-

摘要:研究目的

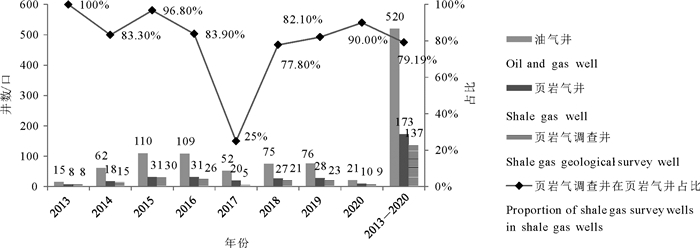

近年来,中国地质调查局部署实施了173口页岩气勘查井,完成31万余米进尺,重点开展长江经济带页岩气调查科技攻坚战,取得了震旦系、寒武系和志留系页岩气调查的重大突破和二叠系页岩气调查重要发现,开辟了页岩气勘查的新区、新层系、新类型和新认识。基础地质调查井作为油气发现的重要手段,可实现全井段取心,具有成本低、周期短等特点,一般部署在邻井资料缺乏的勘探空白区。

研究方法为了给页岩气调查提供钻井工程方面的技术支持,本文梳理了十年来中国地质调查局部署实施的钻井工程,对取得的一系列钻井技术进行了分类和归纳整理。

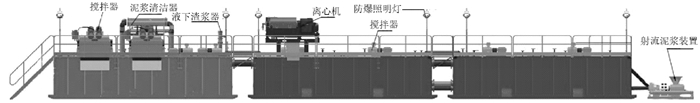

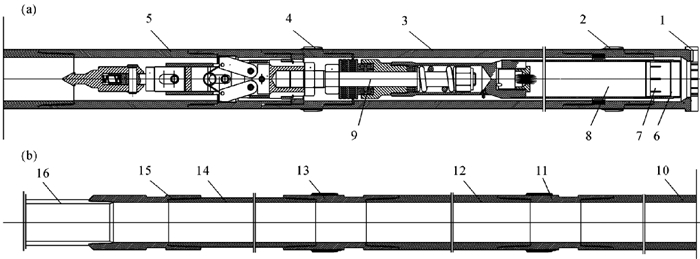

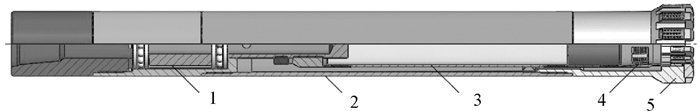

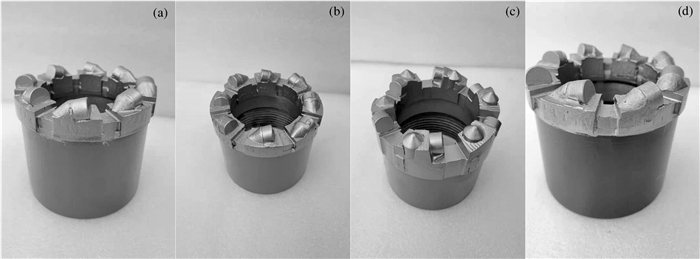

研究结果总结了一整套在地质钻探装备与技术基础上创新发展的高效页岩气钻井装备与技术体系:(1)形成了页岩气地质调查井地面装备,包括适应于页岩气井井控安全的改进型立轴钻机、符合绿色勘探要求的钻井液固控循环系统等;(2)高效取心工具及钻进工艺,重点介绍了大直径绳索取心钻具、KT系列取心钻具等取心钻具,倒塔式钻具组合工艺、空气跟管技术等钻进工艺等;(3)阐述了高效取心钻头研究进展,包括异形齿PDC钻头、孕镶块钻头、孕镶金刚石钻头等3类钻头及其应用效果;(4)简要论述了安全钻井技术及复杂处理进展,介绍了页岩气勘探钻井液技术、控压钻进技术以及失返、卡钻等钻井复杂处理。此外,围绕新区新层系页岩气勘探特点,给出下一步开展页岩气钻井技术研究的方向。

结论通过综述上述研究进展,可为页岩气勘探钻井工程设计和施工提供有益参考。

创新点:(1)本文研究总结页岩气调查井钻井装备、取心工具及新型钻头、井眼稳定技术等最新成果;(2)提出小井眼固井技术、复杂地层套管技术、钻头设计与优选、钻井液技术等安全钻进与钻井提速发展方向。

Abstract:This paper is the result of oil and gas survey engineering.

ObjectiveFocusing on the scientific and technological task of shale gas investigation in the Yangtze River economic belt, China Geological Survey has deployed and implemented 173 shale gas exploration wells, completed more than 310000 m of drilling footage in recent years. Major breakthroughs in the shale gas investigation of Sinian system, Cambrian system, and Silurian system, and important discoveries in the shale gas investigation of Permian system has been achieved. It opened new areas, new strata, new types, and new insights of shale gas exploration. The basic geological survey wells are used to drill cores with low cost and short cycle. They are generally deployed in new blocks and new strata with insufficient data from adjacent wells. Aiming to provide technical support in drilling engineering for shale gas investigation.

MethodsThis article analyzes the related research progress of drilling projects deployed and implemented by China Geological Survey over the past decade, and a series of drilling technologies achieved have been classified and summarized.

ResultsThe high-efficiency shale gas drilling equipment and technology system based on the innovative development of geological drilling equipment and technology are summarized: (1) Surface equipment for shale gas geological survey wells has been formed, including improved vertical shaft drilling rig suitable for well control safety of shale gas wells, drilling fluid solid control circulation system meeting the requirements of green exploration, etc.; (2) High-efficiency coring tools and drilling technology, focusing on the coring tools such as large-diameter wireline coring tools, KT series coring tools, inverted tower drilling tool assembly technology, air pipe following technology, etc.; (3) The research progress of high efficiency coring bits is described, including three types of bits, such as special-tooth PDC bits, impregnated block bits and impregnated diamond bits, and their application effects; (4) The progress of safe drilling technology and complex treatment is briefly discussed. The shale gas exploration drilling fluid technology, pressure control drilling technology, and drilling complex treatment such as lost return and sticking is introduced. In addition, the direction of shale gas drilling technology research is given.

ConclusionsThe review of above research progress can provide useful reference for shale gas exploration drilling engineering design and construction.

-

1. 引言

石泉–旬阳金矿带整装勘查区7个图幅区1∶50 000水系沉积物测量始于2013年(图1),其中饶峰幅、迎丰街幅和安康幅1∶50 000水系沉积物测量由中国地质调查局发展研究中心2016—2018年组织实施;铁佛寺幅、汉阴幅、大河口幅和赵家湾幅1∶50 000水系沉积物测量由中国地质调查局西安地质调查中心2013—2015年组织实施,承担单位均为陕西地矿第一地质队有限公司。

陕西石泉–旬阳金矿带整装勘查区位于秦岭造山带中部的南秦岭构造带,在漫长地质历史演化中,该区地层经历了多期变形,构造样式以褶皱、滑脱和韧性剪切带最为典型。地层区划隶属于华南地层大区中的牛山地层小区(韩芳林等,2013)(图2)。因盖层与基底间拆离滑脱,以出露滨海环境下形成的震旦纪—早古生代黑色浅变质强变形细碎屑岩系建造最为典型(张复新等,2009;唐永忠等,2012)。区内出露地层有古元古代杨坪岩组、耀岭河岩组中基性火山岩,古生代沉积—浅变质岩,中晚志留世—早泥盆世沉积地层发育不全(刘国惠和张寿广,1993)。

石泉–旬阳金矿带整装勘查区1∶50 000水系沉积物测量从2013年7月份编写项目设计书开始,各项工作均按相关技术要求执行。项目总体按三个阶段进行,第一阶段组织地球化学勘查技术人员进行1∶50 000水系沉积物测量采样工作;第二阶段检查、核对、整理和处理数据,圈定地球化学异常;第三阶段编制地球化学系列图件,建立完善石泉–旬阳金矿带整装勘查区的区域地球化学数据库,筛选并进行异常查证工作。

陕西石泉–旬阳金矿带整装勘查区水系沉积物测量原始数据集元数据简表见表1。

表 1 数据库(集)元数据简表条目 描述 数据库(集)名称 陕西石泉–旬阳金矿带整装勘查区饶峰幅等7个图幅区1∶50 000水系沉积物测量原始数据集 数据库(集)作者 谈 乐,陕西地矿第一地质队有限公司

张永强,陕西地矿第一地质队有限公司

刘小朋,陕西地矿第一地质队有限公司

李小明,陕西地矿第一地质队有限公司

王才进,陕西地矿第一地质队有限公司数据时间范围 2013—2018年 地理区域 陕西省石泉县–旬阳县地区 数据格式 *.xlsx 数据量 2.01MB 数据服务系统网址 http://dcc.cgs.gov.cn 基金项目 中国地质调查局地质调查项目(121201004000150017-53、121201004000160901-54、121201004000172201-45、12120113048100) 语种 中文 数据库(集)组成 数据集为Excel表格,包括7个独立的工作表(sheet),分别为“饶峰幅采样点位及元素分析结果表”、“铁佛寺幅采样点位及元素分析结果表”、“汉阴幅采样点位及元素分析结果表”、“大河口幅采样点位及元素分析结果表”、“赵家湾幅采样点位及元素分析结果表”、“迎丰街幅采样点位及元素分析结果表”、 “安康幅采样点位及元素分析结果表” 2. 野外工作方法

2.1 方法选择

勘查区属湿润−半湿润中低山丘陵自然景观区(樊会民和李方周,2013),湿润、多雨、强剥蚀、深切割,以物理风化为主,沟系冲、洪积物具粗岩屑性质(刘劲松等,2016),适宜开展水系沉积物测量。根据《地球化学普查规范(1∶50 000)》(DZ/T 0011−2015),结合勘查区地球化学景观特点,确定本次地球化学普查采样介质为水系沉积物,采样密度4~8点/km2,样品粒级选择−20目~+60目。

2.2 样品采集

2.2.1 采样部位

勘查区1∶50 000水系沉积物测量采样部位均选择在河沟底部或河岸与水面接触处(张源等,2018)。在间歇性水流地区或主干河道中,主要在河床底部采样;在水流湍急的河道中选择在水流变缓处、水流停滞处、转石背后、水流由窄变宽处,以及河道转弯内侧有较多细粒物质聚集处采样。

2.2.2 采样物质

采样介质以代表原生地质找矿信息的基岩物质成分为原则,采样物质为水系沉积物中的淤泥、粉砂或细砂。

2.2.3 采样方法

勘查区水系沉积物所采集的样品为粗−细粒级混合的粒级段,有效地避开了腐植层取样,样品采集过程中,加强了对蚀变−矿化强烈或重点找矿地段的加密采样工作。采用的具体技术方法如下:

①采样前,先用采样勺拨去地表浮土或腐植层,再进行取样。

②每次装袋前,首先检查布样袋,看是否有开线或破洞。含水样品装袋时先用塑料袋分装后再装入布样带中,防止袋内水分相互淋滤造成湿样互相污染。

③为了提高样品的代表性,样品采集均在采样点位上下游20~30 m范围内3~5处多点采集,组合成一件样品。

④样品采集避开了矿山开发、村镇、水坝、淤地造田、交通要道和路口造成的污染物及岸边崩塌堆积物地段。

2.2.4 野外定点

陕西石泉–旬阳金矿带整装勘查区涉及1∶50 000图幅共7幅(表2),图幅坐标系采用1980西安坐标系,中央经线为111°,图幅涉及地理数据均在陕西地理信息测绘局购买。

表 2 陕西石泉−旬阳金矿带整装勘查区涉及的7幅1∶50 000地形图图幅名称 图幅号 饶峰幅 I49E17001 迎丰街幅 I49E18002 铁佛寺幅 I49E18003 汉阴幅 I49E19003 大河口幅 I49E19004 赵家湾幅 I49E19005 安康幅 I49E02005 用1∶50 000标准地形图作为水系沉积物测量野外工作手图,采用手持IGS-100掌上机(李超岭等,2002)结合地形图进行野外定点。定点实际距离误差均小于30 m,即在手图上均小于1 mm。

2.3 采样点密度

本次共采集水系沉积物样品13 169件。根据勘查区地形地貌特点、景观条件、地质特征,本次1∶50 000水系沉积物测量分别采用了不同的采样布局和采样密度:加密区(即指1∶200 000化探异常明显、矿化信息相对较多、基岩面积大、第四系分布面积较少的地区,除正常布点外,成矿有利地段适当加密)采样密度为5.18~5.46点/km2;一般工作区(即指第四系分布面积相对较多,基岩出露面积小或零星,1∶200 000化探异常弱的地区)采样密度为:4.1~4.3点/km2;放稀区(即山间盆地)采样密度为3.13~3.52点/km2。该采样密度组合可有效地控制工作区内绝大多数汇水面积,经济实用,可有效地达到地球化学普查的目的。

2.4 样品加工

样品加工基本流程为:自然干燥→揉碎→过筛→混匀→称量缩分→填写标签→装袋→填写送样单→装箱(陈玉明和陈秀法,2018)。

样品干燥方式采取日晒风干。干燥过程中及时揉搓样品,防止结块,并用木槌适当敲打。

② 样品干燥后过−20目~+60目尼龙筛,对筛下样品用对角线折叠法混匀,缩分后装入纸样袋中,其重量均≥310 g。

③按样品缩分法将加工好的样品缩分成两份各≥150 g,一份装牛皮纸袋送检,另一份装塑料瓶封装当副样留存。

3. 样品分析测试方法

样品分析测试工作先后由具备岩矿测试甲级资质的自然资源部西安矿产资源监督检测中心和陕西地矿局汉中地质大队有限公司实验室承担,严格执行《地球化学普查(比例尺1∶50 000)规范样品分析技术的补充规定》。

3.1 实验室样品加工与制备

实验室配备有专职样品管理人员,负责样品的验收和保管,并严格按照规范要求办理样品交接手续。

以50件样品为一个分析批次进行编码和样品加工,每一个分析批次中随机插入4个国家一级标准物质,然后进入计算机,打印出分析号与送样号的对照表,以供样品管理人员在管理样品、填写汇总表等准备工作中使用,样品随后由样品管理人员下达至碎矿间进行无污染碎样。

化探样品在加工前均在60℃以下充分烘干。在大批量样品加工前,先对岩屑样分别进行玛瑙球数量、球磨时间的最佳条件试验,使其细磨后样品粒度满足1∶50 000区域地球化学调查的要求为原则。要求细磨加工后样品粒度达到−0.074 mm(−200目)占90%以上。

样品管理人员对每批样品的加工粒度是否达到规定要求进行检查;检查合格后,按规定插入指定的监控样及国家一级标样,同时依照密码编号分出内检样,随后交由质量管理人员下达分析任务。

3.2 分析项目及分析方法

根据项目任务书、合同书及总体设计要求,2013—2015年度 1∶50 000水系沉积物测量分析项目为:Au、Ag、Cu、Pb、Zn、As、Sb、Hg、V、Mo、Ti、W共12种元素。2016—2018年度1∶50 000水系沉积物测量分析项目为Au、Ag、Cu、Pb、Zn、As、Sb、Hg、Bi、Sn、W、Mo、Cd、Co、Cr、Ni共计16种元素。

采用光栅光谱仪(OES)、原子荧光仪(AFS)、等离子质谱仪法(ICP-MS)、发射光谱法(GF-AAS)等仪器进行分析测试,所有元素报出率均为100%。勘查区18种元素分析测试方法配套方案见表3。

表 3 勘查区18种元素分析方法、检出限及报出率统计表分析方法 元素含量 1∶50 000地球化学测量规定检出限 所用方法检出限 报出率(%) GF-AAS w(Au)/10−9 0.3~1 0.23 100 F-AAS w(Cu)/10−6 2 1.00 100 w(Zn)/10−6 20 5.00 100 HG-AFS w(As)/10−6 0.5~1 0.20 100 w(Sb)/10−6 0.3 0.05 100 CV-AFS w(Hg)/10−9 10~50 2.00 100 w(Bi)/10−6 0.3 0.1 100 ICP-OES w(Ti)/10−6 100 9.3 100 w(V)/10−6 20 5 100 OES w(Ag)/10−6 0.050 0.019 100 w(Sn)/10−6 2 0.5 100 ICP-MS w(Pb)/10−6 5~10 0.91 100 w(W)/10−6 1 0.048 100 w(Mo)/10−6 1 0.056 100 w(Ni)/10−6 1 0.21 100 w(Co)/10−6 1 0.10 100 w(Cr)/10−6 10 1.00 100 w(Cd)/10−6 0.2 0.02 100 4. 数据样本描述

石泉–旬阳金矿带整装勘查区饶峰幅等7个图幅1∶50 000水系沉积物测量原始数据集为Excel表格型数据,包括7个独立的工作表(sheet),分别为“饶峰幅水系沉积物测量采样点位及元素分析结果表”、“迎丰街幅水系沉积物测量采样点位及元素分析结果表”、“铁佛寺幅水系沉积物测量采样点位及元素分析结果表”、“汉阴幅水系沉积物测量采样点位及元素分析结果表”、“大河口幅水系沉积物测量采样点位及元素分析结果表”、“赵家湾幅水系沉积物测量采样点位及元素分析结果表”、“安康幅水系沉积物测量采样点位及元素分析结果表”(宋相龙等,2017)。每个工作表(sheet)包含如下内容:样品编号、高斯坐标、图幅号、地层、分析结果(铁佛寺幅、大河口幅、汉阴幅、赵家湾幅分析元素为Au、Hg、Ag、Cu、Pb、Zn、Mo、As、Sb、Ti、V、W;迎丰街幅、饶峰幅、安康幅分析元素为Au、Ag、Cu、Pb、Zn、As、Sb、Hg、Bi、Sn、W、Mo、Cd、Co、Cr、Ni)、备注。数据结构见表4。

表 4 陕西石泉−旬阳金矿带整装勘查区水系沉积物测量数据结构表序号 数据项名称 量纲 数据类型 字段长度 实例 1 样品编号 − 字符型 20 57C2 2 图幅号 − 字符型 20 I49E018002 3 地层 − 字符型 20 O3-S1b 4 高斯横坐标 − 字符型 20 255460 5 高斯纵坐标 − 字符型 20 3672075 6 经度 − 字符型 20 108°22′45″ 7 纬度 − 字浮型 20 33°08′48″ 8 Au 10−9 浮点型 20 1.03 9 Ag 10−6 浮点型 20 42 10 Cu 10−6 浮点型 20 35.9 11 Pb 10−6 浮点型 20 35.9 12 Zn 10−6 浮点型 20 83.7 13 As 10−6 浮点型 20 3.88 14 Sb 10−6 浮点型 20 2.13 15 Hg 10−9 浮点型 20 49 16 Bi 10−6 浮点型 20 0.85 17 Sn 10−6 浮点型 20 3 18 W 10−6 浮点型 20 2.14 19 Mo 10−6 浮点型 20 0.93 20 Cd 10−6 浮点型 20 0.1 21 Co 10−6 浮点型 20 22.3 22 Cr 10−6 浮点型 20 94.6 23 Ni 10−6 浮点型 20 41.9 24 Ti 10−6 浮点型 20 − 25 V 10−6 浮点型 20 − 5. 数据质量和评估

5.1 原始数据质量

铁佛寺幅、汉阴幅、大河口幅和赵家湾幅地球化学测量样品测试过程中以50件样品为一个分析批次进行编码和样品加工,每一个分析批次中随机插入4个国家一级标准物质,分别为GBW07302a、GBW07304a、GBW07309、GBW07318,对分析过程的精密度进行监控。另外随机分段加入12件国家一级标准物(每500件样品插入一次),共插入15次,对分析过程的准确度进行监控,并对样品中部分高值和低值进行了抽查分析,抽查样品数量比例为2.6%。

饶峰幅、迎丰街幅和安康幅地球化学测量样品测试过程中以50件样品为一个分析批进行编码和样品加工,共分为243批。每一个分析批次中随机插入购买于中国地质科学院地球物理地球化学勘查研究所的4个国家一级标准物质对分析过程的准确度进行监控。其中Au、Ag、Hg、Pb、Sn、As、Sb和Bi共8种元素插入GSD-10、GSD-14、GSD-18、GSD-20控制分析过程精密度;Cr、Co、Ni、Cu、Zn、Mo、Cd和W共8种元素插入GSD-8a、GSD-9、GSD-10、GSD-14控制分析过程精密度,并对样品中部分高值和低值进行了抽查分析,抽查样品数量比例为4.1%。

本次检测工作中,分析元素内检(重复样)合格率均在95.00%以上;元素报出率均达到100%;元素异常复查合格率均为97.5%以上;所选用分析方法的检出限均满足DZ/T0130.4−2006中1∶50 000化探样品标准要求。方法的精密度:对所选一级标准物质检测的△lgC平均值在(−0.099~0.099)以内。方法准确度:对所选一级标准物质检测的△lgC平均值在(−0.099~0.099)以内。所选分析方法的检出限、精密度和准确度均满足《地球化学普查(比例尺1∶50 000)规范样品分析技术的补充规定》的质量要求。

上述质量参数数据表明,本次检测的分析质量完全符合《地球化学普查(比例尺1∶50 000)规范样品分析技术的补充规定》及DZ0130.4−2006的质量要求。

5.2 成果数据库建设质量

陕西石泉–旬阳金矿带整装勘查区饶峰幅等7个图幅区1∶50 000水系沉积物测量成果数据库建设(万常选等,2009)均按照化探数据模型采用DGSS软件平台实现(庞健峰等,2017),样品中各分析元素属性结构均参照中国地质调查局固体矿产勘查数据库内容与结构(左群超等,2018;李超岭等,2013)填写,数据结构内容完整齐全。所形成的7幅1∶50 000水系沉积物测量数据库已由中国地质调查局西安地质调查中心及中国地质调查局发展研究中心专家评审验收,评分93分,评为“优秀级”,已完成相关数据库汇交。

6. 结论

本次数据集工作区范围是由中国地质调查局西安地质调查中心与中国地质调查局发展研究中心组织实施的陕西石泉–旬阳金矿带整装勘查区内饶峰幅等7幅图3 010 km2 1∶50 000水系沉积物测量工作,是陕西石泉–旬阳金矿带整装勘查区内首次系统性的采用统一采样方法、分析测试方法、统一分析元素,也是本整装勘查区内首次规范化建立地球化学数据库,获得了珍贵的第一手地球化学测量资料。

本数据集成果指导在整装勘查区内圈定金找矿靶区10处,金成矿远景区12处❶,其中在圈定的陕西省汉阴县双河口一带金找矿靶区内新发现坝王沟金矿点,通过后期省地勘基金投入,金(333+334)资源量30吨;在圈定的陕西省安康市汉滨区将军山一带金找矿靶区内新发现早阳金矿点,通过后期省地勘基金投入,金(333+334)资源量20吨。另外运用本数据集成果新发现4处金矿点,分别为陕西省宁陕县堰沟金矿点、陕西省安康市汉滨区柳坑金矿点、陕西省石泉县石桥金矿点、陕西省石泉县栈房金矿点,均有一定的找矿潜力。另外,本数据集成果指导我省找到2~4处新的大型金矿产资源开发基地。

注释:

❶张永强, 孙健, 谈乐. 2018. 陕西石泉−旬阳金矿带整装勘查区矿产调查与找矿预测2016—2018年子项目总成果报告[R]. 安康:陕西地矿第一地质队有限公司, 1−260.

1. Introduction

The measurement of 1∶50 000 stream sediments across 7 map sheets of the integrated survey area of the Shiquan-Xunyang gold zone began in 2013 (Fig. 1), of which those in the Raofeng, Yingfengjie and Ankang map sheets were organized by the Development and Research Center of China Geological Survey in 2016—2018; those in the Tiefosi, Hanyin, Dahekou and Zhaojiawan map sheets were organized by the Xi’an Center of China Geological Survey in 2013—2015, and both were conducted by the Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co. Ltd..

The integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi, located at the South Qinling tectonic zone in the midst of the Qinling orogeny, has experienced multi-stage deformations in its long history of geological evolution, where the typical tectonic patterns are folding, detachment and ductile shearing zones. In terms of stratigraphic regionalization, it belongs to the Niushan stratigraphic sub-region of the South China stratigraphic super-region (Han FL et al., 2013) (Fig. 2). Due to decoupling detachment between the overlying strata and basement, the outcrop in the area is characterized by the formation of Sinian−early-Paleozoic, black, low-metamorphic, strongly-deformed fine clastic rock series, which were formed in the coastal sea environment (Zhang FX et al., 2009; Tang YZ et al., 2012). The outcropped strata within the area include the Paleoproterozoic Yangpingyan Formation, the basic volcanic rock of the Yaolinghe Formation and Paleozoic sedimentary−low-metamorphic rocks, where mid- and late-Silurian−early-Devonian sedimentary strata are poorly developed (Liu GH and Zhang SG, 1993).

The measurement of the 1∶50 000 stream sediments in the integrated survey area of the Shiquan-Xunyang gold ore zone began with preparation of the project design in July 2013, all works being done in accordance with the relevant technical specifications. The project was completed in three stages: Stage 1, organization of the geochemical staff to take samples for the measurement of the 1∶50 000 stream sediments; Stage 2, checking, verifying, collating and processing data, and delineation of geochemical anomalies; Stage 3, plotting a series of geochemical maps, establishing and improving the regional geochemical database for the integrated survey area of the Shiquan-Xunyang gold ore zone, and screening and verifying anomalies.

Metadata for the measured original dataset of the stream sediments in the 7 map sheets of the integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi, are shown in Table 1.

表 1 Metadata Table of Database (Dataset)Items Description Database (dataset) name The 1∶50 000 Original Measurement Dataset on Stream Sediments for 7 Map Sheets including the Raofeng Map in the Integrated Survey Area of the Shiquan-Xunyang Gold Ore Zone, Shaanxi Database (dataset) authors Tan Le, Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co. Ltd.

Zhang Yongqiang, Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co. Ltd.

Liu Xiaopeng, Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co. Ltd.

Li Xiaoming, Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co. Ltd.

Wang Caijin, Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co. Ltd.Data acquision time 2013—2018 Geographic area Shiquan-Xunyang, Shaanxi Data format *.xlsx Data size 2.01MB Data service system URL http://dcc.cgs.gov.cn Fund project China Geological Survey Project (121201004000150017-53, 121201004000160901-54, 121201004000172201-45, 12120113048100). Language Chinese Database(dataset) composition The dataset consists of 7 separate Excel sheets: Raofeng Sampling Points and Element Analytical Result Sheet, Tiefosi Sampling Points and Element Analytical Result Sheet, Hanyin Sampling Points and Element Analytical Result Sheet, Dahekou Sampling Points and Element Analytical Result Sheet, Zhaojiawan Sampling Points and Element Analytical Result Sheet, Yingfengjie Sampling Points and Element Analytical Result Sheet and Ankang Sampling Points and Element Analytical Result Sheet. 2. Field Work Methods

2.1 Selection Method

The survey area is a humid−semihumid mid-and-low hilly natural landscape area (Fan HM and Li FZ, 2013), humid, rainy, strongly denuded, deeply cut, mainly physically-weathered, where channel-system alluvium and diluvium have the properties of coarse debris, suitable for the measurement of the stream sediments (Liu JS et al., 2016). In accordance with the Specifications of the Geochemical Reconnaissance Survey (1∶50 000)(DZ/T 0011−2015), considering the geochemical landscape features of the survey area, it was decided to use stream sediment as the medium to be sampled for this geochemical reconnaissance survey, at a sampling density of 4~8 points/km2, and –20 meshes ~ +60 meshes are selected for the sample’s grain size.

2.2 Sampling

2.2.1 Sample Location

In the survey area, samples for measurement of 1∶50 000 stream sediments are all taken from the river bottom or the contact between the riverbank and the water surface (Zhang Y et al., 2018). In intermittent or trunk river channels, samples are mainly taken from the bottom of the riverbed; in rivers with rapid flow, samples are taken at places where water flows slowly or stops, or behind a boulder, or where water flow widens, or at the inner side of the turn of the river channel, where much more fine-grained materials concentrate.

2.2.2 Sampling Materials

Following the principle that sampled media shall represent material components of bedrocks containing original geological prospecting information, sampling materials are sludge, silt or fine sand in stream sediments.

2.2.3 Sampling Methods

Samples taken from the stream sediments in the survey area are graded sections, mixing coarse−fine-grain sizes, care being taken to avoid sampling from the humus layer. During sampling, an emphasis was placed on taking more samples at places where alteration−mineralization is strong, or which are priorities for prospecting. Samples are taken using the specific technique below:

① Prior to sampling, the topsoil or humus layer is removed with a sampling spoon.

② The cloth bag used for housing samples is checked to ensure that it does not have split seams or broken holes before placing samples within it. Before putting moist samples in the bag, they were placed in a plastic bag and then in the cloth bag, to prevent samples from becoming wet and contaminated, due to mutual leaching.

③ To make samples more representative, samples were taken at multiple points of 3~5 places 20~30 m within upstream and downstream of the sampling points and then combined into one sample.

④ Sampling avoids locations where there are pollutants and accumulated collapses at the bank due to mine development, villages and towns, dams, field-making from silty land, traffic route or road junctions.

2.2.4 Point Fixation in the Field

The integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi, involves seven 1∶50 000 map sheets (Table 2) in which the 1980 Xi’an coordinate system is used and the central meridian is 111°, and geological data involved in the map sheets were purchased from the Shaanxi Geographic Information Survey Bureau.

表 2 Topographic map of seven 1∶50 000 Map Sheets involved in the Integrated Survey Area of the Shiquan-Xunyang Gold Ore Zone, ShaanxiMap sheet name Map sheet number Raofeng I49E17001 Yingfengjie I49E18002 Tiefosi I49E18003 Hanyin I49E19003 Dahekou I49E19004 Zhaojiawan I49E19005 Ankang I49E02005 The 1∶50 000 standard topographic map is used as a base map for field measurement of the stream sediments to determine the sampling points in the field with a hand-held IGS-100 device (Li CL et al., 2002). Errors in point localization were less than 30 m from their actual locations, i.e. less than 1 mm on the base map.

2.3 Density of Sampling Points

During the project there were 13 169 samples in total taken from stream sediments. Based on topographic and landform characteristics, landscape conditions and geological features, for the measurement of these 1∶50 000 stream sediments, different sampling layouts and densities were used: at the densest area (i.e. referring to areas where at 1∶200 000 a geochemical anomaly is obvious, there was more information on mineralization, larger in the bedrock area and distributed with less Quaternary strata, and in addition to normal point arrangements, sampling in sections favoring metallogenesis are undertaken to the standard density), the sampling density was 5.18~5.46 points/km2; at the ordinal work area (i.e. referring to areas where there are more Quaternary strata, smaller or sporadic outcropped bedrocks, and the 1∶200 000 geochemical anomaly is weak), the sampling density was 4.1~4.3 points/km2; at the scattered area (i.e. intermountain basin), the sampling density was 3.13~3.52 points/km2. The combination of these sampling densities allows the effective control of the vast majority of water catchment within the area, which is cost-effective and enables the effective meeting of the goal of the geochemical reconnaissance survey.

2.4 Sample Processing

The basic procedure to process samples: natural drying → trituration →sieving →mixing evenly → weighing and splitting samples →fillling in the label → placing samples into bags → completing the sample delivery order → placing sampled bags into boxes (Chen YM and Chen XF, 2018).

Sample drying method: dried under sunlight and air. During drying, rub and knead samples regularly to prevent caking, and use a mallet to strike them properly,

② Dried samples were sieved with a −20~+60 mesh nylon sieve, samples under the sieve are mixed evenly through diagonal folding, split and then put into paper bags, their weight being ≥ 310 g.

③ Samples processed by sample splitting were divided into two parts, each part ≥ 150 g, one put into a kraft paper bag and sent for testing, and the other placed into plastic bottles, which were then sealed and kept as duplicate samples.

3. Sample Analysis and Testing

Samples were analyzed and tested by the Xi’an Center for Mineral Resource Supervision and Testing under the Ministry of Natural Resources and a laboratory of the Hanzhong Geological-Battalion Co., Ltd. under the Shaanxi Bureau of Geology and Mineral Resource, both of which possess Qualification A for rock and mineral testing, in strict accordance with the Additional Rules for Regulating Sample Analysis Technologies of Geochemical Reconnaissance Surveys (Scale: 1∶50 000).

3.1 Processing and Preparation of Lab Samples

Labs are provided with full-time staff to manage samples, receive, inspect and care for samples, as well as handle sample handover procedures strictly in accordance with requirements in the specifications.

The samples were coded and processed as an analytical batch of 50, each analytical batch also containing 4 randomly inserted level-1 national standard substances, the data sent to a computer to print out a comparison table showing the respective numbers of samples analyzed and those delivered, which was then used by sample management staff in tasks such as managing samples and filling in the summary tables, and samples were subsequently sent by the sample management staff to the ore-crushing room where they were crushed without contamination.

Geochemical samples must be fully dried at a temperature below 60℃ prior to processing. Before massive sample processing, debris samples should be tested for the best conditions for agate ball numbers and ball-milling time so that the particle size of the finely-ground samples meets the requirement for the 1∶50 000 regional geochemical survey, that finely-ground samples with particle size reaching –0.074 mm (–200 mesh) accounted for at least 90% of the sample.

The sample management staff checked whether each processed batch of samples met the requirement for particle size; inserted designated control samples and Level-1 national standard samples into acceptable batches as required, whilst separating inner inspection samples based on their codes and numbers, and then delivering them to quality management staff to assign analysis tasks.

3.2 Items Analyzed and Analytical Methods

According to the Project Task, Contract and General Design Specification, in 2013—2015, the items to be analyzed during the measurement of the 1∶50 000 stream sediments were the 12 elements: Au, Ag, Cu, Pb, Zn, As, Sb, Hg, V, Mo, Ti and W. In 2016—2018, the items to be analyzed for measurement of the 1∶50 000 stream sediments totalled 16 elements: Au, Ag, Cu, Pb, Zn, As, Sb, Hg, Bi, Sn, W, Mo, Cd, Co, Cr and Ni.

Instruments such as Optical Emission Spectrometer (OES), Atomic Fluorescence Spectrometer (AFS), Inductive Coupling Plasma-Mass Spectrometer (ICP-MS) and Graphite Furnace-Atomic Absorption Spectrometer (GF-AAS) were used in analysis and testing, and all elements reported percentages were 100%. Schemes for testing and analysis of the 18 elements in the survey area are shown in Table 3.

表 3 Analytical methods, detection limits and report percentages of the 18 elements in the survey areaAnalytical method Element content Specified detection limit for the 1∶50 000 geochemical measurement Detection limit of the method used Report percentage (%) GF-AAS w(Au)/10−9 0.3~1 0.23 100 F-AAS w(Cu)/10−6 2 1.00 100 w(Zn)/10−6 20 5.00 100 HG-AFS w(As)/10−6 0.5~1 0.20 100 w(Sb)/10−6 0.3 0.05 100 CV-AFS w(Hg)/10−9 10~50 2.00 100 w(Bi)/10−6 0.3 0.1 100 ICP-OES w(Ti)/10−6 100 9.3 100 w(V)/10−6 20 5 100 OES w(Ag)/10−6 0.050 0.019 100 w(Sn)/10−6 2 0.5 100 ICP-MS w(Pb)/10−6 5~10 0.91 100 w(W)/10−6 1 0.048 100 w(Mo)/10−6 1 0.056 100 w(Ni)/10−6 1 0.21 100 w(Co)/10−6 1 0.10 100 w(Cr)/10−6 10 1.00 100 w(Cd)/10−6 0.2 0.02 100 4. Description of Data Samples

The measured original dataset on the 1∶50 000 stream sediments in the 7 map sheets of the integrated survey area of the Shiquan-Xunyang gold ore zone contains data in Excel form, including 7 separate sheets: Raofeng Sampling Points and Element Analytical Result Sheet, Tiefosi Sampling Points and Element Analytical Result Sheet, Hanyin Sampling Points and Element Analytical Result Sheet, Dahekou Sampling Points and Element Analytical Result Sheet, Zhaojiawan Sampling Points and Element Analytical Result Sheet, Yingfengjie Sampling Points and Element Analytical Result Sheet, and Ankang Sampling Points and Element Analytical Result Sheet (Song XL et al., 2017). Each sheet contains the following: sample No., Gaussian coordinates, map sheet No., stratigraphy, analyzed result (elements analyzed in Tiefosi, Dahekou, Hanyin and Zhaojiawan map sheets are Au, Hg, Ag, Cu, Pb, Zn, Mo, As, Sb, Ti, V and W; elements analyzed in Yingfengjie, Raofeng and Ankang map sheets are Au, Ag, Cu, Pb, Zn, As, Sb, Hg, Bi, Sn, W, Mo, Cd, Co, Cr and Ni) and remarks. Dataset structure could be seen in Table 4.

表 4 Dataset structure of the measured original data of the stream sediments in the integrated survey area of the Shiquan-Xunyang gold ore zone, ShaanxiNo. Name of data item Dimension Data category Field length Real example 1 Sample No. Character type 20 57C2 2 Map sheet No. Character type 20 I49E018002 3 Stratigraphy Character type 20 O3−S1b 4 Gauss horizontal coordinate Character type 20 255460 5 Gauss vertical coordinate Character type 20 3672075 6 Longitude Character type 20 108°22′45″ 7 Latitude Character type 20 33°08′48″ 8 Au 10−9 Floating-point type 20 1.03 9 Ag 10−6 Floating-point type 20 42 10 Cu 10−6 Floating-point type 20 35.9 11 Pb 10−6 Floating-point type 20 35.9 12 Zn 10−6 Floating-point type 20 83.7 13 As 10−6 Floating-point type 20 3.88 14 Sb 10−6 Floating-point type 20 2.13 15 Hg 10−9 Floating-point type 20 49 16 Bi 10−6 Floating-point type 20 0.85 17 Sn 10−6 Floating-point type 20 3 18 W 10−6 Floating-point type 20 2.14 19 Mo 10−6 Floating-point type 20 0.93 20 Cd 10−6 Floating-point type 20 0.1 21 Co 10−6 Floating-point type 20 22.3 22 Cr 10−6 Floating-point type 20 94.6 23 Ni 10−6 Floating-point type 20 41.9 24 Ti 10−6 Floating-point type 20 25 V 10−6 Floating-point type 20 5. Data Quality and Assessment

5.1 Quality of the Original Data

In the process of analyzing and testing geochemical samples in the Tiefosi, Hanyin, Dahekou and Zhaojiawan map sheets, every 50 samples were grouped to be coded and processed as one analytical batch, each analytical batch being randomly inserted with 4 Level-1 national standard substances which were GBW07302a, GBW07304a, GBW07309 and GBW07318, in order to monitor and control the precision of the analytical process. In addition, 12 Level-1 national standard substances are added randomly in sections (once for every 500 samples) for 15 times in total, to monitor the accuracy of the analytical process, and some high and low values of samples were randomly inspected and analyzed, with 2.6% of samples receiving random inspection.

In the process of analyzing and testing geochemical samples in the Raofeng, Yingfengjie and Ankang map sheets, every 50 samples were grouped to be coded and processed as one analytical batch, 243 batches in total. Each analytical batch is randomly inserted with 4 Level-1 national standard substances purchased from the CAGS Geophysical & Geochemical Exploration Institute, in order to monitor and control the accuracy of the analytical process. Of these, to analyze the 8 elements Au, Ag, Hg, Pb, Sn, As, Sb and Bi, GSD-10, GSD-14, GSD-18 and GSD-20 were inserted to control the precision of the analytical process; to analyze the other 8 elements Cr, Co, Ni, Cu, Zn, Mo, Cd and W, GSD-8a, GSD-9, GSD-10 and GSD-14 were inserted to control the precision of the analytical process, and some high and low values of samples were randomly inspected and analyzed, with 1.4 % of samples receiving random inspection.

During this detection, the qualifying rate of element inner examination (duplicate sample) was more than 95.00%; all elements’ report percentages were 100%; the qualifying rate of element anomaly re-examination was at least 97.5%; the detection limits of analytical methods used all met the standard requirement on 1∶50 000 geochemical samples in DZ/T0130.4−2006. Precision of methods: the mean ΔlgC detected with Level-1 national standard substance was within –0.099~+0.099. Accuracy of methods: the mean ΔlgC detected with Level-1 national standard substance was within –0.099~+0.099. The detection limit, precision and accuracy of the analytical methods selected met the quality-related requirements in the Additional Rules for Regulating Sample Analysis Technologies of Geochemical Reconnaissance Surveys (Scale 1∶50 000).

Above-mentioned figures concerning quality-related parameters indicate that this examination fully complied with the quality-related requirements in the Additional Rules for Regulating Sample Analysis Technologies of Geochemical Reconnaissance Surveys (Scale 1∶50 000) and DZ0130.4−2006.

5.2 Quality in Establishing the Resulting Database

The measured results database of the 1∶50 000 stream sediments in the 7 map sheets including Raofeng on the integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi (Wan CX et al., 2009), was set up in accordance with the geochemical data model by using the software platform DGSS (Pang JF et al., 2017), properties and structures of all the elements analysed were completed by referring to the content and structure of the CGS’s solid mineral survey database (Zuo QC et al., 2018; Li CL et al., 2013), to ensure that the data structure and content were complete and sound. The generated measurement databases of 1∶50 000 stream sediments in the 7 map sheets have been reviewed and accepted by the experts from the Xi'an Center of China Geological Survey and the Development and Research Center of China Geological Survey, scoring 93, awarded “Excellence”, and have thus been handed over.

6. Conclusions

The scope of the work area involved in this database was the measurement of the 1∶50 000 stream sediments in the 7 map sheets including Raofeng in the integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi, organized and implemented by the Xi'an Center and the Development and Research Center of China Geological Survey, covering 3 010 km2. It is the first time that unified sampling, analytical and testing methods have been used to analyze elements in a systematic way in the integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi. It is also the first time that a geochemical databases have been established in a standardized way in the integrated survey area, so as to obtain valuable first-hand geochemical measurement information.

With the results from the database, 10 Au prospecting target areas and 12 Au prospective areas were delineated in the integrated survey area❶, and at the newly-discovered Bawanggou Au deposit from the Au-delineated prospecting target area at and around Shuanghekou, Hanyin County, Shaanxi, with a subsequent provincial fund for geological exploration, it was found that the Au resource (333+334) was 30 tons; in the Au-prospecting target area at and around Jiangjunshan, Ankang city, Shaanxi, the Zaoyang Au deposit was recently found, and a subsequent provincial fund created for geological exploration, the Au (333+334) resource is 20 tons. In addition, 4 new gold ore occurrences were discovered in Shaanxi by using the results from this database, and they are located in Yangou, Ningshan County; Liukeng, Hanbin District, Ankang City; Shiqiao and Zhanfang, Shiquan County, all of which have a certain prospecting potential. Furthermore, the results from the database have guided Shaanxi to find 2–4 new large-scale Au resource development bases.

Notes:

❶ Zhang Yongqiang, Sun Jian, Tan Le. 2018. Comprehensive result report of sub-projects from 2016 to 2018 on mineral investigation and prospecting prediction in the integrated survey area of the Shiquan-Xunyang gold ore zone, Shaanxi[R]. Ankang: Team No.1, Shaanxi Bureau of Geology and Mineral Resources Co.Ltd., Ankang, Shaanxi, 1−260 (in Chinese).

致谢: 非常感谢郝梓国研究员在文章多次修改过程中的交流和启发,感谢周红军教授级高级工程师在审稿中提出的宝贵意见。 -

图 3 大直径加重管组合绳索取心钻具结构(据朱恒银等,2016b)

1—钻头;2—下扩孔器;3—外管;4—上扩孔器;5—短节;6—卡簧座;7—卡簧;8—内管;9—内管单动岩心打捞装置;10—加重管;11—下扶正器;12—加重管;13—上扶正器;14—过渡加重管;15—过渡加重管扶正器;16—绳索取心钻杆

Figure 3. Structure of combined large-diameter wire line drilling tool with a heavy pipe (after Zhu Hengyin et al., 2016b)

1-Drill bit; 2-Lower reamer; 3-Outer tube; 4-Upper reamer; 5-Barrel nipple; 6-Circlip seat; 7-Circlip; 8-Inner barrel; 9-Core fisher; 10-Heavy weight pipe; 11-Lower centralizer; 12-Heavy weight pipe; 13-Upper centralizer; 14-Extra heavy weight pipe; 15- Extra centralizer; 16-Wire line core drill pipe

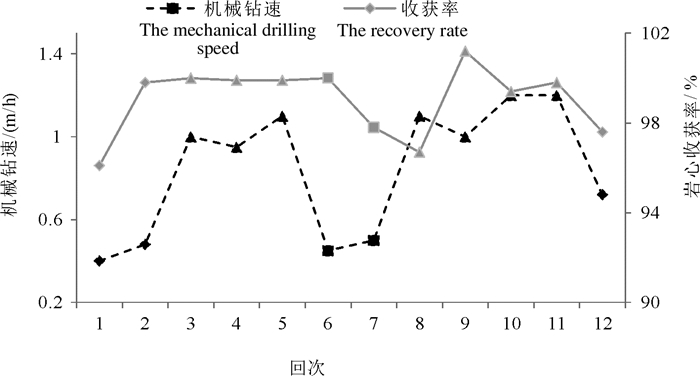

图 5 3种钻具机械钻速和岩心收获率对比(据朱芝同等,2019)

◆—川7-4;▲—KT-194;■—密闭取心钻具

Figure 5. Comparison of mechanical drilling speed and core recovery rate of three drilling tools(after Zhu Zhitong et al., 2019)

◆-Chuan 7-4; ▲-KT-194; ■-Closed coring drilling tool

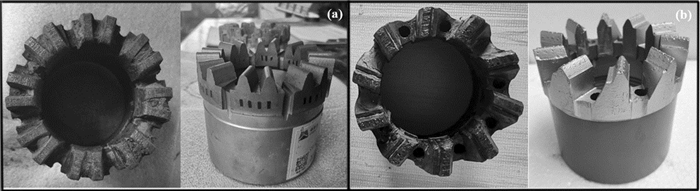

图 8 常规硬岩齿轮钻头和高胎体偏心斜齿孕镶金刚石钻头(设计钻头)取心效率对比

a—泥岩层取心效率对比;b—灰岩层取心效率对比

Figure 8. Comparison of coring efficiency between conventional hard rock gear bit and high matrix eccentric helical impregnated diamond bit (design bit)

a-Comparison of coring efficiency of mudstone layer; b-Comparison of coring efficiency of limestone layer

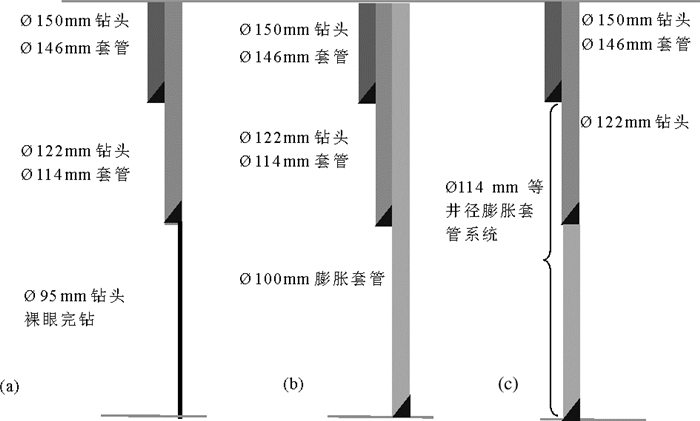

图 9 三种井身结构设计对比——以某小口径页岩气基础地质调查井为例

a—常规井身结构;b—膨胀套管井身结构;c—等井径膨胀套管结构

Figure 9. Comparison of three well structure——Taking a small-diameter shale gas basic geological survey well as an example

a-Conventional wellbore structure; b-Expansion casing wellbore structure; c-Equal well diameter expansion casing structure

表 1 中国地质调查局部署实施的典型页岩气井概况

Table 1 Overview of typical shale gas wells deployed and implemented by China Geological Survey

表 2 页岩气基础地质调查井与常规油气探井对比

Table 2 Comparison between geological survey drilling for shale gas and drilling for oil and gas

表 3 页岩气地质调查井常用钻机及其能力

Table 3 Performance of drilling rigs for shale gas geological survey

表 4 小口径页岩气井用钻井液固控循环系统主要部件

Table 4 Main components of drilling fluid solid control system for slim hole shale gas well

表 5 页岩气钻井钻井液体系特性(据单文军等,2016 a, b;郭军等,2021)

Table 5 Drilling fluid system for shale gas drilling(after Shan Wenjun et al., 2016 a, b; Guo Jun et al., 2021)

-

Bai Jing, Xu Xingyou, Chen Shan, Liu Weibin, Liu Chang, Zhang Changsheng. 2020. Sedimentary characteristics and paleo-environment restoration of the first member of Qingshankou Formation in Qian'an area, Changling sag, Songliao Basin: A case study of Jiyeyou 1 Well[J]. Geology in China, 47(1): 220-235 (in Chinese with English abstract).

Cao Longlong, Zhang Hengchun, Wang Wenshi, Yan Jia, Hu Chen. 2021. CFD simulation of the two phase flow field in the sealed coring bit[J]. Drilling Engineering, 48(11): 35-41 (in Chinese with English abstract).

Chen Xianglin, Yuan Kun, Lin Tuo, Jin Chunshuang, Kang Haixia. 2021. Discovery of shale gas within Upper Paleozoic marine facies by Qian Shuidi-1 well in the northwest of Yaziluo rift trough, Sichuan Province[J]. Geology in China, 48(2): 661-662 (in Chinese with English abstract).

Chen Xiaohong, Wang Chuanshang, Liu An, Luo Shengyuan, Li Hai, Wei Kai. 2017. The discovery of the shale gas in the Cambrian Shuijingtuo Formation of Yichang area, Hubei Province[J]. Geology in China, 44 (1): 188-189 (in Chinese with English abstract).

Chen Xiaohong, Zhang Baomin, Zhang Guotao, Chen Lin, Zhang Miao, Li Peijun. 2018. High shale gas industry flow obtained from the Ordovician Wufeng Formation and the Silurian Longmaxi Formation of Yichang area, Hubei Province[J]. Geology in China, 45 (1): 199-200 (in Chinese with English abstract).

Cheng Wan, Sun Jiaying, Yin Dezhan, Jiang Guosheng. 2021. Research status of the wellbore failure mechanism and predicting model in deep mudstone and shale[J]. Drilling Engineering, 48(10): 21-28 (in Chinese with English abstract).

Chi Huanpeng, Hu Zhifang, Wang Shengjian, Li Dayong, Yuan Kun, Guo Jun. 2021. Drilling techniques for thief zones in surface formations in western Guizhou[J]. Drilling Engineering, 48(4): 66-72 (in Chinese with English abstract).

Ding Tao. 2018. The Design of the Shale Gas Investigation Well Control System[D]. Beijing: China University of Geosciences (Beijing): (in Chinese with English abstract).

Fan Lasheng, Liu Wei, Zhang Tongde, Deng Wei, Lu Junze. 2021. Drilling of a large diameter geological survey well (Well Chuanmudi-2) in Muchuan county of Sichuan Province[J]. Drilling Engineering, 48(12): 43-53 (in Chinese with English abstract).

Feng Meigui, Weng Wei, Liu Jiarong, Li Chao, Jiang Rui, Zhao Zhitao, Liu Wenwu, Ouyang Zhiyong, Xu Junjun, Guo Kun, He Yunchao. 2020. Drilling fluid solid control circulation system for drilling of geothermal exploration and production well D20 in Xiong'an New Area[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 47(10): 38-42, 60 (in Chinese with English abstract).

Fu Cong, Ding Hu, Chen Wenmin. 2021. Research on exploration and development layout of shale gas with policy support in China's Yangtze River economic belt[J]. Coal Quality Technology, 36(6): 13-21 (in Chinese with English abstract).

Fu Xiaodong, Chen Yana, Luo Bing, Li Wenzheng, Zhang Jianyong, Wang Xiaofang, Qiu Yuchao, Lü Xueju, Yao Qianying. 2021. Characteristics and petroleum geological significance of the high-quality source rocks in the Gufeng Member of the Middle Permian Maokou Formation in the northern Sichuan basin[J]. Acta Geologica Sinica, 95(6): 1903-1920 (in Chinese with English abstract). doi: 10.3969/j.issn.0001-5717.2021.06.016

Gan Xin. 2021. Advances in vibration impactors for drilling acceleration[J]. Drilling Engineering, 48(2): 85-93(in Chinese with English abstract).

Gao Deli. 2021. Some research advances in well engineering technology for unconventional hydrocarbon[J]. Natural Gas Industry, 41(8): 153-162 (in Chinese with English abstract). doi: 10.3787/j.issn.1000-0976.2021.08.014

Gao Peng, Li Zhao, Li Shizhen, Zhou Zhi, Wei Siyu, Zhang Hongda. 2021. High-quality source rocks of marine-continental transitional facies discovered by borehole WFD-1 in the Fuyang area of Anhui Province[J]. Geology in China, 48(5): 1659-1660 (in Chinese with English abstract).

Gao Peng, Lin Tuo, Yuan Kun, Jin Chunshuang, Chen Xianglin, Wang Wenbin. 2022. Carboniferous shale gas obtained by well QND-1 in the northwest of Yadu-Ziyun-Luodian Aulacogen[J]. Geology in China, 49(4): 1348-1349 (in Chinese with English abstract).

Guo Jun, Chen Xianglin, Zhao Xunlin, Wang Wenbin, Li Yan, Han Fei. 2021. Key drilling technologies for well Qianshuidi-1 in Guizhong-Nanpanjiang area[J]. Fault-Block Oil & Gas Field, 28(3): 423-427 (in Chinese with English abstract).

Guo Jun, Wang Chaoji, Li Yan, Yuan kun, Wang Wenbin. 2020. Application of simultaneous casing drilling to large bore shale gas well drilling in shallow complex formation: A case of conductor drilling for the Qianshuidi-1 well[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 47(5): 22-26 (in Chinese with English abstract).

Hao Haiyang, Song Jiwei, Jiang Guosheng, Du Shengjiang, Li Yong, Ban Jinpeng, Huang Mingyong, Chang Limin. 2019. Drilling technology of well qianpudi-1 for basic geological survey of shale gas in Southern China[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 46(8): 23-29 (in Chinese with English abstract).

Hou Ting, Ning Xuetao, Wang Bin, Wu Liugen. 2015. Application research of expandable casing technology in drilling and well completion engineering[J]. Sino-Global Energy, 20(6): 48-51(in Chinese with English abstract).

Hou Zixu, Jia Xiaobin, Li Shuanggui, Deng Wenliang, Zeng Dezhi. 2013. Research on the torsion impact generator for speeding up drilling in deep formation of Yubei area[J]. Oil Drilling & Production Technology, 35(5): 132-136 (in Chinese with English abstract). doi: 10.3969/j.issn.1000-7393.2013.05.038

Huang Shenghui, Kui Zhong, Wu Jinsheng, Zhao Yuangang, Fang Xin. 2019. Drilling and incident treatment for well Xiangyongdi-1[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 46(2): 23-29 (in Chinese with English abstract).

Li Haohan, Du Jiang, Chen Ke, Li Fei, Song Teng, Wang Peng. 2020. The discovery of Permian shale gas in Wufeng area, Hubei Province[J]. Geology in China, 47(6): 1932-1933(in Chinese with English abstract).

Li Juan, Wang Yufang, Zhai Gangyi, Zhang Jiazheng. 2021. First drilling of shale gas within the Niutitang Formation in the Nanzheng area, Shaanxi Province[J]. Geology in China, 48(1): 337-338 (in Chinese with English abstract).

Li Shizhen, Zhou Zhi, Nie Haikuan, Zhang Leifu, Song Teng, Liu Weibin, Li Haohan, Xu Qiuchen, Wei Siyu, Tao Shu. 2022. Distribution characteristics, exploration and development, geological theories research progress and exploration directions of shale gas in China[J]. China Geology, 5(1): 110-135.

Li Xiaoyang, Li Kuan, Zhang Yongqin, Liang Jian, Wu Jixiu, Wang Zhigang. 2019. Experiment on a new turbine torsional impactor[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 46(12): 40-43, 49 (in Chinese with English abstract).

Li Yan, Guo Jun, Wang Wenbin. 2021. Drilling difficulties and solutions for well Yunxuandi-1 for shale gas survey in eastern Yunnan[J]. Drilling Engineering, 48(8): 12-18 (in Chinese with English abstract).

Liao Shengbing, Shi Gang, Li Jianqing, Zheng Hongjun, Zhou Daorong, Wang Cunzhi, Huang Ning. 2021. Shale gas drilled by well WWD1 in the Wangjiang area of Anhui Province[J]. Geology in China, 48(5): 1657-1658 (in Chinese with English abstract).

Liu Bing, Zhu Hengyin, Cai Zhengshui, Wang Qiang, Lu Wencheng. 2020. Key drilling technology for complex working conditions in Ningguo Depression[J]. Science Technology and Engineering, 20(22): 8943-8947 (in Chinese with English abstract). doi: 10.3969/j.issn.1671-1815.2020.22.013

Liu Xiaoao, Zou Deyong, Chen Xiuping. 2017. Optimum design experiment of rock-breaking mechanism of polycrystalline diamond compact-diamond impregnated matrix bit for drilling hard and strong abrasive formation[J]. Science Technology and Engineering, 17(29): 220-226 (in Chinese with English abstract). doi: 10.3969/j.issn.1671-1815.2017.29.032

Liu Xielu, Ruan Hailong, Zhao Yi, Cai Jiapin, Chen Yunlong, Liang Tao, Li Chun, Liu Hailong, Deng Dudu. 2021. Progress in research and application of the pressure-temperature core sampler for marine natural gas hydrate[J]. Drilling Engineering, 48(7): 33-39 (in Chinese with English abstract).

Liu Zhi. 2017. Application Analysis on small diameter core drilling technology in shale gas geological exploration well[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 44(9): 32-37 (in Chinese with English abstract). doi: 10.3969/j.issn.1672-7428.2017.09.007

Ma Tianshou, Chen Yingjie, Duan Mubai. 2018. Chemo-poroelastic coupling method for wellbore stability analysis in shale gas formation with weakness planes[J]. Geotechnical and Geological Engineering, 36(3): 1817-1831. doi: 10.1007/s10706-017-0434-2

Pang Fei, Zhang Zuoheng, Zhang Junfeng, Chen Ke, Shi Dishi, Bao Shujing, Li Shizhen, Guo Tianxu. 2020. Progress and prospect on exploration and development of shale gas in the Yangtze River economic belt[J]. Earth Science, 45(6): 2152-2159 (in Chinese with English abstract).

Peng Cancan, Li Fenqiang, Wu Cong, Wei Youlin. 2013. Shale gas parameter well slim hole drilling technology——A case study of Changye No. 1 Well[J]. Coal Geology of China, 25(11): 55-58 (in Chinese with English abstract). doi: 10.3969/j.issn.1674-1803.2013.11.12

Peng Fenfei, Wang Jialiang, Wan Buyan, Huang Xiaojun, Tang Yonghui, Peng Deping. 2021. Design of the pressure-coring tool for underwater drilling rig[J]. Drilling Engineering, 48(4): 97-103 (in Chinese with English abstract).

Qi Liefeng. 2016. The Design of New Type of Hydraulic Torsion Impactor and its Dynamic Simulation[D]. Jinzhou: Yangtze University (in Chinese with English abstract).

Qin Yinglun, Zhang Jiazheng, Wang Yufang, Kang Haixia, Li Juan, Zhang Ziya, Xue Zong'an, Zhang Yunxiao. 2020. Discovery of shale gas by Guirongye-1 well within Carboniferous Luzhai Formation in Guizhong depression, Guangxi[J]. Geology in China, 48(2): 667-668(in Chinese with English abstract).

Shan Wenjun, Duan Xiaoqing, Ren Fujian, Zhang Weihua, Yue Weimin, Li Yanning. 2016a. Application of low solid film-forming system in well"Wuye-1"in Wuwei Basin of Gansu[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 43(7): 111-115 (in Chinese with English abstract).

Shan Wenjun, Jiang Rui, Tao Shixian, Yue Weimin, Li Yanning. 2016b. Research and application of the flushing fluid system for shale gas drilling[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 43(10): 176-181 (in Chinese with English abstract).

Shi Gang, Li Jianqing, Liao Shengbing, Wu Tong, Huang Ning, Fang Chaogang, Huang Zhengqing, Shao Wei, Ye Jun, Cai Xiaohu, Zhang Qiang. 2021. Discovery of Permian shale gas in the Wanyoudi-1 well of Xuancheng, Anhui Province[J]. Geology in China, 48(2): 669-670.

Song Teng, Chen Ke, Bao Shujing, Guo Tianxu, Lei Yuxue, Wang Yi, Meng Fanyang, Wang Peng. 2018. The discovery of shale gas in Wufeng-Longmaxi Formation at Hongdi-1 Well on the northern limb of Shennongjia anticline in northwestern Hubei Province[J]. Geology in China, 45(1): 195-196 (in Chinese with English abstract).

Su Zhou, Zhang Shaohe, Wang Wenbin, Cao Han, Liu Leilei, Xiao Jincheng, He Hongsheng, Guo Jun. 2021. Technical difficulties in drilling of well Qianshuidi-1 and their solutions[J]. Drilling Engineering, 48(5): 54-59(in Chinese with English abstract).

Teng Long, Fang Chaogang, Zheng Hongjun, Zhai Gangyi, Li Jianqing, Huang Zhengqing, Wang Jingdong, Zhang Hao, Lü Xing. 2019. The discovery of 'three natural gases' in the Upper Permian Leping Formation in Ganfengdi-1 well of middle Pingle depression[J]. Geology in China, 46 (1): 203-204 (in Chinese with English abstract).

Wang Bin, Li Jun, Zou Deyong, Yang Hongwei, Huang Tao. 2018a. Mechanisms and distribution pattern of abrasions on PDC bits for highly-abrasive hard-rock[J]. Special Oil and Gas Reservoir, 25(4): 149-153(in Chinese with English abstract).

Wang Bin, Li Jun, Zou Deyong, Yang Hongwei, Wang Kai. 2018b. Design and application of a PDC hybrid drill bit with impregnated diamond insert for the hard formation with strong abrasivity[J]. Special Oil and Gas Reservoir, 25(1): 169-174 (in Chinese with English abstract).

Wang Hongxi. 2018. Structural Design and Parameters Optimization Research of Rotary Torsional Impact Generator[D]. Qingdao: China University of Petroleum (East China) (in Chinese with English abstract).

Wang Jie. 2015. Design and Flow Simulation of Double Torsion Impactor for Drilling[D]. Beijing: China University of Geosciences (in Chinese with English abstract).

Wu Liugen, Ning Xuetao, Tang Ming. 2013. Emergency application of monohole expandable casing technology[J]. Drilling & Production Technology, 36(6): 1-4 (in Chinese with English abstract).

Wu Xiaolong, Zhu Zhitong, Dong Xiangyu, Li Wenxiu. 2019. Problems and field cases of small-diameter oil and gas geological survey wells[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 46(9): 27-32 (in Chinese with English abstract).

Xiong Hulin, Zhang Fei, Gan Huimin, Xu Longsheng. 2019. Coring technique for shale gas survey Quancan well-1[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 46(6): 19-25 (in Chinese with English abstract).

Xu Yunlong, Wang Rui, Wang Wenfei, Liu Jiangang. 2014. High quality and high speed drilling technology for ultra-deep five-section sidetracking horizontal well TP131HCH[J]. Drilling Engineering, 41(10): 22-25. doi: 10.3969/j.issn.1672-7428.2014.10.006

Yang Shunhui, Wu Haojie, Niu Chengcheng, Hou Xutian, Jin Junbin. 2014. Manufacture and application of PDC bit enhanced by special Diamond-impregnated segment[J]. Petroleum Drilling Techniques, 42(6): 111-114 (in Chinese with English abstract).

Yang Xianyu, Cai Jihua, Jiang Guosheng, Shi Yanping. Chen Shuya, Wei Zhaohui, Xie Zhangjian. 2021. Physical plugging simulation and chemical inhibition experiment for wellbore stability in shale[J]. Drilling Engineering, 48(4): 37-46 (in Chinese with English abstract).

Yu Jinpin, Zou Deyong, Liu Xiaoao. 2020. Design and application of novel hybrid drill bit for hard formation with strong abrasivity[J]. Dimaond & Abrasives Engineering, 40(3): 67-71 (in Chinese with English abstract).

Yuan Kun, Wang Chao, Qin Yinglun, Yu Shufang, Chen Rong, Shi Dishi, Bao Shujing, Lin Tuo, Zhou Zhi. 2017. The discovery of Carboniferous shale gas in Qianziye-1 well of Qianan (southern Guizhou) depression[J]. Geology in China, 44(6): 1253-1254(in Chinese with English abstract).

Zhai Gangyi, Bao Shujing, Pang Fei, Ren Shoumai, Chen Ke, Wang Yufang, Zhou Zhi, Wang Shengjian. 2017. Peservoir-forming pattern of "four-storey" hydrocarbon accumulation in Anchang syncline of northern Guizhou Province[J]. Geology in China, 44(1): 1-12(in Chinese with English abstract).

Zhai Gangyi, Wang Yufang, Zhou Zhi, Yu Shufang, Chen Xianglin, Zhang Yunxiao. 2018. Exploration and research progress of shale gas in China[J]. China Geology, 1: 257-272. doi: 10.31035/cg2018024

Zhang Baomin, Cai Quansheng, Chen Xiaohong, Wang Chuanshang, Zhang Guotao, Chen Lin, Li Peijun, Li Yangui. 2021. Reservoir characteristics and gas-bearing capacity of the Wufeng-Longmaxi Formation in the Well Eyy2, east Huangling Uplift, western Hubei Province[J]. Geology in China, 48(5): 1485-1498(in Chinese with English abstract).

Zhang Delong, Weng Wei, Jia Jun, Huang Yuwen, Feng Meigui. 2015. Well control techniques in hot dry rock drilling[J]. Science & Technology Review, 33(19): 45-48(in Chinese with English abstract).

Zhang Fu, Huang Yi, Lan Baofeng, Li Long, Liu Ting, Liu Rui, Jiang Dingchuan. 2021. Characteristics and controlling factors of shale reservoir in Wufeng Formation-Longmaxi Formation of the Zheng'an area[J]. Bulletin of Geological Science and Technology, 40(1): 49-56(in Chinese with English abstract).

Zhang Hengchun, Wang Wenshi, Li Kuan, Wang Yuewei, Yan Jia, Cao Longlong, Hu Chen. 2021. Application of the KT178 core tool in Gonghe hot dry rock exploratory wells[J]. Drilling Engineering, 48(2): 29-34(in Chinese with English abstract).

Zhang Junfeng, Zhai Gangyi, Wang Daming, Bao Shujing, Chen Ke, Li Haohan, Songteng, Wang Peng, Zhou Zhi. 2020. Tectonic evolution of the Huangling dome and its control effect on shale gas preservation in the north margin of the Yangtze Block, South China[J]. China Geology, 3: 28-37. doi: 10.31035/cg2020025

Zhang Wenhao, Gao Yongjin, Zhou Xingui, Zhai Gangyi, Xu Xingyou, Bai Zhongkai, Zhou Zhi, Bi Caiqin, Shan Yansheng, Han Miao, Sun Xiangcan, Zhang Yuanyin, Liu Weibin. 2021. The new prospecting and direction of nonprofit petroleum basic geological survey in China[J]. Acta Geologica Sinica, 95(5): 1630-1643 (in Chinese with English abstract). doi: 10.3969/j.issn.0001-5717.2021.05.023

Zhang Ziya, Zhang Cong, Shi Dishi, Qin Yinglun, Chen Rong, Kang Haixia. 2019. Important discovery of Devonian natural gas in Yunningdi 1 Well of Ninglang-Yanyuan area[J]. Geology in China, 46(2): 432-433 (in Chinese with English abstract).

Zhao Hongbo, Shan Wenjun, Zhu Disi, Yue Weimin, He Yuanxin. 2021. Advance of fractured formation lost circulation mechanism and lost circulation materials in oil and gas wells: A review[J]. Oilfield Chemistry, 38(4): 740-746 (in Chinese with English abstract).

Zhao Hongbo, Zhu Disi, Huang Zheng, Wang Shengjian, He Yuanxin. 2020. Shale gas drilling technology in southern north China basin Bozhou-Fuyang[J]. Oil Drilling & Production Technology, 42(6): 679-683 (in Chinese with English abstract).

Zhao Liping, Wang Qian, Guo Zheng, Fang Chao, Cao Hu. 2020. Stability evaluation for wellbore in layered shale formation based on limited collapse width[J]. Science & Technology Review, 38(11): 122-130 (in Chinese with English abstract).

Zhao Wenzhi, Jia Ailin, Wei Yunsheng, Wang Junlei, Zhu Hanqing. 2020. Progress in shale gas exploration in China and prospects for future development[J]. China Petroleum Exploration, 25(1): 31-44 (in Chinese with English abstract). doi: 10.3969/j.issn.1672-7703.2020.01.004

Zhao Yuangang, Wu Lin, Shi Shaoyun, Qian Feng, Huang Shenghui, Huang Xiaolin. 2021. Innovation research and practice on the management mode for separate budget drilling projects in geological survey[J]. Drilling Engineering, 48(4): 54-59 (in Chinese with English abstract).

Zheng Hongjun, Zhou Daorong, Yin Qichun, Xiong Qiangqing, Wang Zhongpeng, Fang Chaogang, Teng Long, Shao Wei, Wang Yuanjun. 2020. New progress and breakthrough difficulties on shale gas geological survey in the lower Yangtze area[J]. Journal of Geomechanics, 26(6): 852-871 (in Chinese with English abstract).

Zhou Zhi, Bao Shujing, Chen Ke, Xu Qiufeng, Zhang Shousong, Wang Chao, Wang Peng. 2018. An important discovery of shale gas in Permian formation of Jianshi area, Hubei Province[J]. Geology in China, 45(6): 1304-1305 (in Chinese with English abstract).

Zhou Zhi, Li Shizhen, Chen Ke, Li Haohan, Li Fei, Xu Guihong. 2020. The discovery of shale gas in Silurian strata in Zigui, Hubei Province[J]. Geology in China, 47(3): 881-882(in Chinese with English abstract).

Zhu Disi, Yue Weimin, Shan Wenjun, Zhao Hongbo, Weng Wei. 2020. Drilling technology for well Zhetongdi-1 for shale gas geological survey[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 47(9): 15-20 (in Chinese with English abstract).

Zhu Hengyin, Wang Qiang, Tian Bo, Wang Jiuquan. 2016a. Research and application of a combined large-diameter wireline drilling tool with a heavier pipe[J]. Geology and Exploration, 52(6): 1159-1166 (in Chinese with English abstract).

Zhu Hengyin, Wang Qiang, Zhang Zheng, Cai Zhengshui. 2016b. Application research on large diameter weighted combined wire-line coring technology for shale gas exploration[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 43(10): 160-164 (in Chinese with English abstract).

Zhu Hengyin, Wang Qiang. 2013. A summary of exploration and development techniques of shale gas[J]. Geology of Anhui, 23(1): 21-25 (in Chinese with English abstract). doi: 10.3969/j.issn.1005-6157.2013.01.005

Zhu Yongyi, Wang Wenshi, Zhang Hengchun, Yan Jia, Cao Longlong, Xu Jie, Meng Qinghong, Tan Xiaoli. 2018. Implementation overview of Chinese Continental Scientific Drilling(CSCD)project and technical systems of core boring[J]. Acta Geologica Sinica, 92(10): 1971-1984 (in Chinese with English abstract). doi: 10.3969/j.issn.0001-5717.2018.10.001

Zhu Zhitong, Wu Xiaolong, Dong Xiangyu, Cao Longlong, He Guolei, Zhang Dejun. 2019. Large diameter coring technology for shale oil exploration in Songliao Basin[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 46(1): 45-50 (in Chinese with English abstract).

白静, 徐兴友, 陈珊, 刘卫彬, 刘畅, 张昌盛. 2020. 松辽盆地长岭凹陷乾安地区青山口组一段沉积相特征与古环境恢复——以吉页油1井为例[J]. 中国地质, 47(1): 220-235. http://geochina.cgs.gov.cn/geochina/article/abstract/20200118?st=search 曹龙龙, 张恒春, 王稳石, 闫家, 胡晨. 2021. 密闭取心钻头两相流流场CFD模拟研究[J]. 钻探工程, 48(11): 35-41. 陈相霖, 苑坤, 林拓, 金春爽, 康海霞. 2021. 四川垭紫罗裂陷槽西北缘(黔水地1井)发现上古生界海相页岩气[J]. 中国地质, 48(2): 661-662. http://geochina.cgs.gov.cn/geochina/article/abstract/20210222?st=search 陈孝红, 王传尚, 刘安, 罗胜元, 李海, 危凯. 2017. 湖北宜昌地区寒武系水井沱组探获页岩气[J]. 中国地质, 44 (1): 188-189. http://geochina.cgs.gov.cn/geochina/article/abstract/20170113?st=search 陈孝红, 张保民, 张国涛, 陈林, 张淼, 李培军. 2018. 湖北宜昌地区奥陶系五峰组-志留系龙马溪组获页岩气高产工业气流[J]. 中国地质, 45 (1): 199-200. http://geochina.cgs.gov.cn/geochina/article/abstract/20180119?st=search 程万, 孙家应, 尹德战, 蒋国盛. 2021. 深层泥页岩井壁失稳机理与预测模型研究进展[J]. 钻探工程, 48(10): 21-28. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202110003.htm 迟焕鹏, 胡志方, 王胜建, 李大勇, 苑坤, 郭军. 2021. 黔西地区表层易漏地层钻井工程技术[J]. 钻探工程, 48(4): 66-72. 丁涛. 2018. 页岩气调查井井控系统设计[D]. 北京: 中国地质大学(北京). 樊腊生, 刘伟, 张统得, 邓伟, 陆俊泽. 2021. 四川沐川大口径地质调查井(川沐地2井)钻探施工技术[J]. 钻探工程, 48(12): 43-53. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202112008.htm 冯美贵, 翁炜, 刘家荣, 李超, 蒋睿, 赵志涛, 刘文武, 欧阳志勇, 徐军军, 郭坤, 贺云超. 2020. 雄安新区地热D20井钻井液固控循环系统应用分析[J]. 探矿工程(岩土钻掘工程), 47(4): 38-42, 60. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202010007.htm 付小东, 陈娅娜, 罗冰, 李文正, 张建勇, 王小芳, 邱玉超, 吕学菊, 姚倩颖. 2021. 四川盆地北部中二叠统茅口组孤峰段优质烃源岩特征及其油气地质意义[J]. 地质学报, 95(6): 1903-1920. doi: 10.3969/j.issn.0001-5717.2021.06.016 傅丛, 丁华, 陈文敏. 2021. 我国长江经济带页岩气勘探开发布局与政策探析[J]. 煤质技术, 36(6): 13-21. 甘心. 2021. 钻井提速用振动冲击工具研究进展[J]. 钻探工程, 48(2): 85-93. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202102012.htm 高德利. 2021. 非常规油气井工程技术若干研究进展[J]. 天然气工业, 41(8): 153-162. doi: 10.3787/j.issn.1000-0976.2021.08.014 高堋, 李昭, 李世臻, 周志, 魏思宇, 张宏达. 2021. 安徽阜阳地区皖阜地1井钻获海陆过渡相高品质烃源岩[J]. 中国地质, 48(5): 1659-1660. http://geochina.cgs.gov.cn/geochina/article/abstract/20210527?st=search 高堋, 林拓, 苑坤, 金春爽, 陈相霖, 王文彬. 2022. 垭紫罗裂陷槽西北缘黔宁地1井钻获石炭系页岩气[J]. 中国地质, 49(4): 1348-1349. http://geochina.cgs.gov.cn/geochina/article/abstract/20220423?st=search 郭军, 陈相霖, 赵训林, 王文彬, 李岩, 韩菲. 2021. 桂中-南盘江地区黔水地1井钻井关键技术[J]. 断块油气田, 28(3): 423-427. https://www.cnki.com.cn/Article/CJFDTOTAL-DKYT202103027.htm 郭军, 王超技, 李岩, 苑坤, 王文彬. 2020. 跟管钻进在大口径页岩气井浅部复杂地层中的应用——以黔水地1井导管段为例[J]. 探矿工程(岩土钻掘工程), 47(5): 22-26. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202005005.htm 郝海洋, 宋继伟, 蒋国盛, 杜胜江, 李勇, 班金彭, 黄明勇, 畅利民. 2019. 南方页岩气基础地质调查黔普地1井钻井施工技术[J]. 探矿工程(岩土钻掘工程), 46(8): 23-29. 侯婷, 宁学涛, 王斌, 吴柳根. 2015. 膨胀套管技术在钻井完井工程中的应用研究[J]. 中外能源, 20(6): 48-51. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZW201506009.htm 侯子旭, 贾晓斌, 李双贵, 邓文良, 曾德智. 2013. 玉北地区深部地层扭力冲击器提速工艺[J]. 石油钻采工艺, 35(5): 132-136. doi: 10.3969/j.issn.1000-7393.2013.05.038 黄晟辉, 奎中, 吴金生, 赵元刚, 房昕. 2019. 湘永地1井钻进施工及事故处理技术[J]. 探矿工程(岩土钻掘工程), 46(2): 23-29. 李浩涵, 杜江, 陈科, 李飞, 宋腾, 王鹏. 2020. 湖北五峰地区发现二叠系页岩气[J]. 中国地质, 47(6): 1932-1933. http://geochina.cgs.gov.cn/geochina/article/abstract/20200629?st=search 李娟, 王玉芳, 翟刚毅, 张家政. 2021. 陕西南郑地区第一口参数井钻获牛蹄塘组页岩气[J]. 中国地质, 48(1): 337-338. http://geochina.cgs.gov.cn/geochina/article/abstract/20210125?st=search 李小洋, 李宽, 张永勤, 梁健, 吴纪修, 王志刚. 2019. 新型涡轮扭力冲击器的试验研究[J]. 探矿工程(岩土钻掘工程), 46(12): 40-43, 49. 李岩, 郭军, 王文彬. 2021. 滇东地区页岩气调查云宣地1井钻探施工难点及对策[J]. 钻探工程, 48(8): 12-18. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202108002.htm 廖圣兵, 石刚, 李建青, 郑红军, 周道容, 王存智, 黄宁. 2021. 安徽望江地区WWD1井钻遇二叠系孤峰组页岩气[J]. 中国地质, 48(5): 1657-1658. http://geochina.cgs.gov.cn/geochina/article/abstract/20210526?st=search 刘兵, 朱恒银, 蔡正水, 王强, 芦文成. 2020. 宁国凹陷复杂工况关键钻井工艺[J]. 科学技术与工程, 20(22): 8943-8947 https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202022013.htm 刘笑傲, 邹德永, 陈修平. 2017. 强研磨性硬地层聚晶金刚石复合片孕镶块混合钻头优化设计试验[J]. 科学技术与工程, 17(29): 220-226. 刘协鲁, 阮海龙, 赵义, 蔡家品, 陈云龙, 梁涛, 李春, 刘海龙, 邓都都. 2021. 海域天然气水合物保温保压取样钻具研究与应用进展[J]. 钻探工程, 48(7): 33-39. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202107006.htm 刘治. 2017. 小口径岩心钻探技术在页岩气地质调查井中的应用分析[J]. 探矿工程(岩土钻掘工程), 44(9): 32-37. 庞飞, 张作衡, 张君峰, 陈科, 石砥石, 包书景, 李世臻, 郭天旭. 2020. 长江经济带页岩气勘探开发进展及建议[J]. 地球科学, 45(6): 2152-2159. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202006026.htm 彭粲璨, 李奋强, 吴聪, 韦又林. 2013. 页岩气参数井小井眼钻井技术——以常页1井为例[J]. 中国煤炭地质, 25(11): 55-58. 彭奋飞, 王佳亮, 万步炎, 黄筱军, 唐永辉, 彭德平. 2021. 适用于海底钻机的保压绳索取心钻具设计[J]. 钻探工程, 48(4): 97-103. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202104013.htm 齐列锋. 2016. 新型液压式扭力冲击器设计与动力仿真[D]. 荆州: 长江大学. 覃英伦, 张家政, 王玉芳, 康海霞, 李娟, 张子亚, 薛宗安, 张云枭. 2021. 广西桂中坳陷(桂融页1井)石炭系鹿寨组获页岩气重要发现[J]. 中国地质, 48(2): 667-668. http://geochina.cgs.gov.cn/geochina/article/abstract/20210225?st=search 单文军, 段晓青, 任福建, 张伟华, 岳伟民, 李艳宁. 2016a. 甘肃武威盆地页岩气"武页1井"成膜低固相冲洗液的应用[J]. 探矿工程(岩土钻掘工程), 43(7): 111-115. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC201607023.htm 单文军, 蒋睿, 陶士先, 岳伟民, 李艳宁. 2016b. 页岩气钻探冲洗液体系的研究与应用[J]. 探矿工程(岩土钻掘工程), 43(10): 176-181. 石刚, 李建青, 廖圣兵, 吴通, 黄宁, 方朝刚, 黄正清, 邵威, 叶隽, 蔡小虎, 张强. 2021. 安徽宣城地区皖油地1井钻获二叠系页岩气[J]. 中国地质, 48(2): 669-670. http://geochina.cgs.gov.cn/geochina/article/abstract/20210226?st=search 宋腾, 陈科, 包书景, 郭天旭, 雷玉雪, 王亿, 孟凡洋, 王鹏. 2018. 鄂西北神农架背斜北翼(鄂红地1井)五峰-龙马溪组钻获页岩气显示[J]. 中国地质, 45(1): 195-196. http://geochina.cgs.gov.cn/geochina/article/abstract/20180117?st=search 苏舟, 张绍和, 王文彬, 曹函, 刘磊磊, 肖金成, 何红生, 郭军. 2021. 黔水地1井钻探施工技术难点及对策[J]. 钻探工程, 48(5): 54-59. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202105008.htm 滕龙, 方朝刚, 郑红军, 翟刚毅, 李建青, 黄正清, 王敬东, 张号, 吕星. 2019. 萍乐坳陷中部(赣丰地1井)二叠系乐平组获"三气"发现[J]. 中国地质, 46 (1): 203-204. http://geochina.cgs.gov.cn/geochina/article/abstract/20190113?st=search 王滨, 李军, 邹德永, 杨宏伟, 黄涛. 2018a. 强研磨性硬岩PDC钻头磨损机理及磨损分布规律研究[J]. 特种油气藏, 25(4): 149-153. https://www.cnki.com.cn/Article/CJFDTOTAL-TZCZ201804030.htm 王滨, 李军, 邹德永, 杨宏伟, 王凯. 2018b. 适合强研磨性硬地层PDC-金刚石孕镶块混合钻头设计与应用[J]. 特种油气藏, 25(1): 169-174. 王红希. 2018. 旋冲式扭力冲击器结构设计及参数优化研究[D]. 青岛: 中国石油大学(华东). 王杰. 2015. 钻井用双作用扭力冲击器设计计算与仿真[D]. 北京: 中国地质大学(北京). 吴柳根, 宁学涛, 唐明. 2013. 等井径膨胀套管技术应急应用研究[J]. 钻采工艺, 36(6): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-ZCGY201306002.htm 伍晓龙, 朱芝同, 董向宇, 李文秀. 2019. 小口径油气地质调查井的问题与工程实践[J]. 探矿工程(岩土钻掘工程), 46(11): 27-32. 熊虎林, 张飞, 甘辉敏, 徐龙生. 2019. 页岩气调查泉参1井大口径同径取心钻进工艺[J]. 探矿工程(岩土钻掘工程), 46(6): 19-25. 徐云龙, 王锐, 王文斐, 刘建刚. 2014. TP131HCH超深五段制侧钻水平井优快钻井技术[J]. 探矿工程(岩土钻掘工程), 41(10): 22-25. 杨顺辉, 武好杰, 牛成成, 侯绪田, 金军斌. 2014. 特种孕镶块加强PDC钻头的研制与实验[J]. 石油钻探技术, 42(6): 111-114. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZT201406027.htm 杨现禹, 蔡记华, 蒋国盛, 石彦平, 陈书雅, 魏朝晖, 谢章建. 2021. 维持页岩井壁稳定的物理封堵模拟和化学抑制实验研究[J]. 钻探工程, 48(4): 37-46. 于金平, 邹德永, 刘笑傲. 2020. 适合强研磨性硬地层的新型混合钻头设计及现场应用[J]. 金刚石与磨料磨具工程, 40(3): 67-71. https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM202003012.htm 苑坤, 王超, 覃英伦, 于抒放, 陈榕, 石砥石, 包书景, 林拓, 周志. 2017. 黔南地区(黔紫页1井)发现上古生界海相页岩气[J]. 中国地质, 44(6): 1253-1254. http://geochina.cgs.gov.cn/geochina/article/abstract/20170618?st=search 翟刚毅, 包书景, 庞飞, 任收麦, 陈科, 王玉芳, 周志, 王胜建. 2017. 贵州遵义地区安场向斜"四层楼"页岩油气成藏模式研究[J]. 中国地质, 44(1): 1-12. http://geochina.cgs.gov.cn/geochina/article/abstract/20170101?st=search 张保民, 蔡全升, 陈孝红, 王传尚, 张国涛, 陈林, 李培军, 李炎桂. 2021. 鄂西黄陵隆起东缘鄂宜页2井五峰组-龙马溪组页岩气储层特征与含气性[J]. 中国地质, 48(5): 1485-1498. http://geochina.cgs.gov.cn/geochina/article/abstract/20210513?st=search 张德龙, 翁炜, 贾军, 黄玉文, 冯美贵. 2015. 干热岩钻探井控技术研究[J]. 科技导报, 33(19): 45-48. 张福, 黄艺, 蓝宝峰, 李龙, 刘婷, 刘睿, 江定川. 2021. 正安地区五峰组-龙马溪组页岩储层特征及控制因素[J]. 地质科技通报, 40(1): 49-56. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202101005.htm 张恒春, 王稳石, 李宽, 王跃伟, 闫家, 曹龙龙, 胡晨. 2021. KT178型取心钻具在共和干热岩钻井中的应用[J]. 钻探工程, 48(2): 29-34. 张文浩, 高永进, 周新桂, 翟刚毅, 徐兴友, 白忠凯, 周志, 毕彩芹, 单衍胜, 韩淼, 孙相灿, 张远银, 刘卫彬. 2021. 公益性油气基础地质调查的进展与发展方向[J]. 地质学报, 95(5): 1630-1643. 张子亚, 张聪, 石砥石, 覃英伦, 陈榕, 康海霞. 2019. 宁蒗-盐源地区(云宁地1井)泥盆系获天然气重大发现[J]. 中国地质, 46(2): 432-433. http://geochina.cgs.gov.cn/geochina/article/abstract/20190220?st=search 赵洪波, 单文军, 朱迪斯, 岳伟民, 何远信. 2021. 裂缝性地层漏失机理及堵漏材料新进展[J]. 油田化学, 38(4): 740-746. https://www.cnki.com.cn/Article/CJFDTOTAL-YJHX202104027.htm 赵洪波, 朱迪斯, 黄正, 王胜建, 何远信. 2020. 南华北盆地亳州-阜阳地区页岩气钻井技术[J]. 石油钻采工艺, 42(6): 679-683. 赵莉萍, 王倩, 郭正, 房超, 曹虎. 2020. 基于有限坍塌宽度的层理性泥页岩地层井壁稳定性评价[J]. 科技导报, 38(11): 122-130. 赵文智, 贾爱林, 位云生, 王军磊, 朱汉卿. 2020. 中国页岩气勘探开发进展及发展展望[J]. 中国石油勘探, 25(1): 31-44. https://www.cnki.com.cn/Article/CJFDTOTAL-KTSY202001004.htm 赵远刚, 吴琳, 石绍云, 钱锋, 黄晟辉, 黄晓林. 2021. 地质调查预算分列钻探项目管理模式创新研究与实践[J]. 钻探工程, 48(4): 54-59. 郑红军, 周道容, 殷启春, 熊强青, 王中鹏, 方朝刚, 滕龙, 邵威, 王元俊. 2020. 下扬子页岩气地质调查新进展及突破难点思考[J]. 地质力学学报, 26(6): 852-871. 周志, 包书景, 陈科, 徐秋枫, 张守松, 王超, 王鹏. 2018. 湖北建始地区二叠系鄂建业1井钻获页岩气[J]. 中国地质, 45(6): 1304-1305. http://geochina.cgs.gov.cn/geochina/article/abstract/20180619?st=search 周志, 李世臻, 陈科, 李浩涵, 李飞, 徐桂红. 2020. 湖北秭归地区发现志留系页岩气[J]. 中国地质, 47(3): 881-882. http://geochina.cgs.gov.cn/geochina/article/abstract/20200324?st=search 朱迪斯, 岳伟民, 单文军, 赵洪波, 翁炜. 2020. 页岩气地质调查井浙桐地1井钻探施工技术[J]. 探矿工程(岩土钻掘工程), 47(9): 15-20. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202009003.htm 朱恒银, 王强, 田波, 王久全. 2016a. 大直径加重管组合绳索取心钻具研究与应用[J]. 地质与勘探, 52(6): 1159-1166. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT201606017.htm 朱恒银, 王强, 张正, 蔡正水. 2016b. 大直径加重管绳索取心技术在页岩气勘探中的应用研究[J]. 探矿工程(岩土钻掘工程), 43(10): 160-164. 朱恒银, 王强. 2013. 页岩气勘探开发技术综述[J]. 安徽地质, 23(1): 21-25. https://www.cnki.com.cn/Article/CJFDTOTAL-AHDZ201301007.htm 朱永宜, 王稳石, 张恒春, 闫家, 曹龙龙, 许洁, 孟庆鸿, 谈晓丽. 2018. 我国大陆科学钻探工程实施概况及其取心钻进技术体系[J]. 地质学报, 92(10): 1971-1984. 朱芝同, 伍晓龙, 董向宇, 曹龙龙, 和国磊, 张德军. 2019. 松辽盆地页岩油勘探大口径取心技术[J]. 探矿工程(岩土钻掘工程), 46(1): 45-50. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC201901008.htm -

期刊类型引用(6)

1. 韩双宝,周殷竹,郑焰,周金龙,李长青,韩强强,李甫成. 银川平原地下水化学成因机制与组分来源解析. 环境科学. 2024(08): 4577-4588 .  百度学术

百度学术

2. 张卓,郭华明,韩双宝,牛笑童. 沉积物中砷的赋存特征及对地下水砷富集的控制:以内蒙古河套盆地为例. 中国地质. 2024(04): 1331-1341 .  本站查看

本站查看

3. 吴光伟,李浩林,王庆兵,顾莎,郭梓烽,刘中业. 鲁西北平原地下水高氟与高碘成因分析. 岩矿测试. 2023(04): 793-808 .  百度学术

百度学术

4. 张卓,柳富田,陈社明. 氢氧、锶钙和锂硼同位素在高氟地下水研究中的应用. 华北地质. 2023(03): 49-56 .  百度学术

百度学术

5. 李红超,单强,马丙太,赵德刚. 基于逻辑回归分析的焦化行业地下水有机污染物分布特征及影响因素研究. 华北地质. 2023(04): 47-54 .  百度学术

百度学术

6. 邢世平,郭华明,吴萍,胡学达,赵振,袁有靖. 化隆—循化盆地不同类型含水层组高氟地下水的分布及形成过程. 地学前缘. 2022(03): 115-128 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: