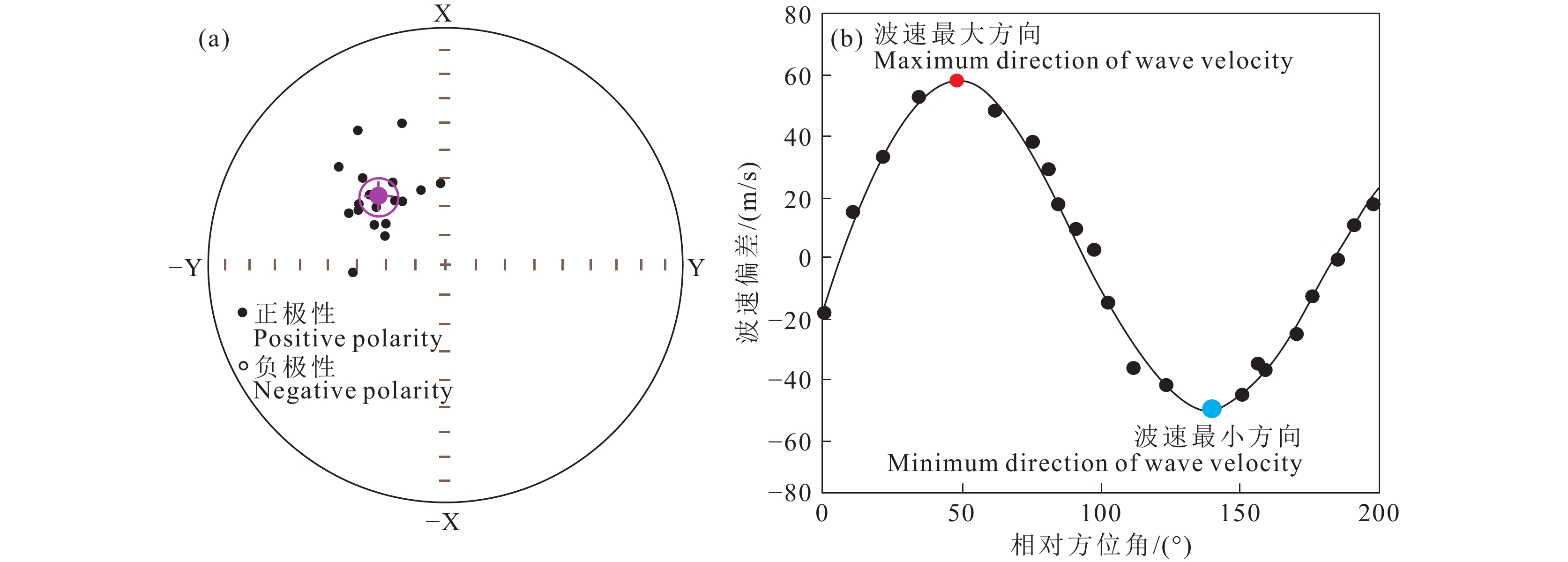

研究方法以川南永川页岩气区块为例,基于古地磁和波速各向异性实验,结合测井、微地震监测以及数值模拟手段评价了应力方向的分布特征及构造变形影响下的偏转。

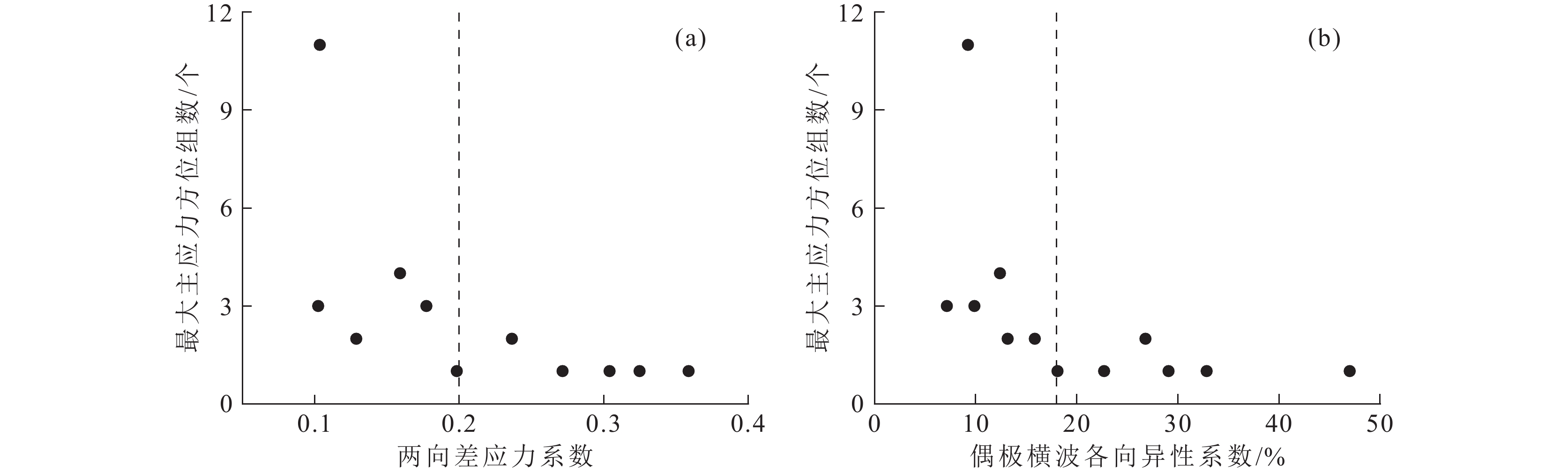

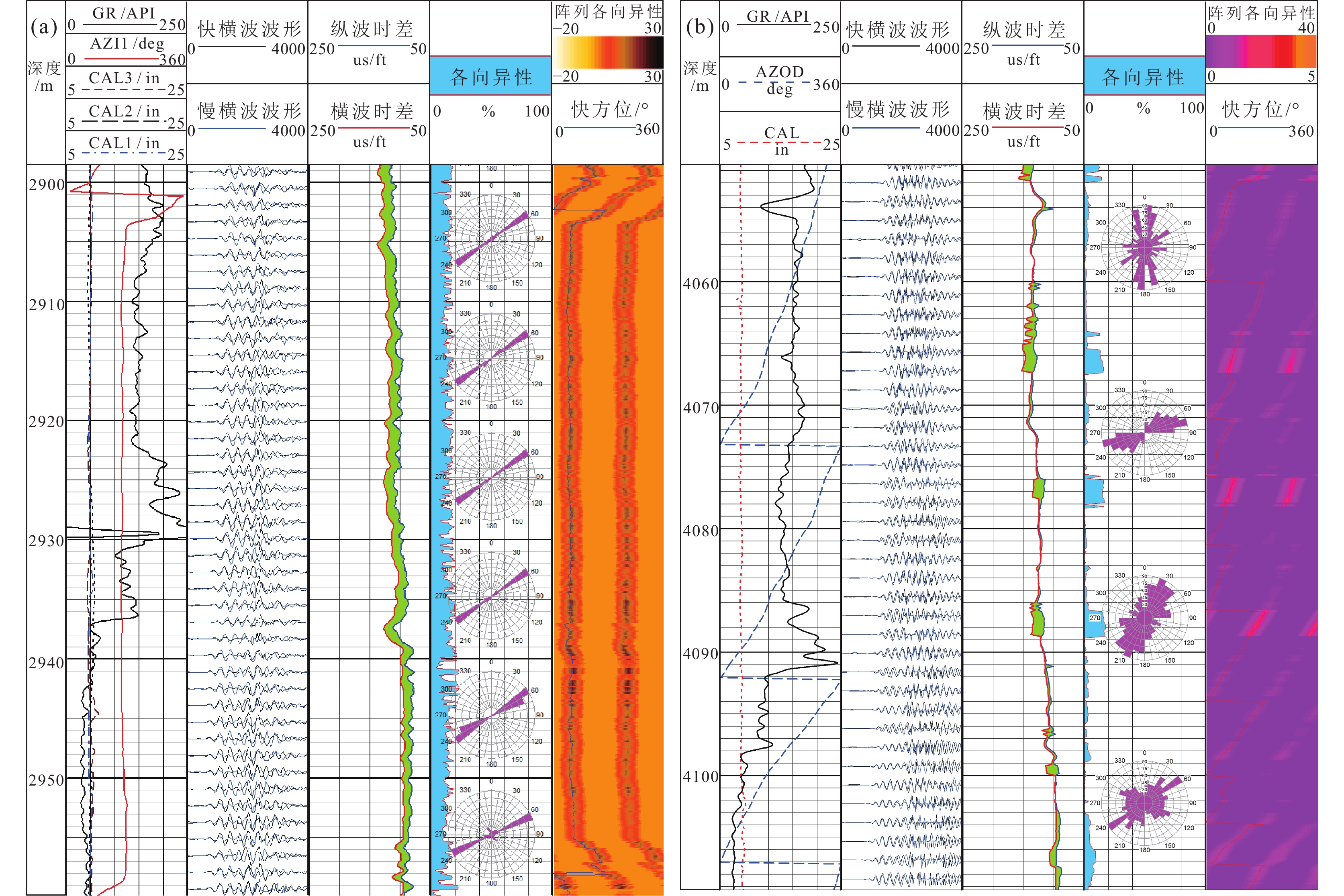

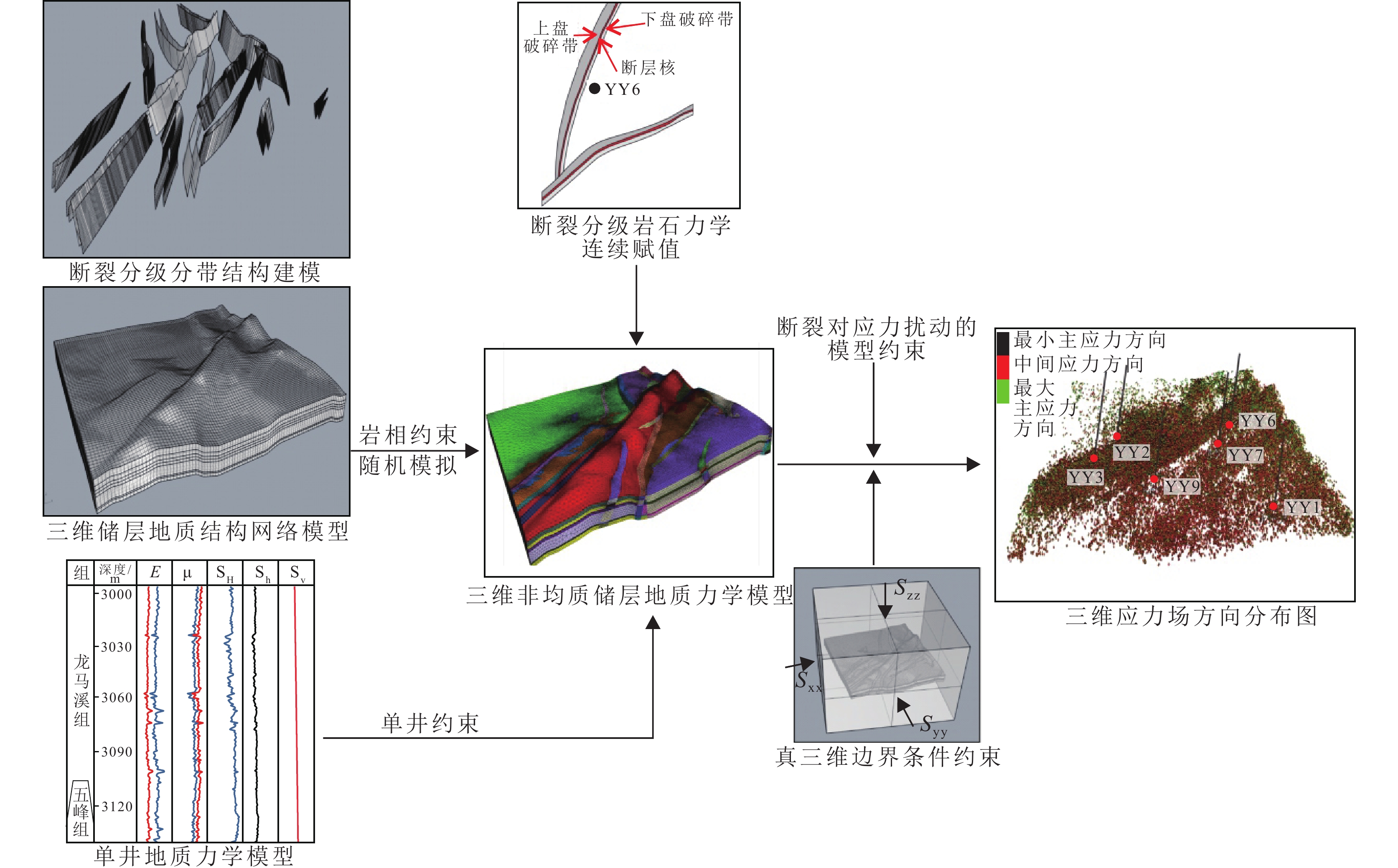

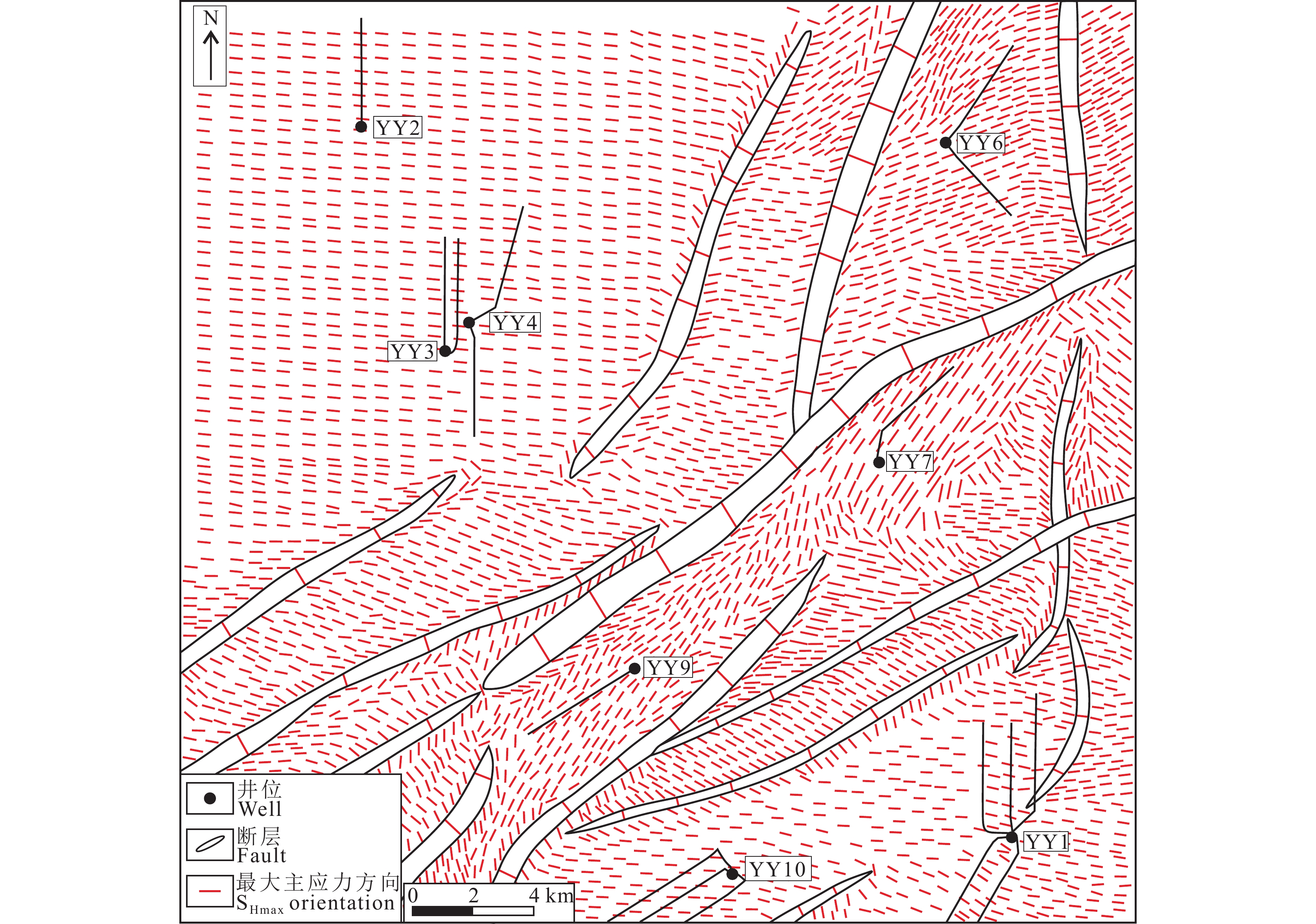

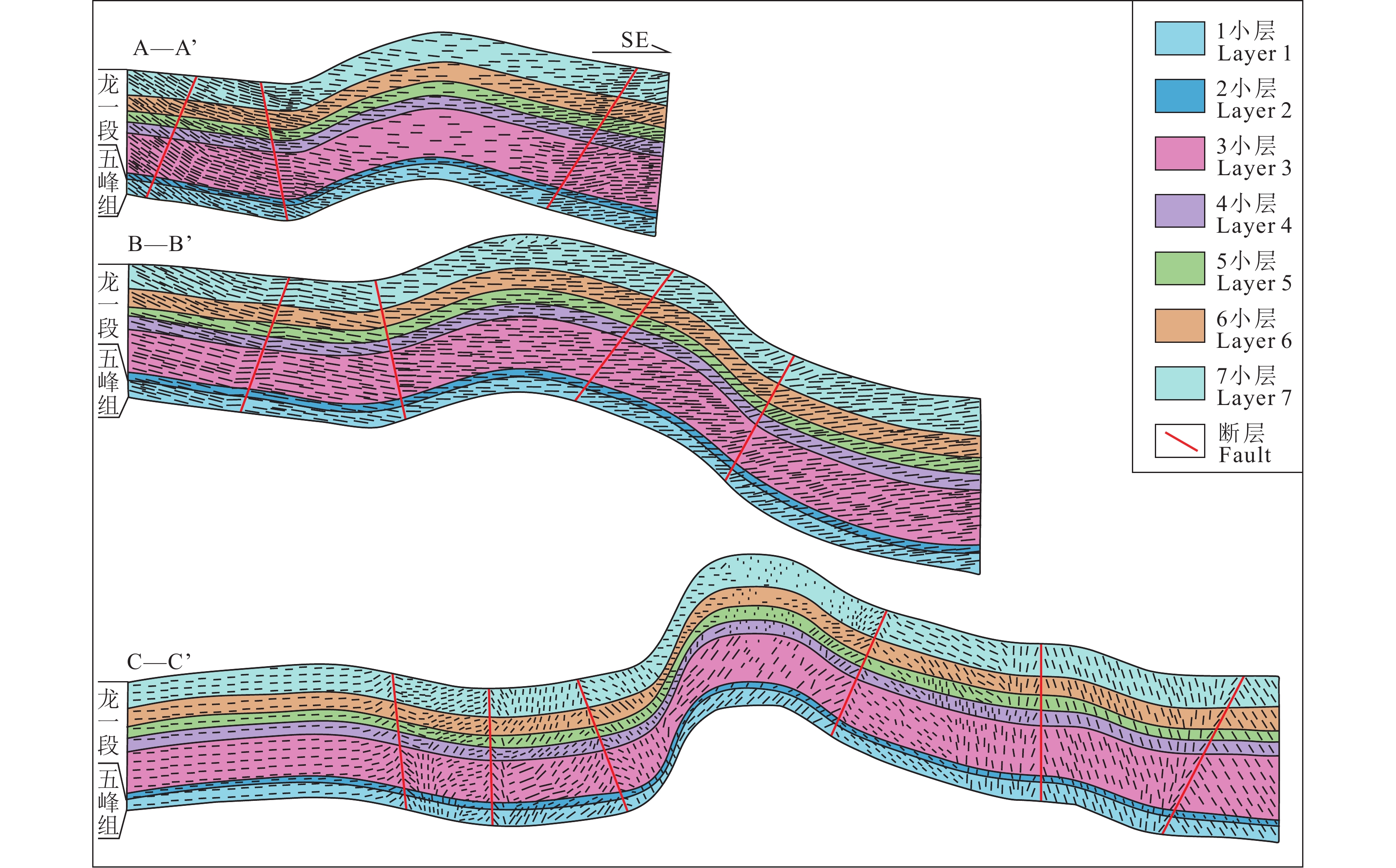

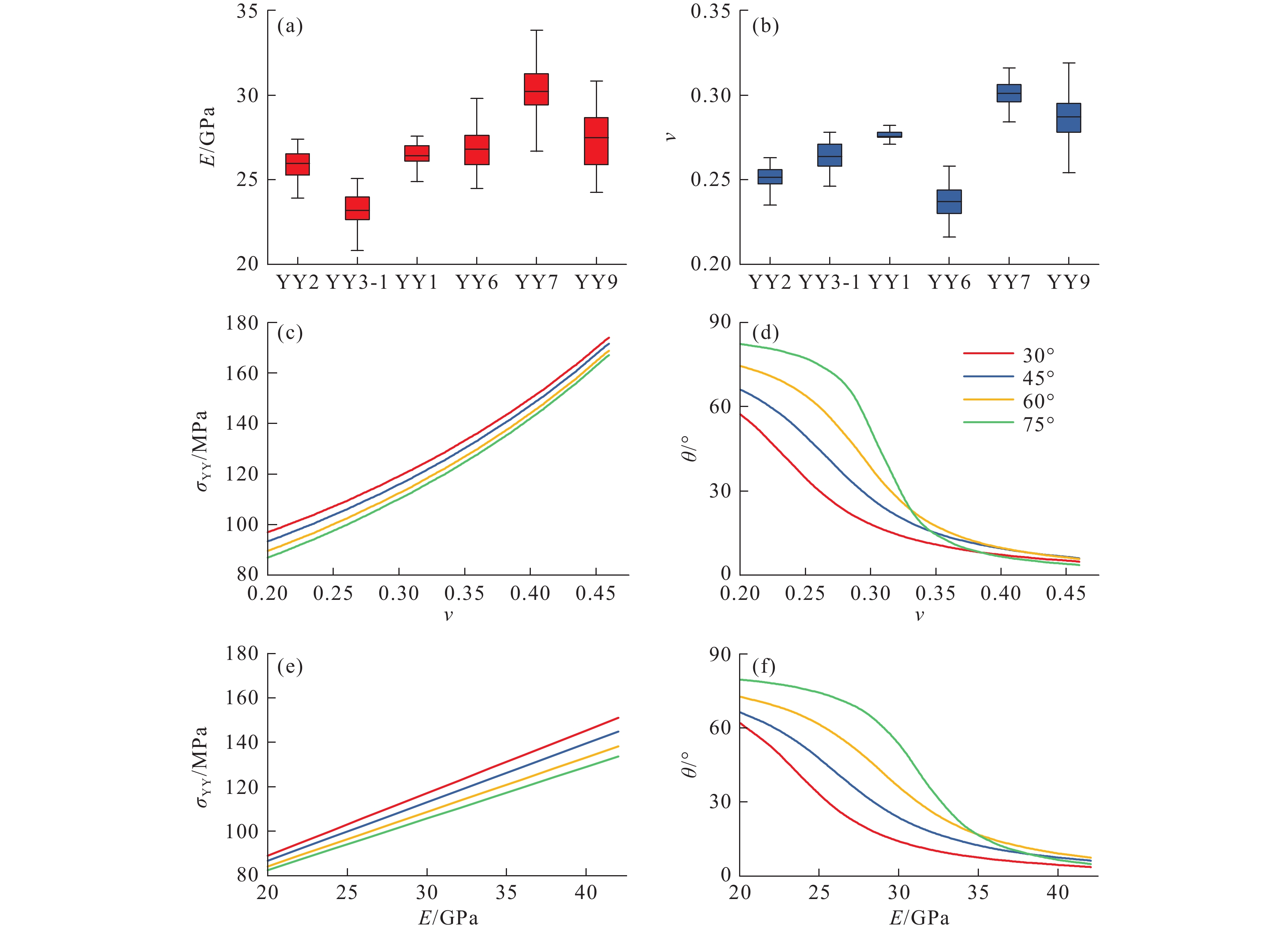

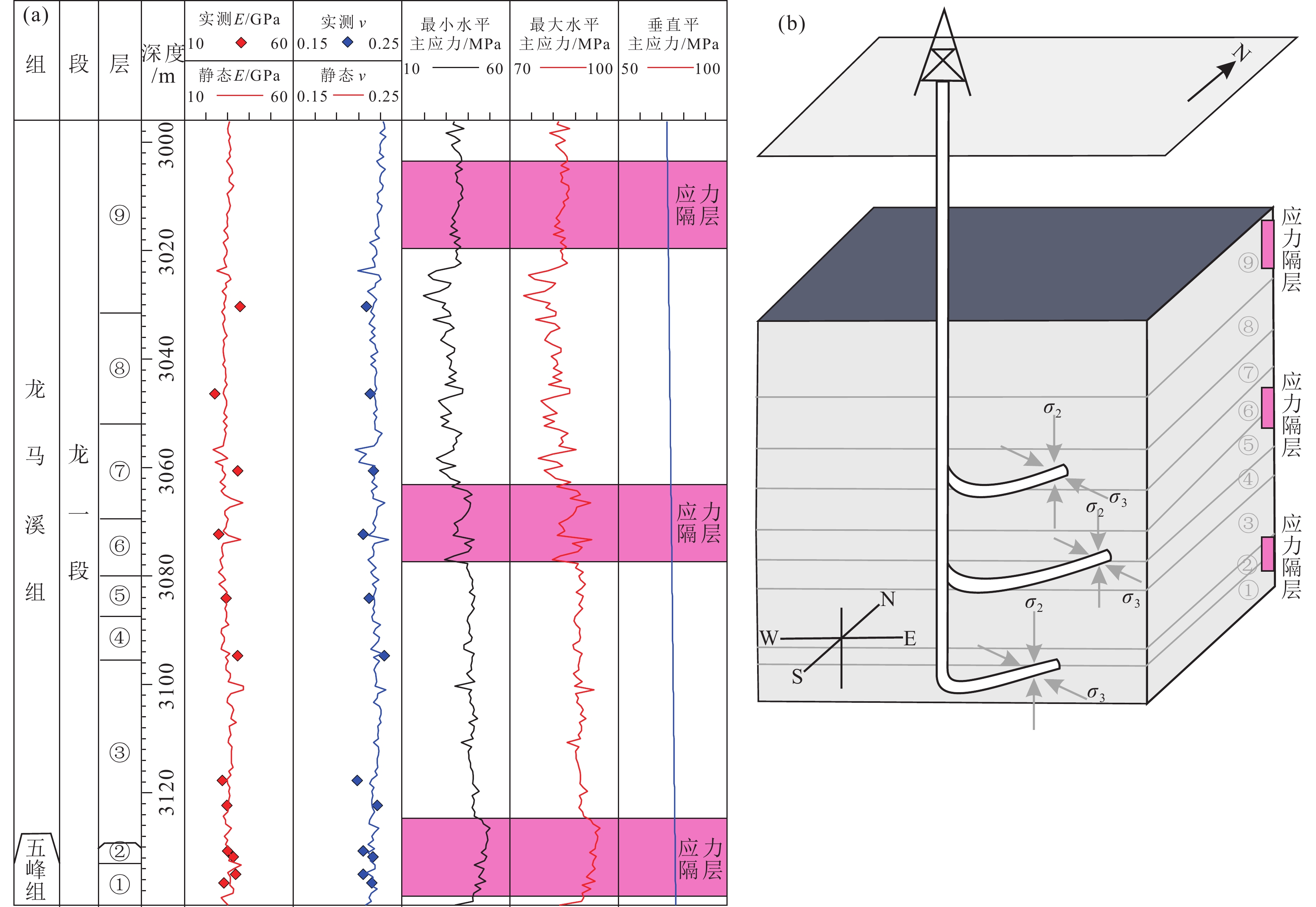

研究结果当应力差异系数大于0.2,横波各向异性系数大于18%时,偶极横波测井解释的准确度显著提高;在高陡地层(>60°),需同时考虑两向差应力和高角度裂缝发育情况对现今地应力方向解释的影响。永川向斜区最大主应力方向分布为近EW向,背斜核部及断块区方向发生了较大方向的偏移(方向偏差最大为70°±5°)。永川地区五峰组—龙马溪组中和面应位于龙一段1~2小层,中和面上下地应力方向变化呈相反趋势,褶皱派生应力介于10~30 MPa,对区域应力的影响不可忽略;随着距断层距离的减少,泊松比(ν)呈增大趋势并使得最大主应力方向偏转。

结论最大主应力方向有利于向斜区页岩气的保存,而背斜区的高角度天然裂缝则更易转变为有效裂缝。建议向斜区水平井部署方位为SN−NEE向;背斜区和夹持断块区以NE向为主且采用分层布井。

创新点:通过“岩心测试−井筒结构恢复−井旁波速各向异性提取−井间微地震监测−井区地质力学模拟”多源确定地应力方向,并建立了不同地质构造背景下页岩储层现今地应力方向的判定方法优选组合;明确了断层和褶皱对地应力方向扰动;分析了现今地应力方向对页岩气保存和开发的影响。

Abstract:This paper is the result of oil and gas exploration engineering.

ObjectiveThe present−day in−situ stress orientations within deep shale reservoirs of the Wufeng–Longmaxi Formation in the southern Sichuan Basin are intricate and have not been comprehensively evaluated. Moreover, the mechanisms through which local structures influence these stress orientations remain poorly understood.

MethodsThe Yongchuan shale gas field was selected as the study area to systematically investigate the characteristics and controlling factors of in−situ stress orientations. This evaluation employed a multi−faceted approach that included paleomagnetic analysis, seismic wave velocity anisotropy measurements, specialized well logging techniques, microseismic monitoring, and numerical simulations.

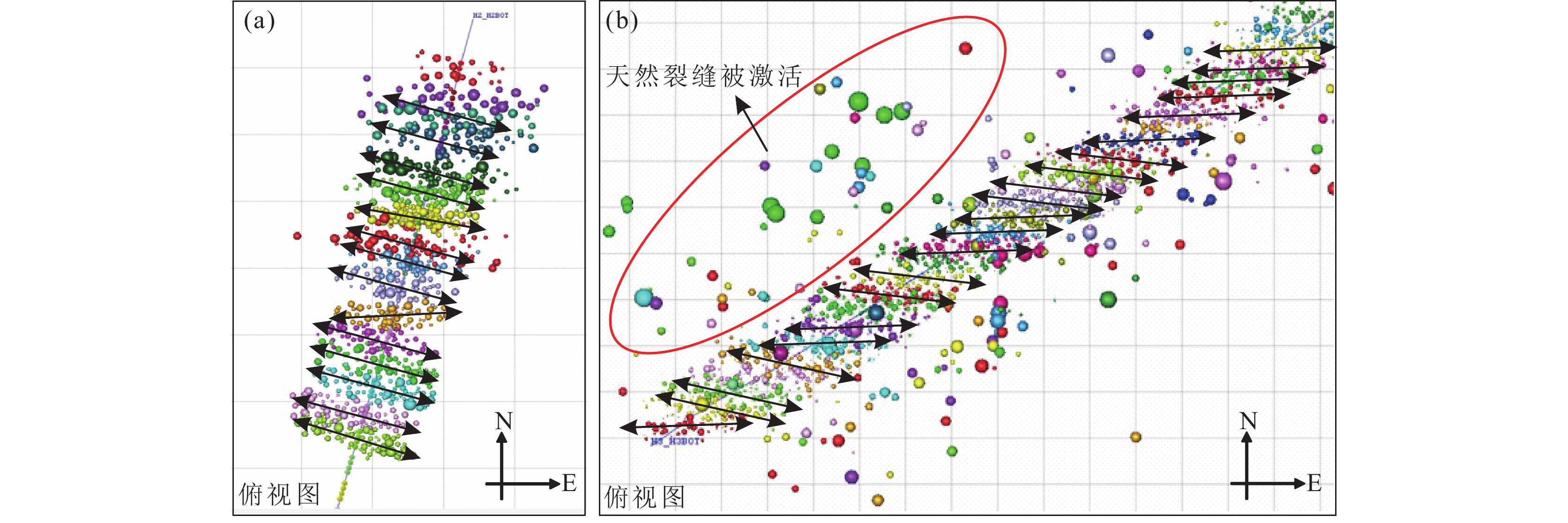

ResultsThe accuracy of interpreting dipole shear wave logs significantly increased when the bidirectional stress difference coefficient exceeds 0.2 and the shear wave anisotropy index is above 18%. In the strata with steep dips (>60°), it is essential to consider the influence of bidirectional stress differentials and high−angle fracture development on the interpretation of in−situ stress orientations. The in−situ stress orientations in the northern and southern synclinal regions of Yongchuan area predominantly follow east−west trend. However, these orientations exhibit significant deviations in anticlinal and fault−influenced zones, with maximum angular discrepancies of approximately 70°±5°. Based on the observed reverse trends in stress orientations above and below a specific stratigraphic level, we hypothesize that the neutral surface is located within the 1–2 layers of the Longmaxi Formation in the Yongchuan area. Furthermore, the fold−induced stress, ranging from 10 MPa to 30 MPa, significantly impacts the principal stress field and cannot be overlooked. As the distance from the fault decreases, Poisson’s ratio (ν) increases, leading to a deflection in the in−situ stress orientations and exhibiting greater sensitivity to changes in ν.

ConclusionsThe orientation of maximum principal stress promotes the preservation of shale gas in syncline areas, while high−angle natural fractures in anticline areas are more likely to develop into effective fractures. We recommend deploying horizontal wells with an SN−NEE orientation in syncline areas, and a NE orientation with a layered well layout in anticline and fault zones.

Highlights:We have proposed a multi−source methodology for determining in−situ stress orientations, integrating core analysis, wellbore structure reconstruction, extraction of sidewall seismic velocity anisotropy, inter−well microseismic monitoring, and geomechanical modeling of the well area. The optimal techniques have been established for ascertaining present in−situ stress orientations in shale reservoirs across various structural geological settings. Our investigation elucidates the impact of faults and folds on in−situ stress orientations and analyzes the influence of these stress orientation rotation on shale gas preservation and exploitation.

-

-

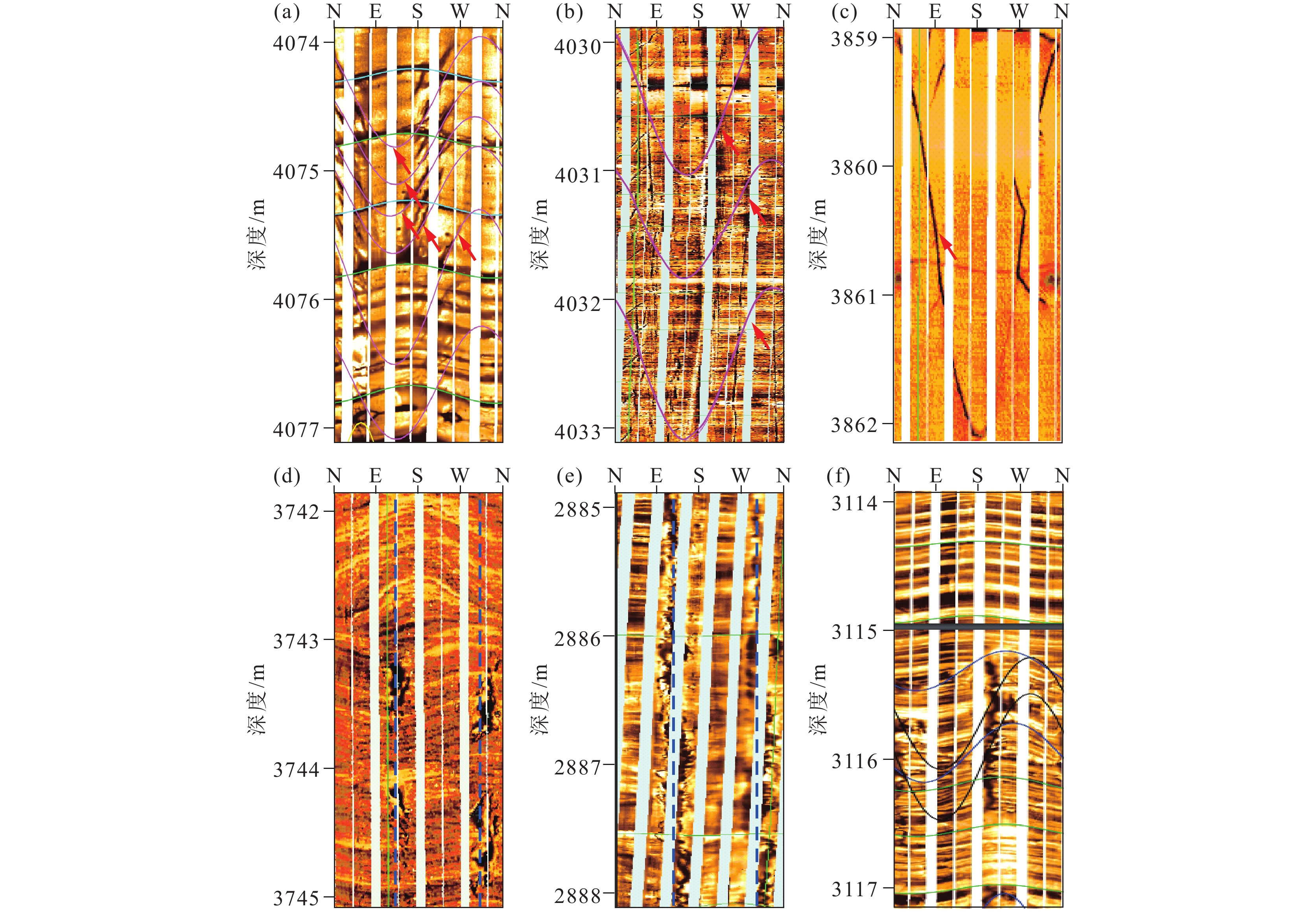

图 4 川南永川地区五峰组—龙马溪组成像测井中的诱导缝和井壁崩落实例

a—YY2井,诱导缝;b—YY2井,诱导缝;c—YY6井,诱导缝;d—YY6井,井壁崩落;e—YY9井,井壁崩落;f—YY6井,假崩落

Figure 4. Examples of drilling−induced fractures and wellbore breakouts in image logging in the Wufeng–Longmaxi Formation of the Yongchuan area, southern Sichuan Basin

a–Well YY2, drilling−induced fractures; b–Well YY2, drilling−induced fractures; c–YY6 well, drilling−induced fractures; d–YY6 well, wellbore breakouts; e–Well YY9, wellbore breakouts; f–Well YY6, false wellbore breakouts

图 7 川南永川地区水平井分支龙一段3开发小层的微地震监测事件

a—YY4−2水平井龙一段3开发小层监测结果;b—YY10−3水平井龙一段3开发小层监测结果

Figure 7. Microseismic monitoring events in the development layer 3 of the first member of Wufeng–Longmaxi Formation, a horizontal well branch in the Yongchuan area, southern Sichuan Basin

a–Monitoring results of YY4−2 horizontal well in the development layer 3 of the first member of Wufeng–Longmaxi Formation; b–Monitoring results of YY10−3 horizontal well in the development layer 3 of the first member of Wufeng–Longmaxi Formation

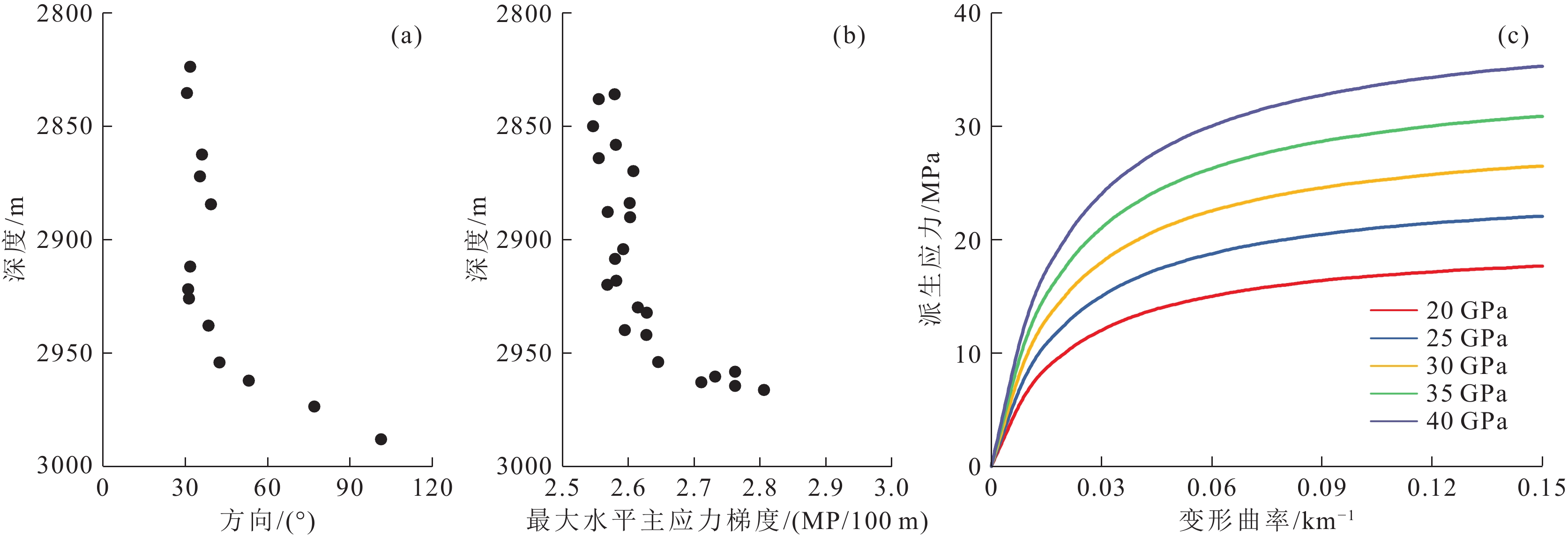

图 10 YY9井最大主应力方向随深度变化图(a)、最大主应力梯度随深度变化图(b)与不同杨氏模量下的变形曲率与派生应力关系(c)

Figure 10. Well YY9, the maximum horizontal stress orientation changes with depth (a), maximum horizontal stress gradient changes with depth (b) and the relationship between deformation curvature and derived stress under different Young's modulus (c)

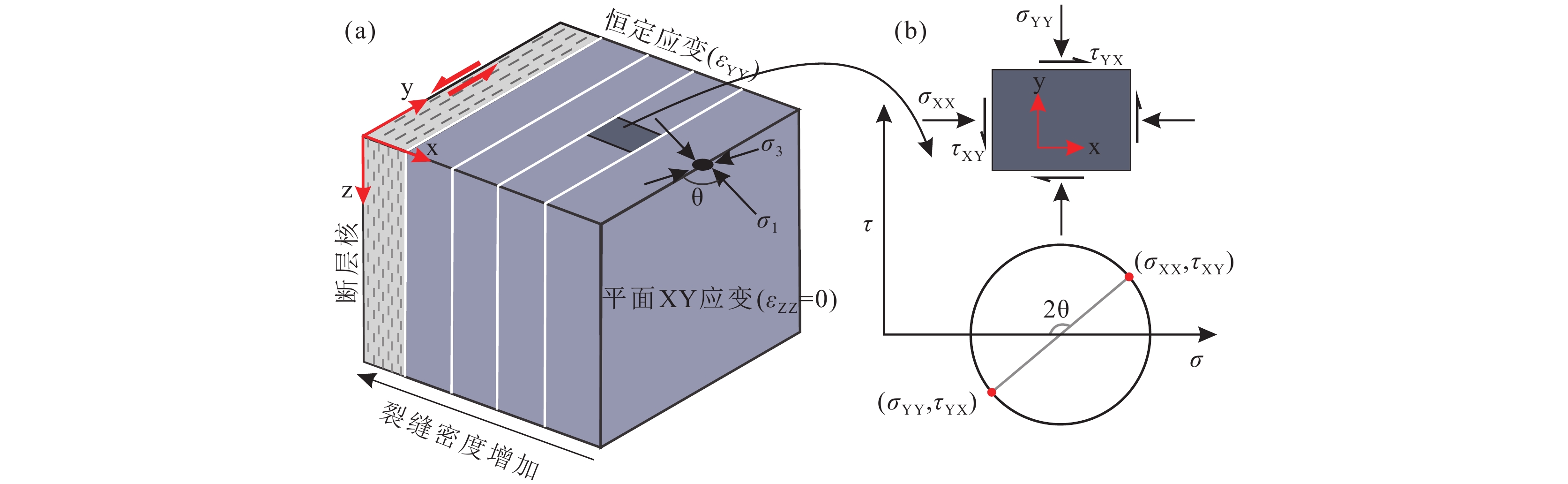

图 13 走滑断裂带的多层弹性模型(a,修改自Healy, 2008)与局部坐标系的应力分量状态(b)

Figure 13. Multi−layered elastic model of strike−slip fault zone (a, modified from Healy, 2008) and stress component state in the local coordinate system (b)

表 1 最大水平主应力方向测试结果

Table 1 Results of maximum horizontal principal stress orientation

井号 层位 井深/m 岩心定向方位 最大主应力与标志线夹角 最大主应力方向 YY2 1 4079.1 265.3° 20° 105.3° 2 4069.1 153.1° 130° 103.1° 3 4063.4 325.9° 130° 95.9° YY6 1 3880.9 124.3° 120° 64.3° 2 3876.5 309.7° 130° 85.7° 3 3870.9 245.7° 20° 79.7° 表 2 页岩储层现今地应力方向判断方法适用性

Table 2 Applicability of present−day in−situ stress orientation judgment method in the shale reservoir

地层变形情况 地层条件 岩心测试 钻井诱导缝 井壁崩落 偶极横波各向异性 震微地震监测 平缓地层 高两向差应力系数(>0.2) √ √ √ √ √ 低两向差应力系数(<0.2) × × × × √ 高陡地层 高角度裂缝发育且高两向差应力系数 √ √ × √ √ 高角度裂缝发育且低两向差应力系数 × × × × √ 中低角度裂缝发育且高两向差应力系数 √ √ √ √ √ 中低角度裂缝发育且低两向差应力系数 × × × × √ 注:√表示可以优选;×表示需要经过数据筛选和处理才可以使用。 表 3 川南永川地区目的层岩石力学参数赋值

Table 3 Assignment of rock mechanics parameters of the target layer in the Yongchuan area, southern Sichuan Basin

层号 构造分区 岩相分区 弹性模量/MPa 泊松比 内摩擦角 内摩擦力/MPa 抗拉强/MPa 厚度/m 1 北区 A 47588 0.32 46.99° 41.71 8.63 7.21 断层夹持区 B 29425 0.26 15.30° 18.13 4.43 背斜区 C 27473 0.23 27.40° 17.86 7.46 南区 D 36587 0.29 33.39° 17.55 9.54 2 北区 A 35364 0.35 42.35° 36.58 7.52 2.98 断层夹持区 B 30421 0.20 33.62° 10.50 3.41 背斜区 C 29713 0.22 36.22° 13.04 9.84 南区 D 32354 0.32 27.77° 28.25 7.53 3 北区 A 29331 0.28 27.70° 8.65 9.74 21.87 断层夹持区 B 28332 0.26 15.26 19.22 8.85 背斜区 C 27971 0.22 27.51 20.60 6.36 南区 D 39790 0.24 40.82 31.98 8.38 4 北区 A 34328 0.35 29.09 12.91 5.94 6.00 断层夹持区 B 22093 0.31 19.52 14.39 6.69 背斜区 C 20577 0.21 17.60 13.41 7.44 南区 D 32093 0.21 31.07 20.85 10.24 5 北区 A 29027 0.29 26.17 31.50 10.31 5.90 断层夹持区 B 26644 0.23 23.53 9.19 14.26 背斜区 C 23629 0.15 21.24 15.38 6.73 南区 D 28299 0.25 25.08 19.66 7.48 6 北区 A 22926 0.32 18.52 12.36 8.95 8.78 断层夹持区 B 20681 0.28 22.14 9.72 11.62 背斜区 C 19196 0.27 17.54 8.06 7.43 南区 D 26576 0.31 23.16 18.56 7.56 7 北区 A 23977 0.33 28.63 12.33 13.58 13.50 断层夹持区 B 20453 0.29 16.22 14.32 9.60 背斜区 C 19568 0.26 15.86 16.57 8.76 南区 D 24068 0.32 32.90 27.47 11.20 表 4 川南永川地区边界加载应力

Table 4 Boundary loading stress of Yongchuan area, southern Sichuan Basin

最大主应力/MPa 最大主应力梯度

/(MPa/100 m)最小主应力/MPa 最小主应力梯度

/(MPa/100 m)垂直应力/MPa 垂直应力梯度

/(MPa/100 m)101.94 2.74 87.46 2.32 94.50 2.49 表 5 川南永川地区最大水平主应力方向的单井解释值与预测值对比

Table 5 Comparison of single well interpretation value and predicted value in the orientation of maximum horizontal stress in the Yongchuan area, southern Sichuan Basin

构造部位 井位 层位 最大水平主应力方向 模拟最大水平主应力方向 误差绝对值 北部向斜区 YY2井 3小层 100° 98° 2.00% 抬升断块区 YY6井 3小层 60° 57° 5.00% 背斜褶皱区 YY7井 3小层 40° 43° 7.50% 背斜褶皱区 YY9井 3小层 55° 52° 5.45% 南部向斜区 YY10-3 3小层 92° 98° 6.50% 表 6 永川地区钻井的地压系数、含气量和产量统计

Table 6 Statistics of pressure coefficient, gas content and production of wells in Yongchuan area

构造

分区井号 ①-③小层含气量

/(m3/t)地压系数 测试产量

/(104m3/d)向斜区 YY1 4.79 1.77 11.26 YY2 4.89 1.91 7.34 YY3-1 4.79 1.99 6.16 背斜区 YY6 4.86 1.52 7.26 YY7 4.19 1.66 7.18 YY9 3.52 \ \ 注:“\”表示无数据。 -

[1] Barton C, Moos D, Tezuka K. 2009. Geomechanical wellbore imaging: Implications for reservoir fracture permeability[J]. AAPG Bulletin, 93(11): 1551−1569. doi: 10.1306/06180909030

[2] Brooke–Barnett S, Flottmann T, Paul P K, Busetti S, Hennings P, Reid R, Rosenbaum G. 2015. Influence of basement structures on in situ stresses over the Surat Basin, southeast Queensland[J]. Journal of Geophysical Research: Solid Earth, 120(7): 4946−4965. doi: 10.1002/2015JB011964

[3] Cao Feng, He Jianhua, Wang Yuanyuan, Deng Hucheng, Xu Qinglong. 2022. Methods to evaluate present–day in–situ stress direction for low anisotropic reservoirs in the second member of the Xujiahe Formation in Hechuan Area[J]. Advances in Earth Science, 37(7): 742−755 (in Chinese with English abstract).

[4] Casey M, Carreras J, Cobbold P R, Ramsay J G, White S H. 1980. Mechanics of shear zones in isotropic dilatant materials[J]. Journal of Structural Geology, 2(1/2): 143−147.

[5] Cuss R J, Rutter E H, Holloway R F. 2003. Experimental observations of the mechanics of borehole failure in porous sandstone[J]. International Journal of Rock Mechanics and Mining Sciences, 40(5): 747−761. doi: 10.1016/S1365-1609(03)00068-6

[6] Faulkner D R, Mitchell T M, Healy D, Heap M J. 2006. Slip on 'weak' faults by the rotation of regional stress in the fracture damage zone[J]. Nature, 444(7121): 922−925. doi: 10.1038/nature05353

[7] Faulkner D R, Jackson C A L, Lunn R J, Schlische R W, Shipton Z K, Wibberley C A J, Withjack M O. 2010. A review of recent developments concerning the structure, mechanics and fluid flow properties of fault zones[J]. Journal of Structural Geology, 32(11): 1557−1575. doi: 10.1016/j.jsg.2010.06.009

[8] Fu Yuhua, Wang Xingming, Yuan Haiping. 2009. Finite element inverse analysis of boundary load for tectonic stress field[J]. Rock and Soil Mechanics, 30(6): 1850−1855 (in Chinese with English abstract).

[9] Guo Tonglou, Xiong Liang, Lei Wei, Zhao Yong, Pang Heqing. 2023. Deep shale gas exploration and development in the Weirong and Yongchuan areas, South Sichuan Basin: Progress, challenges and prospect[J]. Natural Gas Industry, 42(8): 45−59 (in Chinese with English abstract).

[10] Guo Weixing, Tang Jianming, Ouyang Jiasui, Wang Tong, Wang Xin, Wang Yan. 2021. Characteristics of structural deformation in the southern Sichuan Basin and its relationship with the storage condition of shale gas[J]. Natural Gas Industry, 41(5): 11−19 (in Chinese with English abstract).

[11] Han Y, Feng Y, Li X, Zhang S. 2020. Evaluation of in–situ stress orientation: A laboratory approach combining paleomagnetic test and acoustic anisotropy test[J]. Journal of Petroleum Science and Engineering, 195: 107870. doi: 10.1016/j.petrol.2020.107870

[12] He Jianhua, Cao Feng, Deng Hucheng, Wang Yuanyuan, Li Yong, Xu Qinglong. 2022. Evaluation of in–situ stress in dense sandstone reservoirs in the second member of Xujiahe Formation of the HC area of the Sichuan Basin and its application to dense sandstone gas development[J]. Geology in China, 50(4): 1107−1121 (in Chinese with English abstract).

[13] He Jianhua, Li Yong, Deng Hucheng, Wang Yuanyuan, Ma Ruolong, Tang Jianming. 2023. Study on tectonic fracture characteristics and stage evolution of Longmaxi shale reservoir in Yongchuan, Southeastern Sichuan Basin[J]. Earth Science Frontiers, 31(3): 298−311 (in Chinese with English abstract).

[14] Healy D. 2008. Damage patterns, stress rotations and pore fluid pressures in strike–slip fault zones[J]. Journal of Geophysical Research, 113: B12407.

[15] Jaeger J C, Cook N G W, Zimmerman R. 2007. Fundamentals of Rock Mechanics, 4th Edition[M]. Malden, Mass: Blackwell.

[16] Ju W, Li Z, Sun W, Xu H. 2018. In–situ stress orientations in the Xiagou tight oil reservoir of Qingxi Oilfield, Jiuxi Basin, northwestern China[J]. Marine and Petroleum Geology, 98: 258−269. doi: 10.1016/j.marpetgeo.2018.08.020

[17] Ju Wei, Niu Xiaobing, Feng Shenbin, You Yuan, Xu Haoran, Wang Shengyu. 2020. The present–day in–situ stress state and fracture effectiveness evaluation in shale oil reservoir: A case study of the Yanchang formation Chang 7 oil–bearing layer in the Ordos Basin[J]. Journal of China University of Minging & Technology, 49(5): 931−940 (in Chinese with English abstract).

[18] Kingdon A, Fellgett M W, Williams J D O. 2016. Use of borehole imaging to improve understanding of the in–situ stress orientation of Central and Northern England and its implications for unconventional hydrocarbon resources[J]. Marine and Petroleum Geology, 73: 1−20. doi: 10.1016/j.marpetgeo.2016.02.012

[19] Liu X, Eckert A, Connolly P. 2016. Stress evolution during 3D single–layer visco–elastic buckle folding: Implications for the initiation of fractures[J]. Tectonophysics, 679: 140−155. doi: 10.1016/j.tecto.2016.04.042

[20] Liu Zhongchun, Lü Xinrui, Li Yukun, Zhang Hui. 2016. Mechanism of faults acting on in–situ stress field direction[J]. Oil and Gas Geology, 37(3): 387−393 (in Chinese with English abstract).

[21] Rajabi M, Tingay M, King R, Heidbach O. 2017. Present–day stress orientation in the Clarence–Moreton Basin of New South Wales, Australia: A new high density dataset reveals local stress rotations[J]. Basin Research, 29: 622−640. doi: 10.1111/bre.12175

[22] Reber J E, Schmalholz S M, Burg J P. 2010. Stress orientation and fracturing during three–dimensional buckling: Numerical simulation and application to chocolate–tablet structures in folded turbidites, SW Portugal[J]. Tectonophysics, 493(1/2): 187−195.

[23] Schmitt D R, Currie C A, Zhang L. 2012. Crustal stress determination from boreholes and rock cores: Fundamental principles[J]. Tectonophysics, 580: 1−26. doi: 10.1016/j.tecto.2012.08.029

[24] Stephansson O, Zang A. 2012. ISRM suggested methods for rock stress estimation—Part 5: Establishing a model for the In situ stress at a given site[J]. Rock Mechanics and Rock Engineering, 45(6): 955−969. doi: 10.1007/s00603-012-0270-x

[25] Tian H, Zeng L, Xu X, Li H, Luo B, Dong S. 2021. Factors influencing the in–situ stress orientations in shales: A case study of the Wufeng–Longmaxi Formations in the Jiaoshiba Area, southeastern Sichuan Basin, China[J]. Journal of Natural Gas Science and Engineering, 94: 104110. doi: 10.1016/j.jngse.2021.104110

[26] Warpinski N R, Schmidt R A, Northrop D A. 1982. In–situ stresses; the predominant influence on hydraulic fracture containment[J]. Journal of Petroleum Technology, 34(3): 653−664. doi: 10.2118/8932-PA

[27] Weng Jianqiao, Zeng Lianbo, Lü Wenya, Liu Qi, Zu Kewei. 2020. Width of stress disturbed zone near fault and its influencing factors[J]. Journal of Geomechanics, 26(1): 39−47 (in Chinese with English abstract).

[28] Wu Jianfa, Zhao Shengxian, Fan Cunhui, Xia Ziqiang, Ji Chunhai, Zhang Chenglin, Cao Lieyan. 2021. Fracture characteristics of the Longmaxi Formation shale and its relationship with gas–bearing properties in Changning area, southern Sichuan[J]. Acta Petrolei Sinica, 42(4): 428−446 (in Chinese with English abstract).

[29] Xie Bing, Bai Li, Zhao Ailin, Zhang Hongying, Wang Yue. 2017. Application of sonic scanner logging to fracture effectiveness evaluation of carbonate reservoir: A case from Sinian in Sichuan Basin[J]. Lithologic Reservoirs, 29(4): 117−123 (in Chinese with English abstract).

[30] Xu Ke, Dai Junsheng, Shang Lin, Fang Lu, Feng Jianwei, Du He. 2019. Characteristics and influencing factors of in–situ stress of Nanpu Sag, Bohai Bay basin, China[J]. Journal of China University of Mining and Technology, 48(3): 570−583 (in Chinese with English abstract).

[31] Xu S, Liu R, Hao F, Engelder T, Yi J, Zhang B, Shu Z. 2019. Complex rotation of maximum horizontal stress in the Wufeng–Longmaxi shale on the eastern margin of the Sichuan Basin, China: Implications for predicting natural fractures[J]. Marine and Petroleum Geology, 109: 519−529. doi: 10.1016/j.marpetgeo.2019.06.008

[32] Yang Fan, Mei Wenbo, Li Liang, Sun Zening, An Qi, Yang Qi, Lu Meiquan, Yang Ruiyue. 2023. Propagation of hydraulic fractures in thin interbedded tight sandstones[J]. Coal Geology and Exploration, 51(7): 61−71 (in Chinese with English abstract).

[33] Zeng L, Lyu W, Li J, Guo Y, Yang Y, Dong S, Liu X, Zu K. 2019. Variation in the orientation of the maximum horizontal stress in thick channel–fill sandstones with low–permeability: A case of the Bonan oil field in the Bohai Bay Basin, eastern China[J]. Marine and Petroleum Geology, 107: 32−40. doi: 10.1016/j.marpetgeo.2019.04.041

[34] Zhang Peixian, Gao Quanfang, He Xipeng, Gao Yuqiao, Liu Ming, He Guisong, Zhang Zhiping, Zhou Dina. 2023. Characteristics of in–situ stress field and its influence on shale gas production from Longmaxi Formation in Nanchuan area[J]. Petroleum Geology and Recovery Efficiency, 30(4): 55−65 (in Chinese with English abstract).

[35] Zhang S, Ma X. 2021. How does in situ stress rotate within a fault zone? Insights From explicit modeling of the frictional, fractured rock mass[J]. Journal of Geophysical Research: Solid Earth, 126(11): e2021JB022348. doi: 10.1029/2021JB022348

[36] Zhang Y, Zhang J, Yuan B, Yin S. 2018. In–situ stresses controlling hydraulic fracture propagation and fracture breakdown pressure[J]. Journal of Petroleum Science and Engineering, 164: 164−173. doi: 10.1016/j.petrol.2018.01.050

[37] Zhao Jinghui, Gao Yuqiao, Chen Zhenlong, Guo Tao, Gao Xiaokang. 2021. Stress state of deep seam and its influence on development performance of CBM wells in South Yanchuan Block, Odors Basin[J]. Geology in China, 48(3): 785−793 (in Chinese with English abstract).

[38] Zhou Wen, Yan Changhui, Wang Shize, Xie Runcheng, Zhang Shaonan, Deng Hucheng, Shan Yuming, Chen Qing, Zhang Yinde. 2007. Evaluation Method of Reservoir In–situ Stress and Its Application[M]. Beijing: Geological Publishing House (in Chinese with English abstract).

[39] Zoback M L. 1992. First–and second–order patterns of stress in the lithosphere: The World Stress Map Project[J]. Journal of Geophysical, 97(B8): 11703−11728.

[40] Zoback M D, Barton C A, Brudy M, Castillo D A, Finkbeiner T, Grollimund B R, Moos D B, Peska P, Ward C D, Wiprut D J. 2003. Determination of stress orientation and magnitude in deep wells[J]. International Journal of Rock Mechanics and Mining Sciences, 40(7/8): 1049−1076.

[41] 曹峰, 何建华, 王园园, 邓虎成, 徐庆龙. 2022. 合川地区须二段低各向异性储层现今地应力方向评价方法[J]. 地球科学进展, 37(7): 742−755. doi: 10.11867/j.issn.1001-8166.2022.7.dqkxjz202207006 [42] 付玉华, 王兴明, 袁海平. 2009. 构造应力场边界载荷反演的有限元逆逼近法[J]. 岩土力学, 30(6): 1850−1855. doi: 10.3969/j.issn.1000-7598.2009.06.056 [43] 郭彤楼, 熊亮, 雷炜, 赵勇, 庞河清. 2022. 四川盆地南部威荣、永川地区深层页岩气勘探开发进展、挑战与思考[J]. 天然气工业, 42(8): 45−59. doi: 10.3787/j.issn.1000-0976.2022.08.005 [44] 郭卫星, 唐建明, 欧阳嘉穗, 王同, 王信, 王岩. 2021. 四川盆地南部构造变形特征及其与页岩气保存条件的关系[J]. 天然气工业, 41(5): 11−19. doi: 10.3787/j.issn.1000-0976.2021.05.002 [45] 何建华, 曹峰, 邓虎成, 王园园, 李勇, 徐庆龙. 2022. 四川盆地HC地区须二段致密砂岩储层地应力评价及其在致密气开发中的应用[J]. 中国地质, 50(4): 1107−1121. [46] 何建华, 李勇, 邓虎成, 王园园; 马若龙, 唐建明. 2024. 川东南永川地区龙马溪组页岩储层构造裂缝特征及期次演化研究[J]. 地学前缘, 31(3): 298−311. [47] 鞠玮, 牛小兵, 冯胜斌, 尤源, 徐浩然, 王胜宇. 2020. 页岩油储层现今地应力场与裂缝有效性评价—以鄂尔多斯盆地延长组长7油层组为例[J]. 中国矿业大学学报, 49(5): 931−940. [48] 刘中春, 吕心瑞, 李玉坤, 张辉. 2016. 断层对地应力场方向的影响机理[J]. 石油与天然气地质, 37(3): 387−393. doi: 10.11743/ogg20160311 [49] 翁剑桥, 曾联波, 吕文雅, 刘奇, 祖克威. 2020. 断层附近地应力扰动带宽度及其影响因素[J]. 地质力学学报, 26(1): 39−47. doi: 10.12090/j.issn.1006-6616.2020.26.01.004 [50] 吴建发, 赵圣贤, 范存辉, 夏自强, 季春海, 张成林, 曹埒焰. 2021. 川南长宁地区龙马溪组富有机质页岩裂缝发育特征及其与含气性的关系[J]. 石油学报, 42(4): 428−446. [51] 谢冰, 白利, 赵艾琳, 张红英, 王玥. 2017. Sonic Scanner声波扫描测井在碳酸盐岩储层裂缝有效性评价中的应用—以四川盆地震旦系为例[J]. 岩性油气藏, 29(4): 117−123. doi: 10.3969/j.issn.1673-8926.2017.04.014 [52] 徐珂, 戴俊生, 商琳, 房璐, 冯建伟, 杜赫. 2019. 南堡凹陷现今地应力特征及影响因素[J]. 中国矿业大学学报, 48(3): 570−583. [53] 杨帆, 梅文博, 李亮, 孙泽宁, 安琦, 杨琦, 陆美全, 杨睿月. 2024. 薄互层致密砂岩水力压裂裂缝扩展特征研究[J]. 煤田地质与勘探, 51(7): 61−71. [54] 张培先, 高全芳, 何希鹏, 高玉巧, 刘明, 何贵松, 张志萍, 周頔娜. 2023. 南川地区龙马溪组页岩气地应力场特征及对产量影响分析[J]. 油气地质与采收率, 30(4): 55−65. [55] 赵景辉, 高玉巧, 陈贞龙, 郭涛, 高小康. 2021. 鄂尔多斯盆地延川南区块深部地应力状态及其对煤层气开发效果的影响[J]. 中国地质, 48(3): 785−793. doi: 10.12029/gc20210309 [56] 周文, 闫长辉, 王世泽, 谢润成, 张哨楠, 邓虎成, 单钰铭, 陈青, 张银德. 2007. 油气藏现今地应力场评价方法及应用[M]. 北京: 地质出版社.

下载:

下载: